In today’s fast-paced world, the demand for high-quality instant coffee products is skyrocketing. As a forward-thinking business, staying ahead of the curve is crucial, and investing in a cutting-edge Instant Coffee Processing System can be the key to unlocking new realms of efficiency, consistency, and profitability. Whether you refer to it as a Soluble Coffee Processing System or a Coffee Powder Processing System, this remarkable technology offers a comprehensive solution for transforming freshly brewed coffee into a premium, soluble powder form.

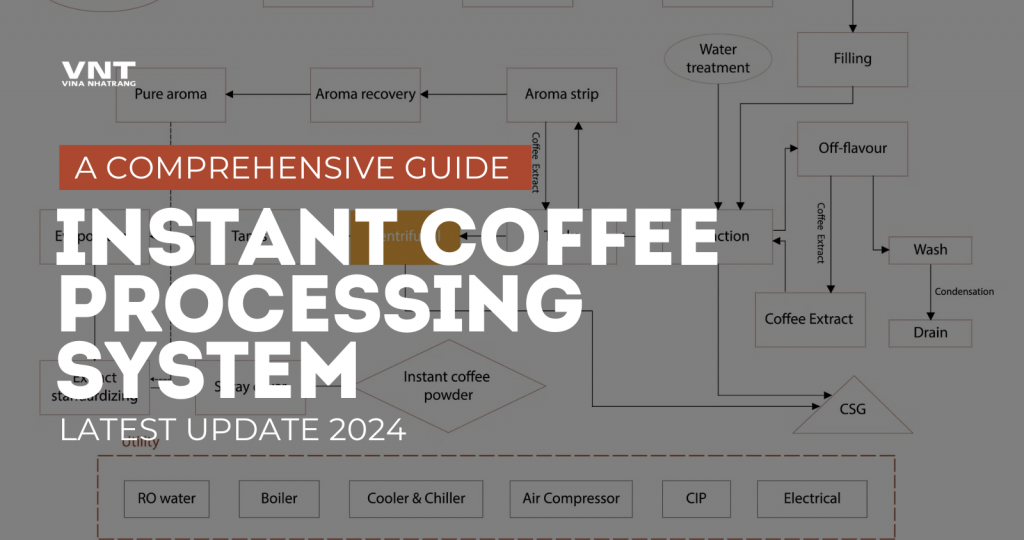

Instant Coffee Processing System P&ID Diagram

See what machines is used in a Instant Coffee Processing System

Instant Coffee Extraction System – Unparalleled Extraction Efficiency

VNT’s Instant Coffee Extraction System

The journey begins with a state-of-the-art extraction system, where finely ground coffee beans are brewed in highly efficient extraction equipment. Precise temperatures and pressures are maintained as hot water is processed through multiple columns of ground coffee, ensuring optimal extraction of even the most intricate coffee components, including carbohydrates. This advanced process yields a concentrated coffee extract containing approximately 20-23% solids, laying the foundation for a superior final product.

The VNT‘s Instant Coffee Extraction System offers a sophisticated solution for coffee producers seeking to optimize instant coffee production. This system prioritizes both efficiency and quality, making it a valuable asset for manufacturers aiming to maximize yield and deliver a superior final product.

Find out more about VNT‘s Instant Coffee Extraction System

Instant Coffee Aroma Recovery System – Preserving the Authentic Aroma

VNT’s Instant Coffee Aroma Recovery System

One of the most significant challenges in instant coffee production is retaining the authentic aroma that coffee connoisseurs crave. Our cutting-edge Aroma Recovery System addresses this issue head-on, employing two innovative methods to capture and reincorporate the aromatic volatiles lost during the extraction and drying stages.

- Head Space Gas Recovery System: In this groundbreaking approach, coffee is ground in a closed environment, followed by flushing with inert gas. The aroma compounds are then expertly stripped from the inert gas at low temperatures and recovered as a frozen mass, preserving their integrity.

- Extract Stripping System: During the percolation stage, just before extraction, ground coffee is subjected to steam, which carries the aroma components. The aroma-laden steam is then condensed, and the aroma fraction is separated, purified, and concentrated, ensuring that every nuance is captured.

The recovered aroma can be seamlessly integrated into your instant coffee powder through various techniques, such as passing aroma-loaded gas over the coffee, mixing with coffee oil, encapsulating in sodium alginate or gelatin, or allowing the instant coffee to absorb flavoring compounds from roasted coffee beans.

The VNT‘s Instant Coffee Aroma Recovery System ushers in a new era for instant coffee production by addressing a key challenge – capturing the rich aroma and flavor profile of freshly brewed coffee.

Find out more about VNT‘s Instant Coffee Aroma Recovery System

Instant Coffee Evaporation System – Precision Concentration and Evaporation

VNT’s Instant Coffee Evaporation System

The VNT‘s Instant Coffee Evaporation System plays a vital role in high-quality instant coffee production:

After the aroma recovery process, our advanced evaporation system concentrates the coffee extract further, reducing the cost of spray drying while maintaining the exceptional quality and taste of your final product. Our state-of-the-art concentration process is designed to achieve a solids extraction concentration of 50%, guaranteeing that every batch retains its fragrance and flavor, consistently delighting your customers.

Find out more about VNT‘s Instant Coffee Evaporation System

Instant Coffee Spray Dryer – Unmatched Spray Drying Technology

Instant Coffee Spray Dryer

At the heart of our Instant Coffee Processing System lies our cutting-edge spray drying technology, which transforms the liquid coffee extract into a dry, soluble powder form with unparalleled precision and efficiency. The combination of spray drying and a low drying temperature range (160°C – 185°C) creates a gentle drying process that helps safeguard the volatile aromatic compounds responsible for the coffee’s flavor and aroma.

The dry coffee powder is collected at the bottom of the tower and can undergo agglomeration to form coarser particles, ensuring optimal dissolution and an exceptional user experience. Our spray drying process is both effective and economical, ensuring the highest quality and uncompromising taste in every batch of your instant coffee product.

Additionally, the system offers remarkable adjustability. You can tailor the density (200-320 g/l) and moisture content (less than 5%) of the final coffee powder to meet your specific needs and market preferences.

Find out more about VNT’s Instant Coffee Spray Dryer

Conclusion:

In the competitive world of coffee production, investing in a state-of-the-art Instant Coffee Processing System is not just a wise business decision – it’s a game-changer. With our cutting-edge technology, you can unlock new levels of efficiency, consistency, and profitability, while delivering a superior instant coffee product that will captivate your customers’ taste buds. Contact us today to learn how our Soluble Coffee Processing System or Coffee Powder Processing System can elevate your business and solidify your position as a leader in the industry.