Evaporation technology is often hailed as a game-changer in food processing, enabling manufacturers to strip water from liquid products, leaving behind concentrated forms packed with flavor, aroma, and nutrients. It’s efficient, yes, but also deeply transformative, taking food from its natural state and reshaping it for industrial convenience. From condensed milk to fruit juices and savory sauces, this process has evolved from basic boiling methods to high-tech, automated systems that prioritize scalability and energy efficiency over raw authenticity.

While its versatility and precision are undeniable, evaporation technology raises questions about what we sacrifice in pursuit of shelf stability and portability. Are we truly enhancing food, or merely commodifying it for mass production? In this blog, we’ll break down the science, applications, and implications of evaporation technology, exploring whether it’s an essential innovation or another step away from food’s natural integrity.

Table of Contents

ToggleIntroduction to Evaporation Technology in Food Processing

Evaporation technology has been a cornerstone of the food industry for over a century. It plays a critical role in preserving food, extending shelf life, and reducing transportation costs.

But what makes it truly indispensable? Evaporation operates on a simple principle: by raising the temperature of water in food to its boiling point, the water is removed through evaporation. This method is highly efficient, allowing for large volumes of concentrated products to be produced quickly, making it particularly prevalent in industries such as fruit juice, dairy, jam and marmalade, sugar production, and vegetable pulp processing.

Who Pioneered the Technology?

The concept of evaporation in food processing dates back to 1856, when Borden introduced the first evaporation machine for commercial use. His innovation in sweetened condensed milk revolutionized food preservation. Since then, the technology has evolved—from open kettles to revolving steam coils and now, modern forced or natural circulation evaporators. This progression has not only improved efficiency but also enabled the large-scale production of concentrated liquid foods like milk, juices, and syrups.

💡 Did you know?

The first recorded use of evaporation for food preservation dates back to ancient times when people boiled milk to reduce its volume and extend its shelf life—a precursor to modern condensed milk!

Why Is Evaporation So Important?

Water is crucial in the food industry. It impacts everything from a product’s physical properties to its microbiological stability. Evaporation technology helps to manage this essential element. By removing water, we not only improve the product’s shelf life but also enhance the safety and taste by preventing microbial growth.

Explore more: Instant Coffee Evaporation System

How Does Evaporation Work in Food Processing?

At its core, evaporation is a heat-driven process. The goal is simple: remove water from liquid food to concentrate it, without drying it completely. Here’s how it works:

- Heat Transfer: The process begins by using low-pressure steam to heat the food product to its boiling point. This heat transforms the latent energy in the steam into thermal energy for the liquid food.

- Water Removal: As the product reaches its boiling point, water vaporizes and is separated from the food, leaving behind a more concentrated form.

- Evaporator Design: The evaporation process occurs inside a chamber with an indirect heat exchanger. These evaporators can function using either forced or natural circulation, depending on the setup.

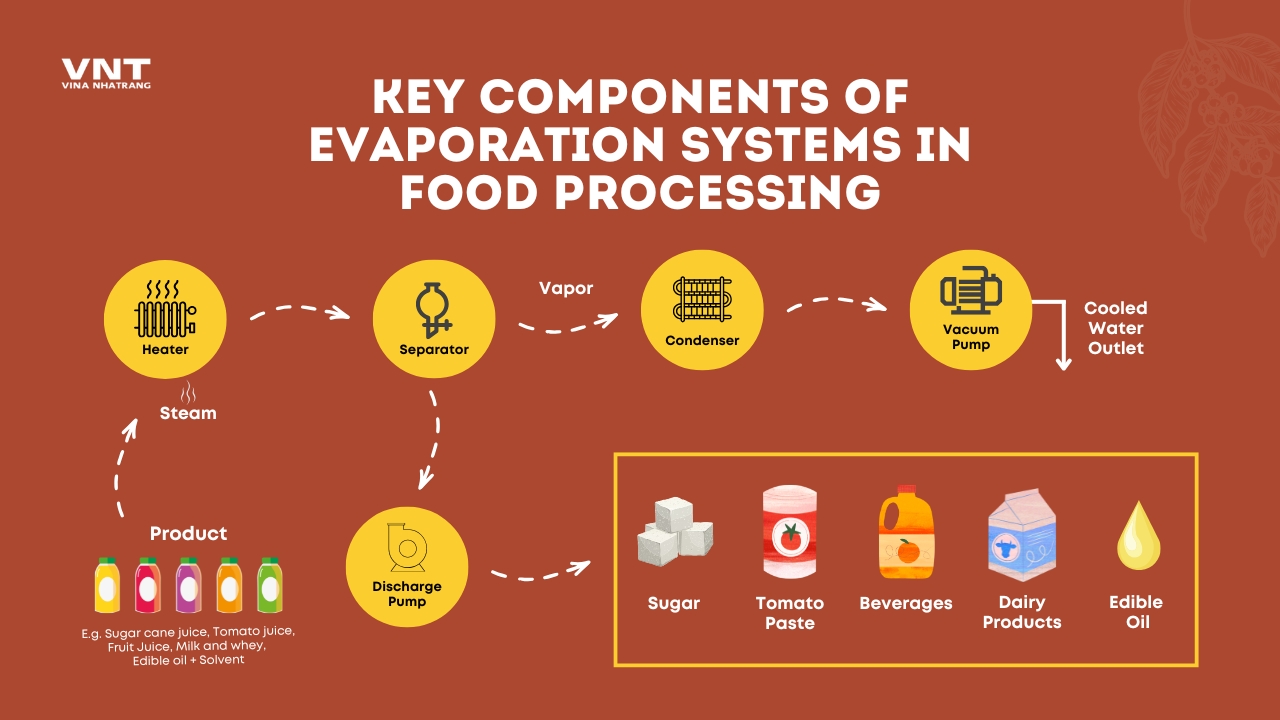

Key components of evaporation systems in food processing and general unit operation

This method is distinct because it operates primarily at the boiling point, meaning it doesn’t dry out the food—just concentrates it. That’s why you often see evaporated products in their liquid form, such as juices or milk, which still contain moisture but are much more concentrated than their original state.

Evaporation vs. Other Concentration Techniques

While evaporation is an effective and widely used method, it’s not the only option. Other techniques, such as vacuum evaporation, freeze concentration, and reverse osmosis, are also available. However, these alternatives come with their own set of challenges, such as high installation and maintenance costs, extended processing times, and limitations on the maximum concentration achievable.

In contrast, evaporation remains a reliable and cost-effective solution for food manufacturers looking to produce concentrated products without sacrificing too much quality or incurring excessive costs. And while it does have its drawbacks—like the need for precise temperature control and potential energy consumption—the benefits it offers in terms of product preservation and transportation efficiency make it a staple in the food industry.

Different Types of Evaporators in the Food Industry

Evaporation is crucial in food processing, and different types of evaporators are used based on the product, energy efficiency, and process requirements. The most common evaporators are single-effect, multiple-effect, and those with vapor recompression systems. Key components of evaporation units include the heater, vapor separator, condenser, discharge pump, and vacuum pump, each playing a specific role in the evaporation process.

Atmospheric Evaporation: Simple but Inefficient

- In atmospheric evaporation, the liquid is heated in an open container, and the vapor escapes into the atmosphere. This method is slow, energy-inefficient, and can negatively impact product quality, making it less ideal for high-value products.

Vacuum Evaporation: Controlled Environment with High Energy Usage

- Vacuum evaporation lowers the boiling point by reducing pressure, making it suitable for heat-sensitive foods. However, it still consumes a lot of energy and has room for improvement in terms of reducing processing time and enhancing efficiency. Research into alternative heating methods aims to address these issues.

Single-Effect Evaporators: Basic but Energy-Intensive

- A single-effect evaporator uses high-pressure steam to heat the liquid in a steam-jacketed container. The steam is used once, making this method less energy-efficient but simpler for batch processing.

Learn more: Understanding Single-Effect Evaporators in Food Processing

Multiple-Effect Evaporators: Energy-Efficient but Complex

- Multiple-effect evaporators use several connected units where steam from one unit is reused in the next, reducing steam consumption and improving efficiency. However, higher temperatures and longer retention times can affect product quality.

Explore more: Comprehensive Guide to Multiple-Effect Evaporators in Food Processing

Rising and Falling Film Evaporators: For Viscous Liquids

- Rising film evaporators (RFEs) are ideal for low-viscosity liquids, where vapor helps move the liquid upward in the tubes. Falling film evaporators distribute liquid evenly across the heating surface, making them suitable for both heat-sensitive and viscous products. Sometimes, both types are used in tandem for pre-concentration and final concentration.

Agitated Film Evaporators: For Viscous, Heat-Sensitive Products

- Agitated film evaporators are designed for highly viscous or particle-laden substances. The rotor blades agitate the liquid, improving heat transfer and preventing fouling, making them perfect for challenging products.

Applications in the Food Industry

Evaporation technology has a wide array of applications in the food industry, making it indispensable for manufacturers aiming to enhance product quality and shelf life. Its versatility allows it to process various food products efficiently, delivering concentrated forms that retain their nutritional and sensory attributes.

Dairy Products: Condensed Milk and Beyond

In dairy processing, evaporation is primarily used to produce condensed milk. By evaporating water from skim or whole milk, the dry matter ratio of the milk increases by approximately twofold. Condensed milk is often packaged for direct consumer consumption but can also serve as an intermediate ingredient in dried milk or flavoring for beverages, puddings, and ice cream.

Since milk is heat-sensitive, evaporation is typically done under vacuum conditions, lowering the boiling point and minimizing quality degradation. This helps maintain the milk’s flavor and texture. The process does, however, lead to lactose crystallization, which can affect the product’s texture. Stabilizers are often added to improve the milk’s thermal stability and reduce coagulation.

Evaporated milk also plays a crucial role in cheese production. Concentrating milk before cheese-making increases cheese yield, reduces whey volume, and improves efficiency. Studies show that milk concentrated via vacuum evaporation affects the final cheese’s moisture, protein, and calcium content.

Sugar Manufacturing: Enhancing Raw Sugar Production

Evaporation is also essential in the sugar industry, where it is used to concentrate sugar juice from sugarcane. This helps transform the diluted juice into raw sugar and molasses. However, exposing the juice to high heat can lead to sucrose inversion, where sucrose breaks down into glucose and fructose, affecting the quality of the final product. Multiple-effect evaporators are typically used to reduce energy costs and improve efficiency, but fouling during the process remains a challenge.

Fruit Juice: Preserving Flavor and Reducing Transport Costs

In the fruit juice industry, evaporation is widely used to concentrate juice, lowering its water content and reducing storage, packaging, and shipping costs. However, the process has some drawbacks—traditional evaporation causes the loss of volatile compounds like vitamins and flavor molecules, which can result in a cooked taste and the formation of harmful compounds like hydroxymethyl furfural. Therefore, maintaining a balance between concentration and quality preservation is key.

Tomato Paste: Concentrating for Long-Term Storage

In the tomato industry, evaporators concentrate tomato juice into paste, which can be stored for extended periods. The concentration of tomato paste improves its texture, color, and nutritional value. Using vacuum evaporation can enhance the lycopene content, a crucial antioxidant found in tomatoes, making the process more efficient than traditional atmospheric methods.

Edible Oils: Solvent Recovery

In the edible oil industry, evaporators are used for solvent recovery after oil extraction. The solvent, typically hexane, is removed from the oil using a double-effect evaporator and steam stripping methods, ensuring that the oil remains pure and the solvent is recycled. This is a critical step in maximizing the yield of extracted oil while minimizing waste and ensuring safety.

Wastewater Treatment and Environmental Benefits

Evaporators are also utilized to manage wastewater in the food industry, helping to reduce environmental impact. For example, coconut water from the desiccated coconut industry and potato wastewater from the starch industry are evaporated to produce alternative products like fertilizers. This not only reduces waste but also creates valuable byproducts that can be used in other applications.

Challenges to Overcome

Despite its advantages, evaporation is not without its challenges. Key limitations include:

- Concentration Limits: Certain foods may not achieve the desired concentration due to the nature of their composition or the evaporation technology itself.

- Energy Costs: The significant energy requirements, primarily driven by the use of steam as the heating medium, contribute to high operational costs. This is particularly concerning in large-scale operations.

- Processing Time: Even with advanced systems, the time required to achieve the desired concentration can still be lengthy, especially in large quantities.

These drawbacks necessitate the development of more efficient systems that balance energy use, processing time, and cost-effectiveness.

Economic and Energy Considerations

A critical aspect of improving evaporation systems is finding a balance between energy savings and investment costs. While more advanced systems, such as multiple-effect evaporators, can lower energy consumption, they often require significant capital investment. The key to optimizing these systems lies in determining the optimal number of stages for evaporation. This is where tools like exergy and energy analysis come into play, helping manufacturers assess the most economically viable configurations for their operations.

💡 Did you know?

Solar-powered evaporation systems are already being tested in remote areas, paving the way for sustainable food processing with minimal environmental impact.

Innovative Designs for the Future

To address the limitations of traditional evaporation methods, new design innovations have been explored. For example:

- Microwave Heating: By integrating microwave energy into the evaporation process, it is possible to reduce processing times while preserving the quality of the food.

- Ohmic Heating: This technique, which uses an electric current to heat food, can also improve efficiency by allowing for faster and more uniform heating, ultimately saving both time and energy.

Such innovations hold the promise of lowering costs, improving energy efficiency, and ultimately making evaporation systems more sustainable for the food industry.

Final Thoughts

Evaporation remains a cornerstone of food processing, with a broad range of applications and an established track record in improving shelf life, reducing weight, and concentrating flavors. However, as the industry evolves, so must the systems that drive it. By embracing innovative technologies and focusing on energy efficiency, manufacturers can overcome the current limitations of evaporation, reduce operational costs, and deliver better quality products to consumers. Ultimately, the continued development of evaporation systems will shape the future of food processing—helping to meet the growing demand for sustainable and high-quality food products.

FAQs

❓ What is evaporation in food processing?

- Evaporation in food processing is a unit operation used to concentrate liquid food products by removing a portion of the water content through heating. It involves the transformation of latent heat into the food product, raising its temperature to the boiling point to facilitate the removal of water. The process improves product shelf life, reduces transportation costs, and enhances microbiological stability.

❓ How does evaporation differ from dehydration?

- Evaporation removes water from liquids to concentrate them, retaining much of the original product’s flavor and nutrients. Dehydration, on the other hand, removes almost all moisture, resulting in a dry product.

❓ Can evaporation technology be used for wastewater treatment in the food industry?

- Yes, evaporation is used in some food industries to handle wastewater, particularly those that are difficult to treat using conventional methods. For instance:

- Potato wastewater in the potato starch industry and coconut water from the desiccated coconut industry can be evaporated to reduce water content, making them usable for other purposes such as fertilizers or alternative products.

- This helps reduce the environmental impact of food industry waste and provides a more sustainable approach to waste management.

❓ What are the benefits of using vacuum evaporators?

- Vacuum evaporators allow for evaporation at lower temperatures, making them ideal for heat-sensitive products. They preserve nutrients, flavors, and colors better than traditional systems.

❓ How can food manufacturers reduce the operational costs of evaporation systems?

- To reduce operational costs, food manufacturers can:

- Invest in energy-efficient systems: Using multi-effect evaporators or systems that recycle heat reduces energy consumption.

- Optimize steam usage: By using exhaust steam or implementing low-pressure systems, steam costs can be minimized.

- Regular maintenance: Preventative maintenance reduces fouling, corrosion, and downtime, ensuring systems run efficiently.

- Advanced heating technologies: Implementing microwave-assisted or ohmic heating methods can reduce both energy costs and processing time.

Conclusion

Evaporation technology is a cornerstone of modern food processing, offering unmatched efficiency, versatility, and sustainability. From concentrating fruit juices to creating dairy and herbal products, it continues to shape the food industry. As innovations emerge, the potential for evaporation technology to transform processes and meet consumer expectations is boundless.

Reference: Evaporation Technology in Food Processing [Book Title].