Industrial wood chip burners are gaining traction as businesses look for renewable and cost-effective solutions to meet their heating and processing needs.

They’re not just eco-friendly – they’re wallet-friendly too.

As companies hunt for sustainable ways to power up, biomass energy is stepping into the spotlight.

And wood chip burners? They’re leading the pack.

We’re diving deep into the world of industrial wood chip burners.

We’ll break down the top-brand industrial wood chip burners, comparing them side by side, looking at:

- How efficient they are

- Their automation capabilities

- How well they scale up

- Their green credentials

By the end, you’ll know exactly which industrial wood chip burner to choose for your business.

Factors for Evaluating Industrial Wood Chip Burners

To evaluate which industrial wood chip burner is best, it’s essential to consider several key factors:

- Heat Output and Efficiency: How much energy can the system generate, and how efficiently does it convert wood chips into heat?

- Automation and Control: Does the burner offer features like real-time monitoring, automatic adjustments, and safety mechanisms?

- Versatility: Can the burner handle varying types and qualities of wood chips, including those with higher moisture content?

- Environmental Impact: How well does the system minimize emissions and improve sustainability?

- Durability and Maintenance: Is the system designed for longevity with minimal maintenance requirements?

The Best Industrial Wood Chip Burner

Comparison Table Of The Top Brand Industrial Wood Chip Burners

| Feature | Vina Nha Trang Industrial Wood Chip Burner | Hargassner Eco HK | Fröling T4 | Froling TX |

|---|---|---|---|---|

| Heat Capacity | 6,000 – 10,000 kW | Up to 330 kW | Medium-scale | Medium-scale |

| Fuel Moisture Handling | Up to 40% moisture | Up to 30% moisture | Up to 30% moisture | Up to 30% moisture |

| Control System | Automated, PLC control with real-time adjustments | Automated, basic self-cleaning | Automated, with auto-ignition | Automated, efficient with limited real-time adjustments |

| Sustainability | Fluidized bed grate, dust filtration | Low emissions, compact design | Low emissions, eco-friendly | High energy efficiency, low emissions |

| Safety Features | Automatic temperature control, slag collection, smoke release | Basic safety mechanisms | Basic fire control, emissions control | Fire control, spark detection |

| Durability and Maintenance | High durability, minimal maintenance | Low maintenance, smaller scale | Requires regular maintenance for ash cleaning | Easy to maintain for smaller setups |

| Best For | Large-scale industrial operations | Small to medium operations | Small to medium operations | Medium operations, compact spaces |

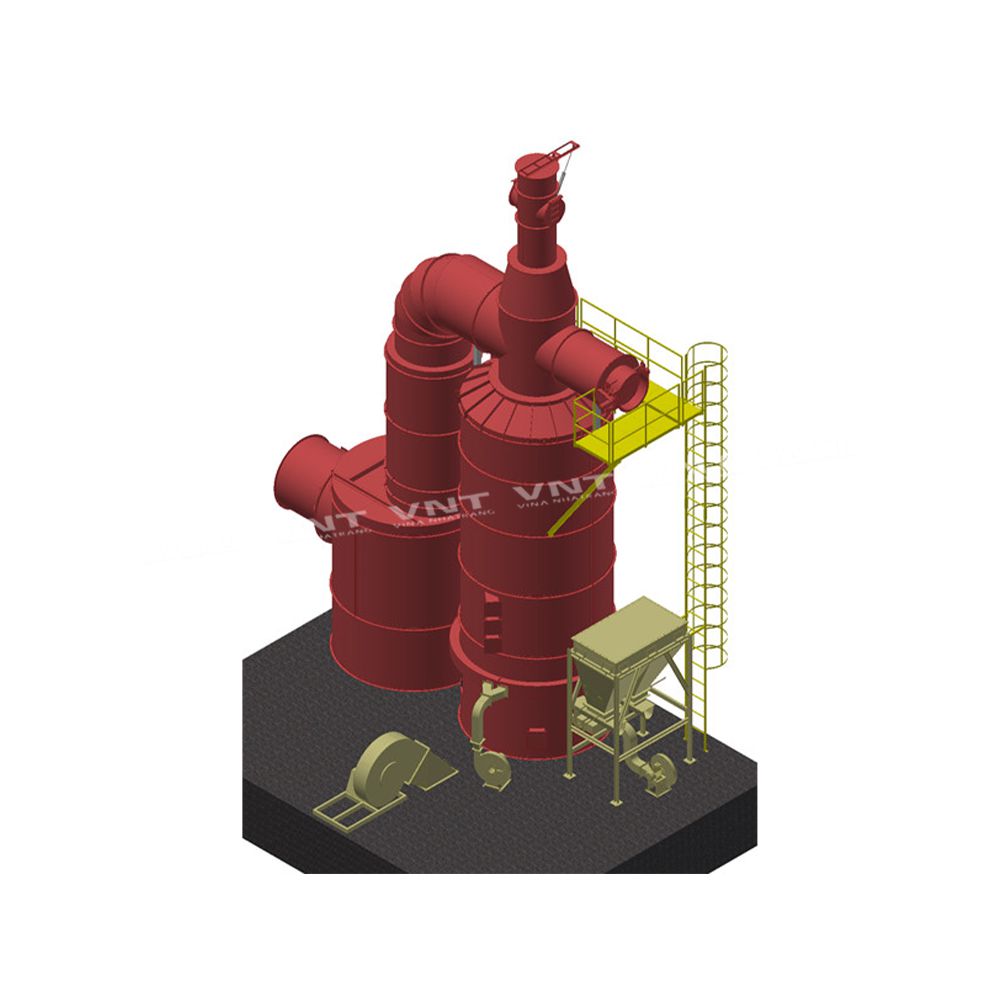

1. Vina Nha Trang Industrial Wood Chip Burner

Vina Nha Trang has developed an industrial wood chip burner that stands out for its high efficiency, advanced automation, and versatile fuel handling. This burner offers a heat capacity ranging from 6,000 to 10,000 kW, making it ideal for large-scale industrial applications. One of its unique features is the ability to process wood chips with moisture levels up to 40%, ensuring that the burner can handle a wide variety of fuel types.

The Vina Nha Trang system uses a fluidized bed grate for combustion, which promotes thorough fuel burning, maximizing heat generation while minimizing waste. Additionally, its PLC-controlled automation allows for precise real-time monitoring of both temperature and humidity levels within the burner. This feature is critical in industries where fuel conditions vary, as it enables operators to adjust the burner’s operation dynamically based on the material’s moisture content.

Key Features:

- Heat capacity: 6,000-10,000 kW.

- Control: Automated through a PLC system.

- Combustion Material: Wood chips, including those with up to 40% moisture.

- Real-time monitoring: Integrated humidity sensors for automatic adjustments.

- Safety: Features automatic temperature control, slag collection, and a safety valve for smoke release

Vina Nha Trang’s system also boasts long-term cost savings due to its durability and minimal maintenance needs. Its dust filtration system ensures cleaner emissions, further contributing to its eco-friendly appeal. For industries where sustainability and reliability are paramount, this system is a robust choice.

2. Hargassner Eco HK Wood Chip Boiler

Hargassner is a reputable name in biomass technology, offering highly efficient wood chip boilers. Their Eco HK model, known for its compact design, provides heat outputs up to 330 kW, making it ideal for smaller operations. However, compared to Vina Nha Trang’s high-capacity burner, the Eco HK model falls short in terms of scalability.

Hargassner boilers also feature automatic feeding systems and self-cleaning functions, reducing maintenance requirements. However, they often struggle with high-moisture fuels, as their optimal performance is achieved with wood chips that have a moisture content below 30%, which limits their versatility.

Pros:

- Suitable for smaller, medium-sized operations.

- Advanced self-cleaning mechanisms.

- Environmentally friendly with low emissions.

Cons:

- Lower heat capacity (up to 330 kW).

- Limited capability with higher moisture wood chips.

3. Fröling T4 Wood Chip Boiler

Fröling’s T4 wood chip boiler is one of the top models in Europe, known for its environmental performance and low emissions. This model is highly automated, offering features like automatic ignition and ash disposal. While it’s ideal for small to medium industrial setups, the T4 does not match the heat capacity or real-time monitoring features seen in Vina Nha Trang’s burner. Moreover, the Fröling T4 performs best when the moisture content of the fuel is below 30%, limiting its versatility compared to Vina Nha Trang’s system.

Pros:

- Strong environmental performance with low emissions.

- Automated ignition and ash disposal.

Cons:

- Lower heat output compared to Vina Nha Trang’s burner.

- Limited handling of high-moisture wood chips.

4. Froling TX Wood Chip Boiler

The Froling TX series is another highly regarded model, offering high energy efficiency and advanced automation. The TX series is compact and can be used in spaces where a larger burner might not fit. However, similar to Fröling’s other models, it is designed for medium-scale operations and doesn’t have the capacity to support large industrial setups. Its automation, while sophisticated, does not offer the real-time precision and moisture control that the Vina Nha Trang system provides.

Pros:

- High efficiency with reduced emissions.

- Compact design for smaller spaces.

Cons:

- Limited scalability.

- Lacks the moisture control and automation capabilities of larger systems.

Why Vina Nha Trang Leads the Market

Vina Nha Trang’s industrial wood chip burner not only matches but exceeds the performance of its competitors in several critical areas:

- High-Capacity Heat Output: While competitors like Hargassner and Fröling are well-suited for smaller applications, Vina Nha Trang’s burner is designed for large-scale industrial use, offering a heat capacity of up to 10,000 kW, significantly more than others in the market.

- Versatile Fuel Handling: Vina Nha Trang’s burner can handle wood chips with up to 40% moisture, while other systems, such as Hargassner and Fröling, struggle with anything above 30%, limiting their flexibility in fuel selection.

- Advanced Automation: The PLC-controlled system in Vina Nha Trang’s burner offers real-time monitoring and adjustment of humidity and temperature, a feature that both improves efficiency and reduces operational costs. Other systems have automated controls, but they lack the real-time precision offered by Vina Nha Trang.

- Sustainability and Maintenance: With integrated safety features and a dust filtration system, Vina Nha Trang’s burner minimizes emissions and is easier to maintain than many other burners, which require more manual intervention to manage waste and maintain performance.

Conclusion

While several manufacturers offer reliable and efficient industrial wood chip burners, Vina Nha Trang clearly stands out as the best option for large-scale, industrial applications. Its high-capacity output, ability to handle high-moisture fuels, and advanced automation make it a top contender in the market. When compared with leading brands like Hargassner, Fröling, and Froling, Vina Nha Trang’s burner offers superior performance, particularly for businesses seeking scalability, sustainability, and long-term efficiency.

FAQ

Q: What is the maximum fuel moisture content the Vina Nha Trang burner can handle?

A: The Vina Nha Trang burner can process wood chips with a moisture content of up to 40%, making it more versatile compared to other systems that typically handle only up to 30%.

Q: How does the Vina Nha Trang burner reduce emissions?

A: The system includes a dust filtration system, along with optimized combustion using a fluidized bed grate. These features reduce the amount of dust and emissions released into the environment, promoting cleaner and more sustainable operations.

Q: Is the Vina Nha Trang burner suitable for small operations?

A: The Vina Nha Trang burner is designed for large-scale industrial applications, with a heat capacity of up to 10,000 kW. Smaller operations may find systems like the Hargassner or Fröling T4 more appropriate due to their lower heat output and compact designs.

Q: How does the automation in Vina Nha Trang’s system work?

A: The burner uses a PLC-controlled system for real-time monitoring and adjustments. This allows operators to automatically control the fan speed, combustion material feed, and burner temperature based on the fuel’s humidity and operational needs.

Q: What makes Vina Nha Trang’s burner stand out from competitors?

A: Vina Nha Trang’s burner excels in fuel flexibility, high heat output, and advanced real-time controls. It is designed to handle a broader range of wood chip qualities, including high-moisture fuels, which gives it a significant edge over competitors.