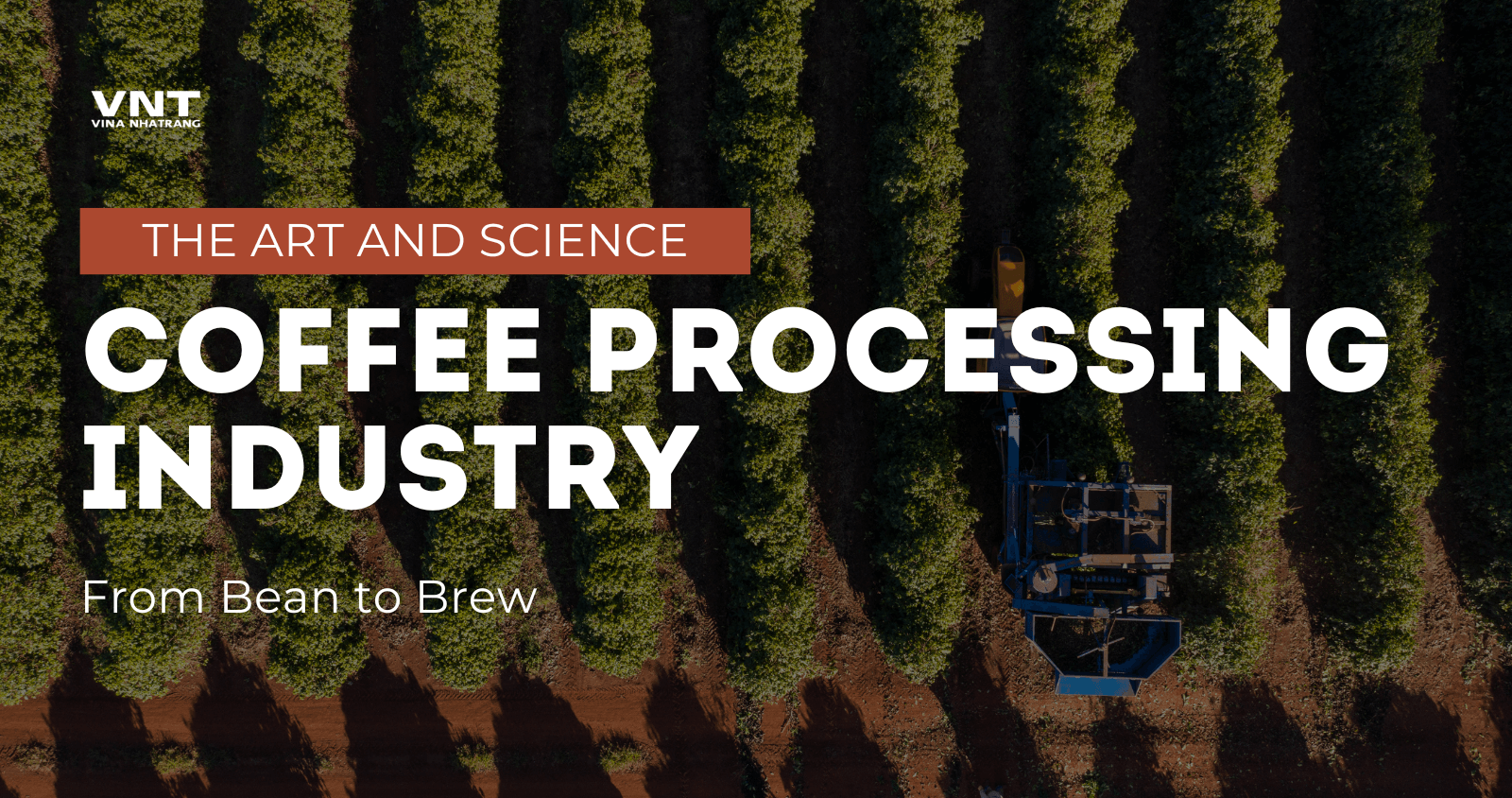

Today, we’re diving deep into the fascinating world of industrial coffee processing. This isn’t just about plucking beans from trees – it’s an intricate dance of science, art, and tradition that transforms raw coffee cherries into the aromatic beans we know and love. So grab your favorite mug, and let’s explore how the coffee processing industry crafts the perfect bean!

Explore more: Choosing the Right Coffee Roaster Equipment for Your Business

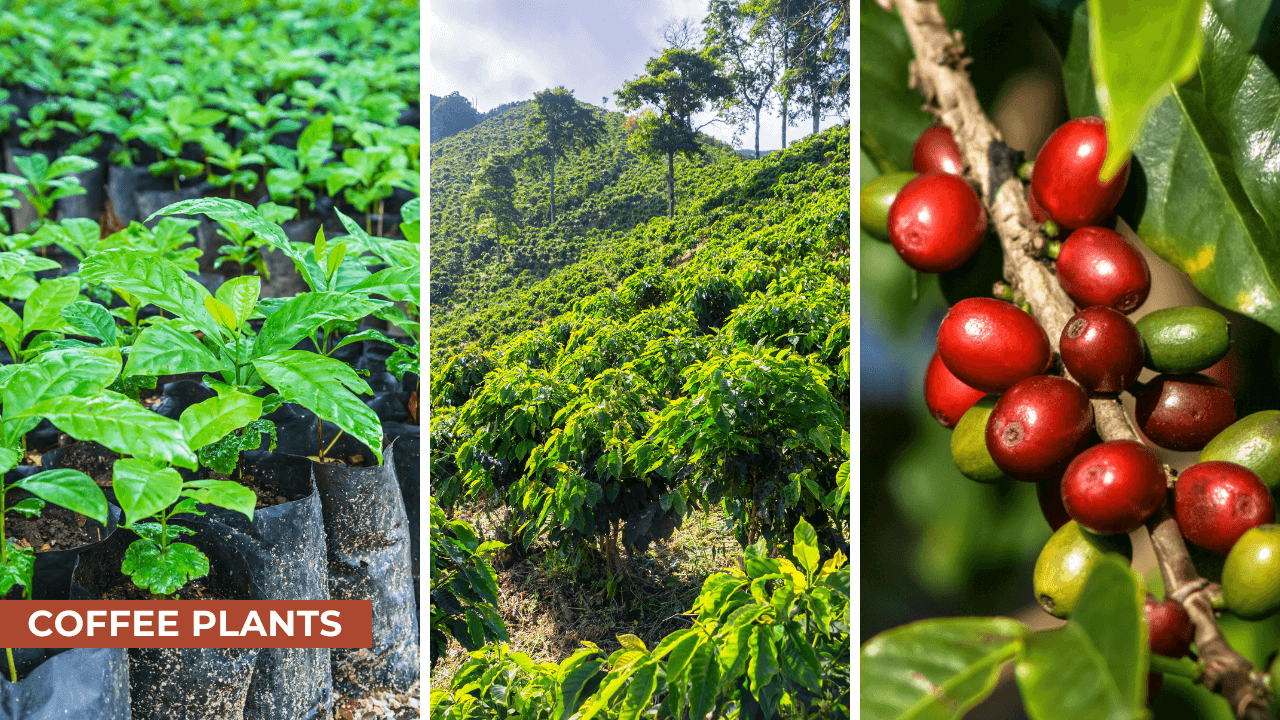

The Coffee Cherry: Where It All Begins

Coffee plants are actually evergreen shrubs or small trees of the genus Coffea, part of the family Rubiaceae. The two most economically important species of coffee plants are Coffea arabica (Arabica coffee) and Coffea canephora (Robusta coffee). Arabica coffee, which accounts for about 70% of the world’s production, is considered superior in taste and aroma compared to Robusta.

These plants thrive in tropical and subtropical regions, typically between latitudes 25° N and 25° S. The ideal growing conditions include:

- Temperatures between 60°F to 70°F (15°C to 21°C)

- Annual rainfall of 60 to 80 inches (1,500 to 2,000 mm)

- Well-drained, slightly acidic soil

💡 Fun fact

Did you know that coffee cherries are actually edible? They have a sweet, slightly tart flavor reminiscent of watermelon or hibiscus. While not commonly consumed, some innovative companies are now using coffee cherry flesh to create cascara, a tea-like beverage.

Coffee plants thrive in warm, wet climates and can live for over 50 years

The Journey from Seed to Harvest

Before we dive into processing, it’s worth understanding the journey of coffee from seed to harvest. This process typically takes 3-4 years:

- Seedling Stage: Seeds are planted in nurseries and carefully tended for about 6 months.

- Transplanting: Young plants are moved to the main growing fields.

- Maturation: It takes about 3 years for a new plant to bear fruit.

- Flowering: Small, fragrant white blossoms appear, lasting only a few days.

- Cherry Development: Green cherries appear, gradually turning yellow, then red when ripe.

- Harvesting: Ripe cherries are picked, typically 6-8 months after flowering.

💡 Did you know?

In regions near the equator with consistent rainfall, coffee plants may flower and produce cherries year-round, allowing for multiple harvests.

Harvesting: The First Critical Step

The journey from tree to cup begins with harvesting. This step is crucial, as the ripeness of the coffee cherry directly impacts flavor. There are two main harvesting methods:

- Selective Picking: This labor-intensive method involves hand-picking only the ripest cherries. It’s more common for specialty coffees and results in higher-quality beans.

- Strip Picking: All cherries on a branch are harvested at once, regardless of ripeness. This method is faster but can lead to more variation in bean quality.

Selective picking is labor-intensive and requires skilled workers

💡 Fun Fact

Coffee cherries do not ripen simultaneously, pickers must return to the same trees multiple times throughout the harvesting season to ensure that only the best cherries are collected. This meticulous process not only enhances the quality of the coffee but also provides a unique and rewarding experience for those involved in the harvest.

Strip picking has gained popularity in recent decades due to advancements in machinery and the economic pressures faced by coffee producers

Processing Methods in the Coffee Processing Industry: Crafting Flavor Profiles

Now, we enter the heart of coffee processing. The method chosen significantly influences the final taste of your brew. Let’s explore the three main processing techniques:

Dry Process in the Coffee Processing Industry (Natural Process)

The dry process, a method called natural processing, is the oldest method of coffee processing, relying on nature’s elements to transform cherries into beans.

- Drying Techniques: Freshly picked cherries are spread in thin layers on patios or raised beds, basking in the sun for 2-4 weeks.

- Constant Care: Workers diligently rake the cherries throughout the day, ensuring even drying and preventing mold growth.

- Moisture Monitoring: Cherries are dried until they reach a precise moisture content of 11-12%, a critical factor in preserving flavor and preventing spoilage.

- Hulling and Polishing: Once dried, the husks are removed using specialized machinery, revealing the precious beans inside.

Natural processed coffees often have a heavier body, lower acidity, and more complex fruit notes. This method is common in regions with limited water resources, like Ethiopia.

Dry processed coffees tend to have a heavier body and more pronounced, fruity flavors

Wet Process in the Coffee Processing Industry (Washed Process)

Wet-processed coffee, commonly known as washed process coffee, offers more control over the final flavor profile, making it a favorite among specialty coffee producers.

- Pulping: Freshly harvested cherries are fed into pulping machines, which strip away the skin and most of the fruit pulp.

- Fermentation Magic: The beans, still coated in a sticky layer called mucilage, are fermented in tanks or water channels for 12-36 hours. This crucial step develops complex flavors and removes the remaining fruit residue.

- Washing and Drying: After fermentation, the beans are thoroughly washed and then dried using methods similar to the dry process.

This method allows the true characteristics of the bean to shine through, resulting in coffees with higher acidity and clarity of flavor.

Wet processing yields high-quality coffee, yet requires significant water resources

Honey Process in the Coffee Processing Industry (Pulped Natural Process)

This innovative method combines elements of both dry and wet processing, creating unique flavor profiles that are taking the coffee world by storm.

- Partial Pulping: Cherries are pulped to remove the skin and most of the pulp, but unlike the wet process, some mucilage is left on the beans.

- Controlled Drying: The partially pulped beans are dried with their remaining mucilage intact, typically on patios or raised beds.

- Flavor Development: This process results in a beautifully balanced cup, showcasing both the bright acidity of washed coffees and the sweet, full-bodied notes of natural processed beans.

Honey processed coffees often have a sweetness reminiscent of honey (hence the name), with a balance of acidity and body.

Honey process coffee is a unique method of coffee processing that lies between the washed and natural methods

Drying: A Delicate Balance

Regardless of the processing method, proper drying is crucial. Beans must reach a moisture content of about 11-12% to be stable for storage and transport. This step requires careful monitoring – too much moisture can lead to mold, while over-drying can make beans brittle and affect flavor.

To achieve optimal moisture content, beans are spread on drying tables, also known as raised beds, allowing for improved air circulation during the drying process.

Many producers are now investing in solar dryers or mechanical dryers to have more control over this critical phase. Industry experts generally agree that careful attention to the drying process can significantly impact a coffee’s flavor profile and overall quality score, which in turn affects its market value.

Sorting and Grading: Ensuring Quality

Once dried, beans undergo rigorous sorting and grading. This involves:

- Removing defective beans

- Sorting by size and density

- Grading based on quality standards

Advanced technology like color sorters and density tables have revolutionized this process, but many specialty coffee producers still rely on skilled workers for hand-sorting to ensure the highest quality.

Roasting: Where Flavors Come Alive

After processing and sorting, coffee beans undergo perhaps the most magical step of all: roasting. This is where the true character of the coffee emerges, transforming the green beans into the aromatic brown beans we all recognize.

Roasting is essentially a carefully controlled process of heating coffee beans. During this process, several key changes occur:

- Maillard Reaction: This chemical reaction between amino acids and sugars creates hundreds of different flavor compounds and contributes to the brown color of roasted coffee.

- Caramelization: As temperatures rise, sugars in the bean begin to caramelize, adding sweetness and depth to the flavor profile.

- Internal Pressure Build-up: Moisture and carbon dioxide inside the bean create pressure, causing the bean to expand and eventually crack, known as the “first crack” and “second crack”.

- Oil Migration: At higher temperatures, oils inside the bean migrate to the surface, giving dark roasts their shiny appearance.

Coffee Roasting

The Human Element: Skill and Tradition

Modern roasting combines artisanal skill with cutting-edge technology:

- Drum Roasters: Traditional method where beans tumble in a rotating drum. Allows for even heat distribution and flavor development.

- Hot-Air Roasters: Uses convection heating for a faster, more consistent roast. Popular for large-scale operations.

- Profile Roasting: Advanced software allows roasters to create and replicate specific roast profiles, ensuring consistency across batches.

Despite technological advances, the human element remains crucial in coffee processing. Experienced producers, often with generations of knowledge passed down through families, rely on their deep understanding of their land and crops to make critical decisions throughout the process. This blend of traditional wisdom and modern technology is what often results in truly exceptional coffee.

Despite technological advances, the human element remains crucial in coffee processing

From Bean to Cup: The Final Steps

After roasting, beans are typically allowed to “rest” for 12-24 hours, allowing CO2 to escape and flavors to stabilize. They’re then packaged – often in bags with one-way valves to allow continued CO2 release – and shipped to cafes, stores, or directly to consumers.

- Degassing: Freshly roasted coffee releases carbon dioxide, requiring a resting period before packaging to prevent bag ruptures.

- Packaging Innovation: Modern coffee bags often feature one-way valves, allowing CO2 to escape while keeping oxygen out. Some producers even use nitrogen flushing to extend shelf life.

- Storage Best Practices: To preserve quality, store coffee in a cool, dry place away from direct sunlight and strong odors. While refrigeration can extend shelf life, it may also introduce unwanted moisture.

Environmental Considerations and Sustainable Practices

As the coffee industry grapples with climate change and environmental concerns, processing methods and cultivation practices are evolving to be more sustainable.

- Water Conservation: Water conservation is a major focus, especially in regions facing scarcity. The Coffee Research Institute reports that washed processing can use up to 130 liters of water per kilogram of coffee. In response, many producers are implementing water recycling systems or opting for less water-intensive methods like natural processing.

- Shade-Grown Coffee: An increasing number of farmers are adopting shade-grown coffee practices. This method involves growing coffee plants under a canopy of trees, which offers several benefits:

- Preserves biodiversity by providing habitats for birds and other wildlife

- Reduces the need for chemical fertilizers as fallen leaves enrich the soil

- Protects coffee plants from extreme weather conditions

- Carbon Sequestration: Coffee plants, especially when grown using shade-grown methods, can act as significant carbon sinks. A study by the Smithsonian Migratory Bird Center found that a hectare of shade-grown coffee can sequester up to 250 tons of carbon dioxide, contributing to climate change mitigation.

- Byproduct Repurposing: The byproducts of coffee processing, such as pulp and wastewater, are being repurposed in innovative ways:

- Composting for fertilizer

- Biogas production

- Creating cascara products

These initiatives not only reduce waste but also create additional revenue streams for farmers, promoting economic sustainability alongside environmental benefits.

Ready to improve the production of instant coffee for your company? Get in touch with our experts right now!

Conclusion: A Cup Full of Passion and Expertise

From the careful selection of ripe cherries to the final packaging of roasted beans, every step in coffee processing plays a crucial role in crafting the perfect cup. As we’ve seen, it’s a complex interplay of science, skill, artistry, and increasingly, cutting-edge technology. The coffee processing industry stands at an exciting crossroads of tradition and innovation. While time-honored methods continue to produce exceptional coffees, new technologies are opening up possibilities for improved quality, consistency, and sustainability at scale.

The next time you sip your morning coffee, take a moment to appreciate the journey it’s been on. Each cup represents not just beans, but a global industry of dedicated professionals working to bring out the best in every harvest, supported by increasingly sophisticated tools and techniques.