Coffee is a universal beverage enjoyed by millions worldwide, and at the heart of its flavor lies the delicate roasting process. The coffee plant roaster is vital in transforming raw green beans into aromatic, flavorful roasted coffee. This article explores the intricate details of the coffee roasting process, factors influencing its outcomes, and the tools and techniques involved, ensuring precision and consistency in quality.

Introduction

The art and science of coffee roasting aim to produce beans that deliver rich flavor and aroma. The coffee plant roaster is the machinery that ensures uniform roasting while enhancing the chemical and physical characteristics of the beans. Achieving consistent roasted bean color is critical for maintaining flavor quality across batches. This is why every detail of the roasting process, from preheating to final cooling, is meticulously managed in industrial setups.

In modern coffee production, the coffee plant roaster focuses on roasting and monitors the temperature, moisture levels, and weight consistency to ensure the best output. This guide delves into how the coffee plant roaster achieves this and how external factors like bean moisture and equipment wear affect results.

The Coffee Plant and Beans

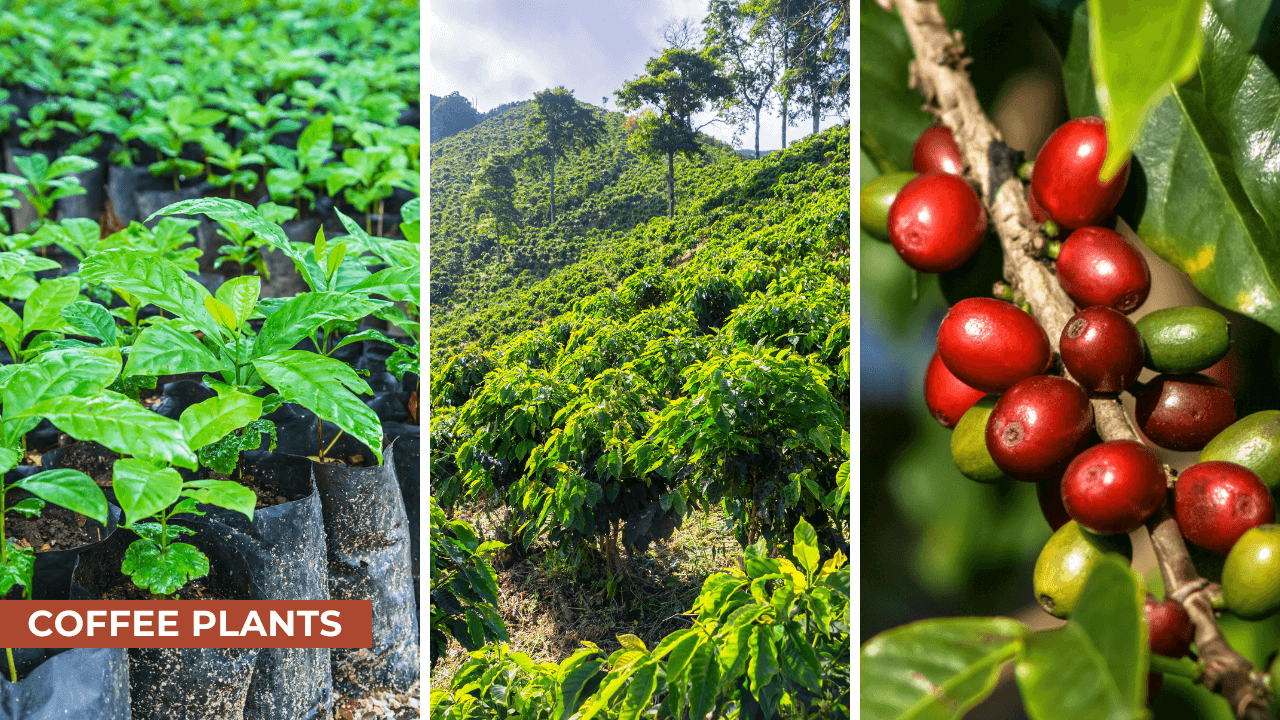

The journey of coffee begins with the coffee plant, a remarkable shrub native to tropical climates and known for its fragrant blossoms and vibrant berries. The transformation from these berries to the roasted beans we recognize is a meticulous process, and understanding the coffee plant and its beans is essential to appreciating the role of the coffee plant roaster in creating exceptional coffee.

Characteristics of the Coffee Plant

The coffee plant belongs to the family Rubiaceae and the genus Coffea. It is typically cultivated in regions between the Tropics of Cancer and Capricorn, where the climate provides the warmth and moisture necessary for optimal growth.

- Structure: The plant features one or more central trunks, from which primary branches extend. The leaves, which are glossy, deep green, and oval-shaped with a wavy edge, grow in opposite pairs. These leaves are visually similar to laurel leaves, contributing to the plant’s aesthetic.

- Flowers: Clusters of white flowers adorn the plant, with each flower measuring approximately 2 centimeters in size. These blooms emit a sweet fragrance, signaling the beginning of the fruiting process.

- Fruit (Drupe or Berry): The plant produces small, round berries that mature to a bright red color when ripe. Each berry contains two seeds, or beans, which are the primary component used in coffee production. The outer layers of the berry, including a thick pulpy skin and jelly-like pulp, are discarded during processing.

Types of Coffee Beans

Of the many species in the Coffea genus, only two are cultivated on a large scale for commercial purposes: Coffea Arabica and Coffea Canephora (commonly known as Robusta). These species differ significantly in flavor profile, growing conditions, and economic significance.

- Arabica:

- Represents approximately 70% of global coffee production.

- Known for its mild and nuanced flavors, often with a sweeter, fruitier profile.

- Grows at higher altitudes with cooler temperatures, making it more sensitive to environmental changes.

- Robusta:

- More robust and resistant to pests and diseases.

- Often used in blends to add body and a stronger, more bitter flavor.

- Grows at lower altitudes and can tolerate warmer climates.

The balance of these two types in a blend directly impacts the coffee plant roaster’s job, as different beans may require unique roasting profiles.

Pre-Roasting Preparations

Before coffee beans are ready for the roaster, they undergo several crucial steps to ensure they are clean, consistent, and suited to the desired flavor profile.

- Transportation and Quality Checks:

- Green beans are transported from their country of origin, usually in bulk containers.

- Upon arrival, the beans are inspected for quality and consistency, ensuring that they meet production standards.

- Blending:

- The blending process combines beans of varying taste profiles to achieve a balanced flavor. For example:

- Bitter and acidic flavors are balanced for a well-rounded cup.

- Beans with distinctive aromas are selected to enhance the sensory experience.

- Blending may occur before or after roasting, depending on the desired outcome. A well-executed blend ensures that any natural variations in bean flavor are mitigated, providing a consistent taste.

- The blending process combines beans of varying taste profiles to achieve a balanced flavor. For example:

Green Beans and Their Role in Roasting

Green coffee beans, though unassuming in appearance, are the raw material that the coffee plant roaster transforms into the flavorful roasted beans we enjoy. These beans are small, dense, and greenish-blue in color before roasting.

- Moisture Content: The beans contain about 10-12% moisture, which plays a significant role during roasting. Variations in this moisture content influence the energy required for roasting and the overall flavor profile.

- Chemical Composition: Green beans are rich in carbohydrates, proteins, and oils. During roasting, these compounds undergo chemical transformations that define the final taste and aroma.

The Importance of the Coffee Plant Roaster

The coffee plant roaster must account for all these variables when preparing green beans for roasting. Factors such as bean type, moisture level, and blend composition affect how the beans will respond to heat and ultimately influence the roasted coffee’s flavor. Proper handling of green beans ensures that the roaster can produce consistent results batch after batch.

By understanding the coffee plant and beans, we can appreciate the precision required in every stage of coffee production. The coffee plant roaster bridges the gap between these raw materials and the aromatic, flavorful coffee enjoyed worldwide.

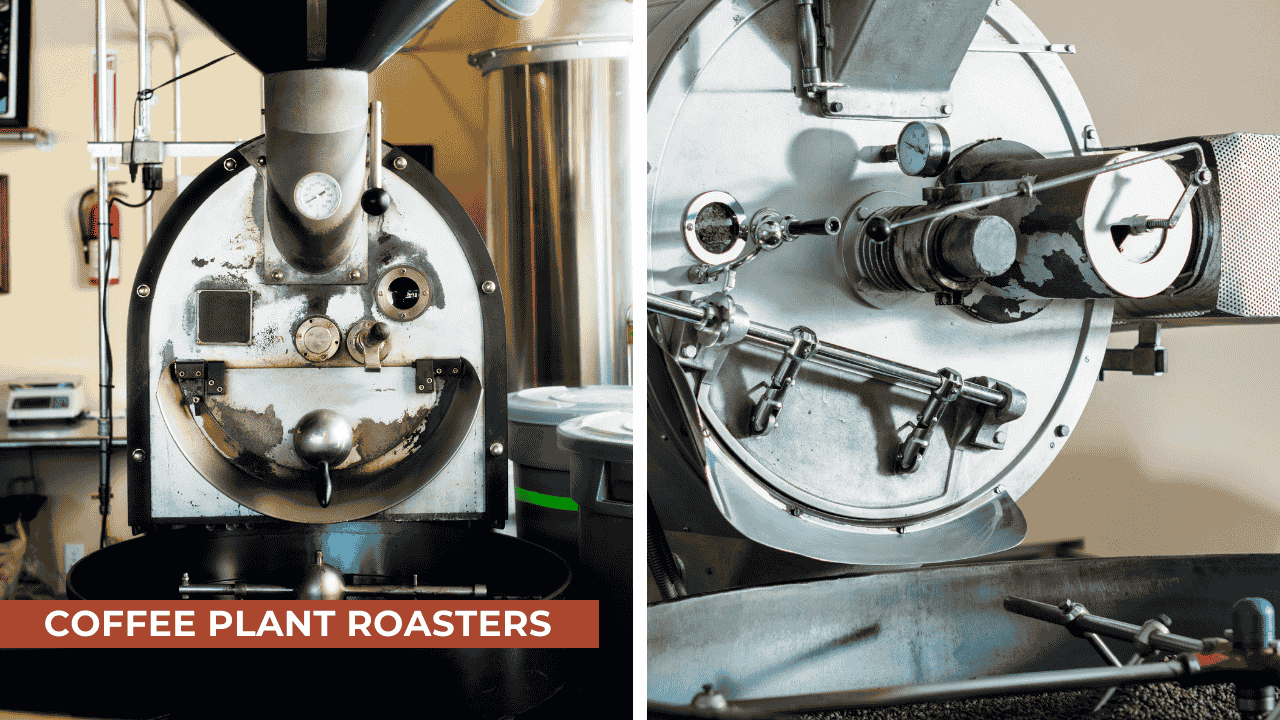

Coffee Roasters

The coffee plant roaster is an indispensable tool in coffee production, serving as the centerpiece of the roasting process. From small-scale experimental setups to large industrial machines, coffee roasters are designed to ensure precision, consistency, and efficiency. This section explores the types, components, and functionalities of coffee plant roasters and the critical differences between industrial and pilot roasters.

Types of Coffee Plant Roasters

The coffee plant roaster comes in two primary types, each tailored to specific needs in the production and development of roasted coffee.

- Industrial Roasters:

- Designed for large-scale production, these machines can handle batches of up to 700 kg.

- Primarily used in commercial operations to produce consistent, high-quality roasted beans at scale.

- Feature advanced systems for temperature and airflow control to maintain uniformity across large quantities.

- Pilot Roasters:

- Smaller, experimental roasters with a typical capacity of around 10 kg.

- Used for testing and refining roasting techniques before scaling up to industrial production.

- Provide precise control over roasting variables, making them ideal for research and development.

Both types of coffee plant roasters are essential in modern coffee production, with industrial roasters focusing on efficiency and volume, while pilot roasters emphasize experimentation and fine-tuning.

Components of Coffee Plant Roasters

The coffee plant roaster is a sophisticated machine composed of several components, each serving a specific role in the roasting process:

- Heating System:

- A furnace generates heat, which is transferred to the beans through circulating air.

- Ensures consistent temperature control, which is critical for achieving the desired roast level.

- Stirrer:

- A mechanical stirrer keeps the beans in constant motion to ensure even exposure to heat.

- Prevents beans from burning or under-roasting.

- Fan and Chimney:

- Extracts gases and chaff (the thin skin of the beans) released during roasting.

- Helps maintain a clean and safe roasting environment.

- Afterburner:

- Burns off the gases extracted during roasting, reducing odors and emissions.

- Ensures compliance with environmental standards.

- Cooling System:

- Immediately after roasting, beans are cooled using water sprays or a cold airflow.

- Rapid cooling halts the roasting process to lock in the desired flavor and aroma.

These components work together to ensure that the coffee plant roaster produces beans with a uniform roast, minimizing the risk of defects.

Explore more: Choosing the Right Coffee Roaster Equipment for Your Business

The Coffee Roasting Process

The roasting process managed by the coffee plant roaster involves several key stages:

- Preheating:

- The roaster is preheated to a specific starting temperature, ensuring the beans roast evenly.

- Roasting:

- Heated air is circulated throughout the chamber, with the stirrer ensuring uniform heat distribution.

- Cooling:

- Beans are rapidly cooled using water or air to prevent over-roasting.

- Storage:

- Roasted beans are stored in containers, allowing them to degas and stabilize.

These steps are optimized in industrial roasters for large-scale production, while pilot roasters allow for fine-tuning of variables during testing.

Industrial vs. Pilot Roasters

Despite their shared purpose, industrial and pilot coffee plant roasters differ in several ways that affect their functionality and applications:

| Feature | Industrial Roasters | Pilot Roasters |

|---|---|---|

| Batch Size | Up to 700 kg, with batch weight variability of 30 kg. | Around 10 kg, with precise weight control (up to 0.5 g accuracy). |

| Airflow | Use recycled roast gases for efficiency. | Use fresh air, ensuring control over external variables. |

| Thermocouples | Thick thermocouples to withstand wear; slower response times. | Fine thermocouples for faster and more precise temperature readings. |

| Dependency Between Batches | Independent due to preheating between batches. | Dependent as the starting temperature is influenced by the previous batch. |

These distinctions highlight how the coffee plant roaster adapts to varying scales of operation, with industrial models prioritizing efficiency and pilot models offering precision for experimentation.

Environmental Considerations

Modern coffee plant roasters incorporate features to minimize environmental impact:

- Afterburners reduce emissions by burning off gases released during roasting.

- Proper handling of chaff ensures waste is managed efficiently.

- Recycling of roast gases in industrial roasters reduces energy consumption.

These advancements make the coffee plant roaster an essential tool not only for producing quality coffee but also for maintaining environmental responsibility.

The Role of Coffee Plant Roasters in Quality Control

The coffee plant roaster ensures that every batch of beans meets strict quality standards. From achieving consistent color to optimizing flavor profiles, the roaster’s precise control over heat, airflow, and cooling guarantees that the roasted coffee matches the desired specifications. Furthermore, the coffee plant roaster accommodates the unique characteristics of different bean types and blends, making it a versatile and indispensable part of coffee production.

In summary, the coffee plant roaster is the cornerstone of coffee production, responsible for turning green beans into the roasted coffee we enjoy. With their advanced design, industrial and pilot roasters cater to the needs of both large-scale production and precise experimentation, ensuring that every batch meets the highest standards of quality.

The Roasting Process

Factors Influencing Roast Quality

The quality of roasted coffee depends on a multitude of factors, both inherent to the beans and external to the roasting process. While the coffee plant roaster provides advanced controls to mitigate inconsistencies, the interplay of these factors requires careful management to ensure consistent flavor, aroma, and appearance. Below, we examine the primary variables that influence roast quality.

Bean Moisture Content

Moisture content is a critical factor influencing the roasting process. Green coffee beans typically contain 10–12% moisture, though this can vary based on factors like origin, processing methods, and storage conditions.

- Impact on Roasting:

- Beans with higher moisture require more energy to evaporate the water, prolonging the roasting process.

- This extended roasting can lead to uneven development, as some beans may begin caramelizing while others are still drying.

- Moisture content also affects gas release during roasting, impacting the texture and aroma.

- Control Measures:

- The coffee plant roaster compensates for moisture variability by adjusting roast duration and temperature.

- Proper storage of green beans in a stable environment minimizes moisture fluctuations.

Roast Temperature

Temperature is one of the most influential factors managed by the coffee plant roaster. Even minor deviations can significantly alter the flavor, aroma, and appearance of roasted coffee.

- Initial Temperature:

- Preheating the roaster ensures consistent conditions for all batches, reducing variability.

- The starting temperature is particularly important in industrial roasters, where batches are independent.

- Final Temperature:

- Determines the roast level and directly influences taste:

- Higher temperatures produce darker roasts with increased bitterness and reduced acidity.

- Lower temperatures preserve the beans’ natural acidity and fruity flavors.

- The coffee plant roaster must precisely terminate the process at the desired final temperature to avoid over-roasting.

- Determines the roast level and directly influences taste:

- Exothermic Reaction:

- At temperatures above 200°C, the roasting process shifts from endothermic (absorbing heat) to exothermic (releasing heat). If not carefully managed, this reaction can cause rapid overheating and flavor degradation.

Batch Weight

The weight of each batch plays a subtle yet important role in roast quality. Industrial coffee plant roasters handle batch weights of up to 700 kg, with typical variances of around 30 kg. While pilot roasters operate at smaller scales, even minor weight inconsistencies can affect roasting outcomes.

- Impact on Roasting:

- Larger batches require more heat energy, and uneven distribution can lead to under-roasted or over-roasted beans.

- Variability in batch weight influences the time-temperature curve, altering flavor development.

- Control Measures:

- The coffee plant roaster’s automated systems regulate heat distribution to account for weight differences.

- Manual weighing of pilot roaster batches achieves high precision, ensuring consistency.

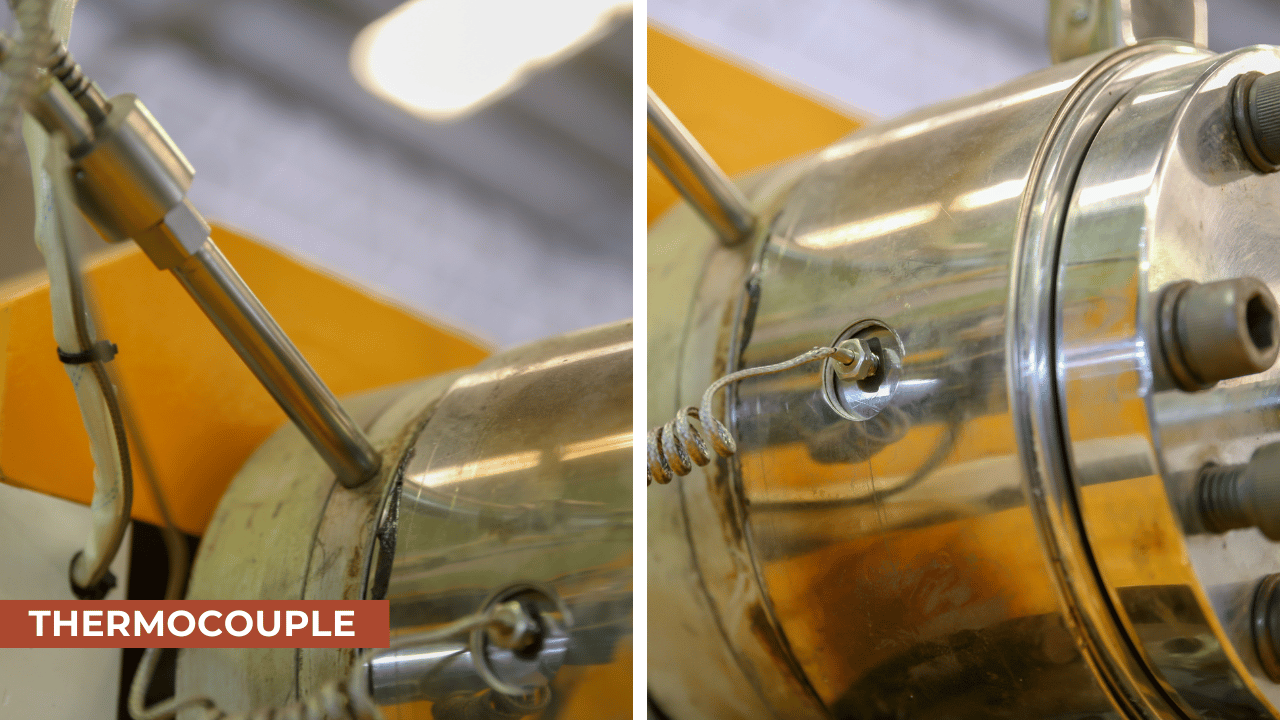

Equipment Wear

As with any industrial machinery, wear and tear on components of the coffee plant roaster can affect performance over time. Thermocouples, which measure temperature during roasting, are particularly susceptible.

- Thermocouple Wear:

- Prolonged use causes thermocouples to become less accurate, introducing deviations in temperature readings.

- This wear necessitates adjustments to final temperature settings to maintain consistency.

- Impact on Roast Quality:

- Inaccurate temperature measurements can result in over- or under-roasted beans, leading to off-flavors or inconsistencies in batch color.

- The slower response time of worn thermocouples may prevent precise adjustments during the process.

- Maintenance Strategies:

- Regular calibration and replacement of thermocouples minimize the impact of wear.

- Exploring alternative temperature measurement methods, such as monitoring roast gas temperatures, could offer greater reliability.

Airflow

Airflow within the coffee plant roaster is critical for achieving uniform roasting. It removes gases, chaff, and other byproducts while maintaining consistent heat distribution.

- Air Type:

- Industrial roasters often recycle roast gases, reducing energy consumption but introducing potential variability due to gas composition.

- Pilot roasters use fresh air for greater control over environmental factors.

- Impact on Beans:

- Insufficient airflow can cause uneven roasting, as beans may not receive consistent heat exposure.

- Proper airflow enhances chaff removal, preventing burnt particles from affecting flavor.

Bean Type and Blend Composition

Different bean varieties, such as Arabica and Robusta, require unique roasting approaches. Additionally, blends combine beans with varying density, moisture content, and flavor profiles.

- Arabica Beans:

- More delicate and sensitive to high temperatures, requiring a gentler roast profile.

- Tend to exhibit fruity and acidic notes that are easily lost with over-roasting.

- Robusta Beans:

- More robust and can tolerate higher roasting temperatures.

- Known for their earthy, bitter flavors, which develop best at darker roasts.

- Blends:

- The coffee plant roaster must consider the properties of each bean type in the blend, adjusting settings to balance flavor development.

Environmental Conditions

External factors, such as ambient temperature and humidity, can subtly influence the roasting process.

- Temperature:

- Cooler ambient temperatures may require longer preheating times.

- Hotter environments can accelerate the roasting process, potentially leading to over-roasting if not managed.

- Humidity:

- Higher humidity levels affect the beans’ moisture content, altering the energy needed for roasting.

- Compensation Measures:

- The coffee plant roaster’s automated controls adjust parameters to account for environmental fluctuations.

Maintaining Roast Quality

While the coffee plant roaster provides advanced tools to manage these factors, achieving consistent roast quality requires diligent monitoring and adjustment. Key practices include:

- Frequent Calibration: Ensures the roaster operates within desired specifications.

- Regular Maintenance: Prevents equipment wear from affecting performance.

- Continuous Monitoring: Tracks variables like temperature, airflow, and batch weight in real time.

The coffee plant roaster is a sophisticated machine designed to navigate the challenges posed by moisture content, temperature, batch weight, and other factors. By leveraging precise controls and regular maintenance, it ensures that every batch of roasted coffee meets the highest standards of quality, delivering consistent flavor and aroma to coffee lovers worldwide.

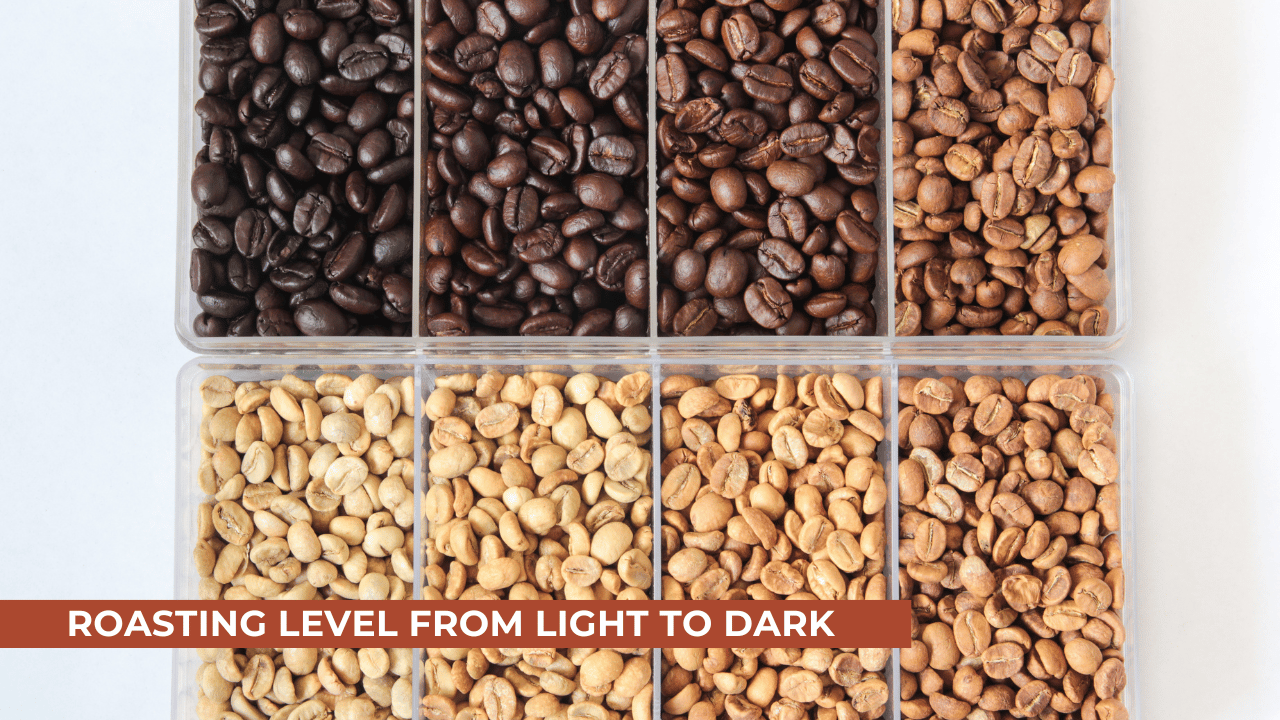

Color Control and Quality Assurance

Color is one of the most critical indicators of roasted coffee quality. It directly correlates with the flavor and aroma, serving as a visual cue for roast level consistency. The coffee plant roaster plays a central role in achieving precise color control, ensuring the roasted beans meet desired quality standards batch after batch. This section explores the importance of color, the challenges in maintaining consistency, and strategies for effective color control and quality assurance.

The Role of Color in Coffee Quality

Color serves as a tangible metric to evaluate the quality of roasted coffee:

- Indicator of Roast Level:

- Light, medium, or dark roasts exhibit distinct color ranges that correspond to flavor profiles. For example:

- Light roasts are pale brown, retaining higher acidity and subtle flavors.

- Medium roasts have a rich brown tone, balancing acidity, sweetness, and body.

- Dark roasts are deep brown to black, offering bold, smoky, and bitter notes.

- Consistent color ensures the desired flavor characteristics are achieved across batches.

- Light, medium, or dark roasts exhibit distinct color ranges that correspond to flavor profiles. For example:

- Consumer Expectations:

- Uniform color signifies quality and reliability, building consumer trust in the product.

- Variations in color can lead to perceptions of inconsistency or poor quality.

- Process Control:

- Measuring color provides feedback on the effectiveness of the roasting process, helping operators fine-tune the coffee plant roaster’s settings.

Challenges in Color Consistency

Achieving consistent color is complex due to several factors, despite the precision offered by the coffee plant roaster:

- Measurement Variability:

- Devices used to measure color can yield inconsistent results based on:

- Calibration differences.

- Environmental conditions such as lighting.

- The way the beans are ground and distributed for measurement.

- Devices used to measure color can yield inconsistent results based on:

- Bean Variability:

- Differences in moisture content, density, and size among green beans affect heat absorption and, consequently, color development.

- Equipment Wear:

- Thermocouples and other components of the coffee plant roaster may degrade over time, impacting temperature accuracy and roast uniformity.

- Human Error:

- Manual interventions during roasting, such as adjusting temperature settings, can introduce variability in color.

- External Disturbances:

- Fluctuations in ambient temperature, humidity, and airflow can subtly alter the roasting environment, influencing color outcomes.

Strategies for Color Control

To overcome these challenges, coffee producers rely on the coffee plant roaster’s advanced features and implement robust quality assurance practices:

- Standardized Measurement:

- Use the same color measurement device and protocol for all batches to minimize variability.

- Ensure beans are ground and distributed uniformly for accurate readings.

- Regular Calibration:

- Calibrate both the color measurement devices and the coffee plant roaster regularly to ensure consistent performance.

- Optimized Roaster Settings:

- Fine-tune temperature, airflow, and roast time based on the desired color profile.

- Preheat the roaster to maintain consistent initial conditions for every batch.

- Monitoring and Adjustments:

- Continuously monitor roast color during the process using automated systems.

- Make real-time adjustments to compensate for environmental or bean-related variability.

- Frequent Sampling:

- Measure color for multiple batches within a production cycle to detect deviations early.

- Increase sample sizes for more reliable averages, particularly in industrial-scale operations.

- Data Analysis:

- Collect and analyze color data from each batch to identify trends and improve process control.

- Use this data to predict and mitigate potential disturbances.

Quality Assurance in the Roasting Process

The coffee plant roaster contributes to quality assurance by ensuring precise control over all variables influencing color. However, additional measures are necessary to maintain high standards:

- Batch Testing:

- Conduct routine quality checks for each batch, including color measurement and sensory evaluation.

- Reject or reprocess batches that fall outside acceptable color ranges.

- Process Documentation:

- Maintain detailed records of roast settings, color measurements, and any adjustments made during production.

- Use these records for troubleshooting and improving future roasts.

- Operator Training:

- Train operators to recognize subtle variations in roast color and make informed adjustments.

- Emphasize the importance of adhering to standardized procedures.

- Maintenance of Equipment:

- Regularly service the coffee plant roaster to ensure that all components, especially thermocouples and heating elements, function optimally.

- Replace worn components promptly to prevent roast inconsistencies.

The Relationship Between Color and Flavor

While color is not the sole determinant of flavor, it provides a reliable indication of the roast level and associated taste profile:

- Lighter Colors: Indicate higher acidity and milder flavors, often preferred in specialty coffees.

- Darker Colors: Suggest bolder, more robust flavors with reduced acidity.

The coffee plant roaster must balance color and flavor development, ensuring that both align with the intended product profile.

The Coffee Plant Roaster’s Role in Maintaining Consistency

The coffee plant roaster is equipped with tools to address challenges in color control:

- Automated Controls: Regulate temperature and airflow for precise color development.

- Real-Time Monitoring: Provides feedback on roast progression, allowing operators to intervene if necessary.

- Scalability: Whether for pilot or industrial roasters, these machines ensure that processes are repeatable and consistent across varying batch sizes.

Conclusion

Color control is integral to coffee roasting, directly impacting flavor consistency, consumer satisfaction, and overall product quality. By leveraging the capabilities of the coffee plant roaster and adopting robust quality assurance measures, coffee producers can achieve uniform color and maintain high standards across every batch. This meticulous attention to detail ensures that each cup of coffee meets the expectations of even the most discerning consumers.

Conclusion

The coffee plant roaster is a sophisticated system essential to the production of high-quality coffee. By managing variables like temperature, moisture content, and batch weight, the roaster enables precise control over the roasting process, ensuring a consistent and flavorful product.

Several factors influence the roasting process, including the type of roaster, initial bean conditions, and equipment wear. Maintaining uniformity in color and flavor requires continuous monitoring and improvement in roasting practices.

Achieving excellence in coffee roasting demands a combination of skilled operation, robust technology, and thorough quality assurance. By focusing on these areas, the coffee plant roaster ensures that each batch meets the highest standards, satisfying coffee lovers worldwide.