The process of grinding coffee beans is a critical step that directly influences the flavor and quality of the final brew. Achieving uniformity in grind size is essential, as it affects how coffee grounds extract during brewing. Among the various grinding methods, burr coffee grinders are often considered the best due to their ability to create consistent grind sizes, making them ideal for specialty coffee enthusiasts.

In this comprehensive guide, we walk through the mechatronic design considerations and engineering challenges that go into creating an efficient burr coffee grinder. We will explore how a combination of mechanical and electronic systems can be optimized to deliver exceptional performance, focusing on uniformity, motor control, temperature management, and other key features.

Types of Burr Coffee Grinders

Conical Burr vs. Flat Burr

Burr coffee grinders are available in two main types: conical burr grinders and flat burr grinders. Both designs have distinct advantages and affect the grind uniformity and flavor extraction in different ways.

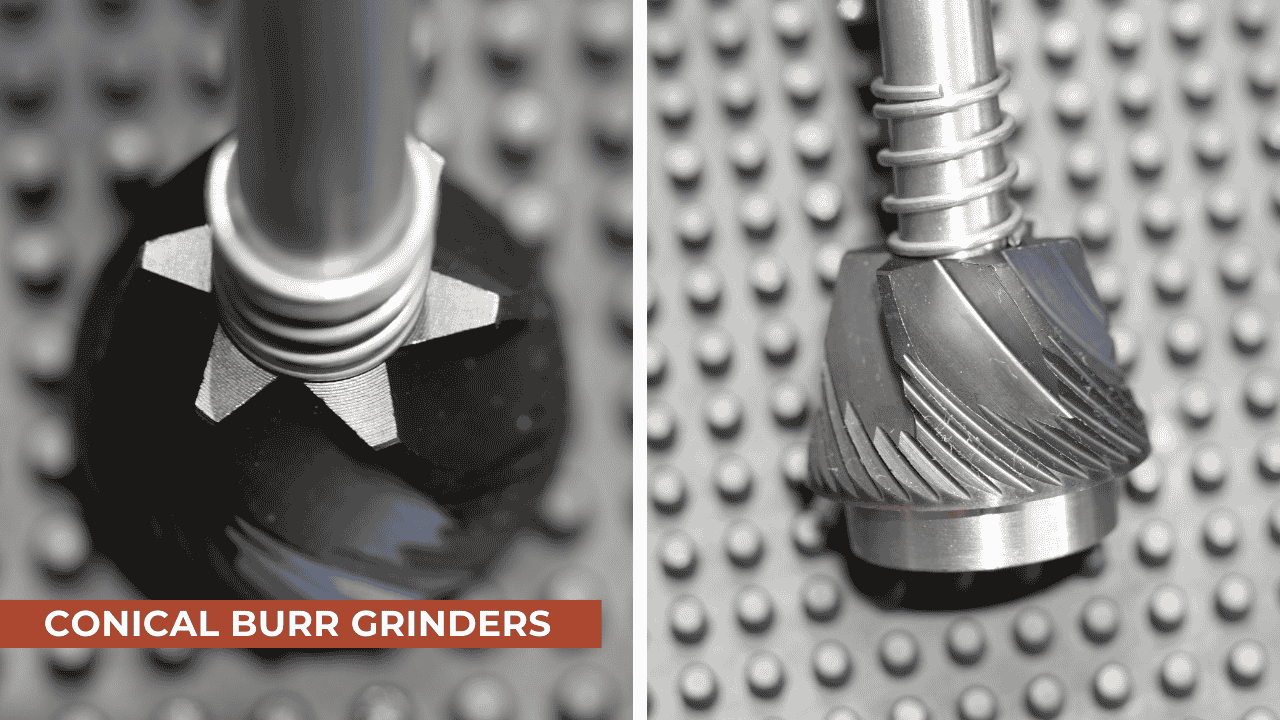

Conical Burr Grinders

Conical burr grinders feature two cone-shaped burrs, one of which remains stationary while the other rotates. This design uses gravity to help move the coffee beans through the grinding mechanism. Because of their shape, conical burr grinders can operate efficiently at lower speeds, which reduces heat generation. Lower heat is crucial for maintaining the natural flavors and aromas of the coffee, as excess heat can negatively impact the coffee’s profile.

Conical burr grinders feature two cone-shaped burrs, one of which remains stationary while the other rotates. This design uses gravity to help move the coffee beans through the grinding mechanism. Because of their shape, conical burr grinders can operate efficiently at lower speeds, which reduces heat generation. Lower heat is crucial for maintaining the natural flavors and aromas of the coffee, as excess heat can negatively impact the coffee’s profile.

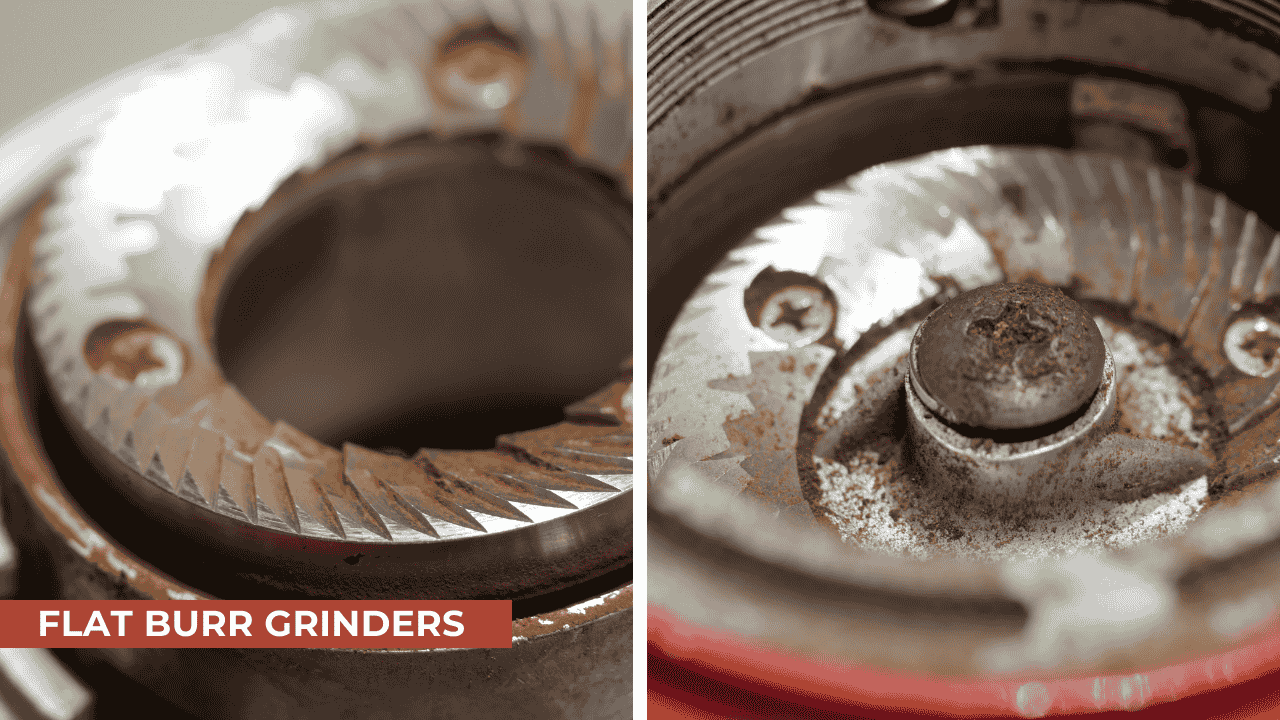

Flat Burr Grinders

Flat burr grinders consist of two flat, parallel burrs that grind the coffee beans horizontally. The beans are crushed as they pass between these burrs, and the distance between the burrs determines the grind size. Flat burr grinders generally produce more uniform grind sizes compared to conical burr grinders. However, they often require higher motor speeds, leading to greater heat production, which can compromise the flavor of the coffee.

Impact on Grind Uniformity and Flavor Extraction

Consistency in grind size is fundamental for balanced flavor extraction. Inconsistent particle sizes can result in over-extraction of smaller particles, leading to bitterness, and under-extraction of larger ones, causing sourness. Burr grinders excel in creating uniform grind sizes compared to blade grinders, which tend to produce uneven grounds.

A case study, “A Systems Engineering Design Process for Production Machines: Application to a Coffee Grinder” by Martínez Franco, Nicolás Antonio, highlights the significance of uniformity in grind size. Burr grinders, especially those with conical burrs, can achieve a uniformity coefficient as high as 3.8 for fine grinds, making them suitable for precision brewing methods.

Key Components of a Burr Coffee Grinder

Grinding Mechanism

At the heart of every burr grinder is its grinding mechanism. Burrs are typically made from ceramic or metal, and each material has a unique impact on grind uniformity and heat dissipation. Unlike blade grinders that chop beans irregularly, burr grinders crush and cut the beans between two abrasive surfaces. This method ensures a more consistent grind, with particle sizes ranging from 350 µm for fine grounds to 900 µm for coarse grounds, as specified by Colombian standards NTC 3534 and NTC 2441.

Impact of Burr Design

The design of the burrs plays a significant role in the grinder’s performance. Conical burrs, for instance, benefit from gravity, which minimizes heat buildup. In contrast, flat burrs may require more power and generate more heat. The engineering behind burr alignment and shape affects torque requirements and energy efficiency, making careful design crucial for optimal operation.

Motor and Speed Control

The motor drives the burrs, and its performance is crucial. Speed control is essential because higher speeds increase heat, potentially roasting the coffee beans a second time and altering their flavor. A detailed case study describes the specifications needed for motors, such as the use of stepper motors for precise control. Calculations revealed torque requirements of at least 21 N.cm for the X-axis and 177 N.cm for the Y-axis, demonstrating the importance of motor selection and speed management.

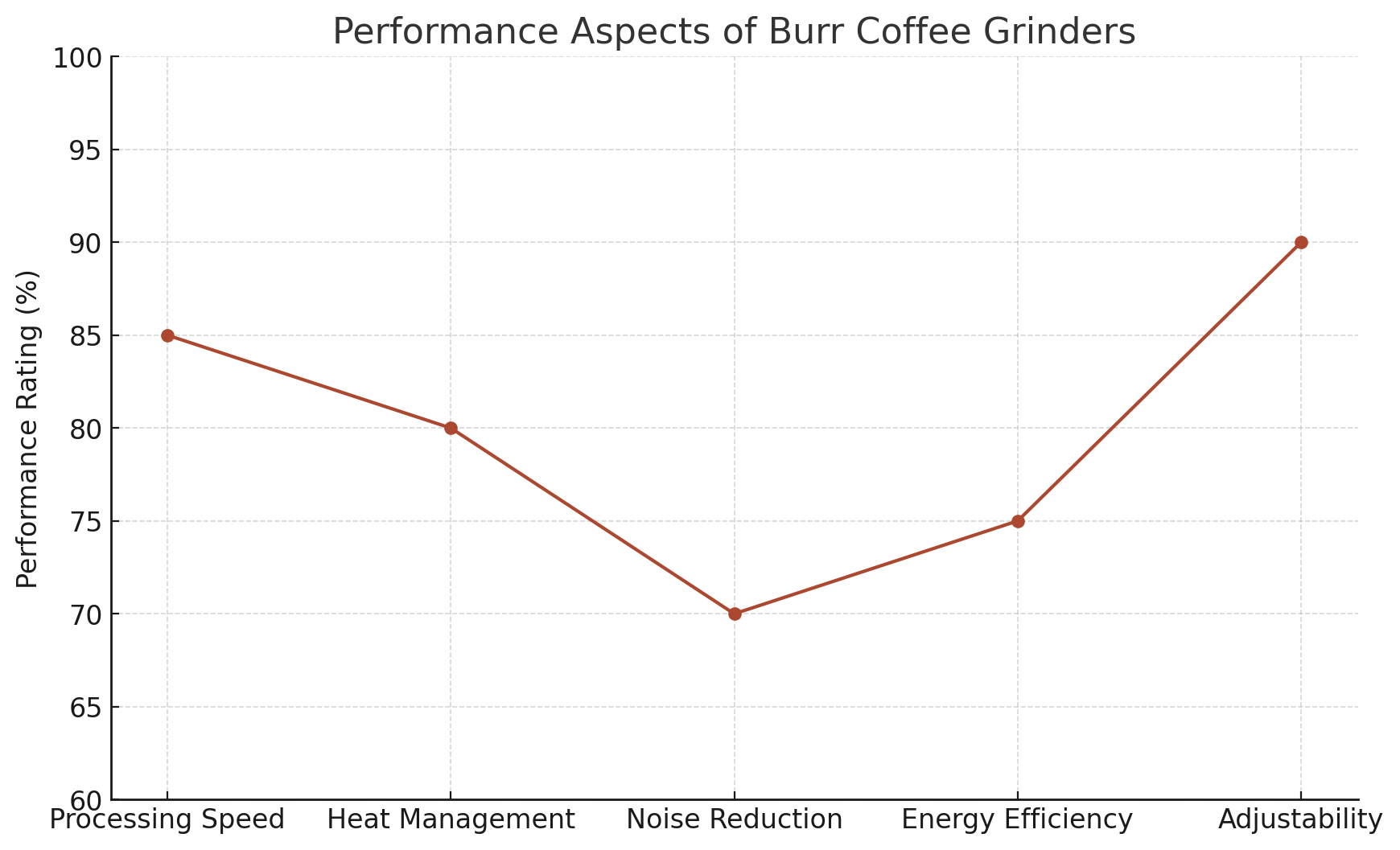

Adjustability

One of the most appealing features of burr grinders is their ability to adjust grind size. This is typically achieved by changing the distance between the burrs, allowing users to customize the grind for different brewing methods. High-end models may offer more precise adjustments, which is critical for brewing techniques like espresso and French press. The case study explains how mechanical components can facilitate these adjustments, adding value for serious coffee enthusiasts.

System Requirements for an Effective Burr Coffee Grinder

Performance Specifications

A burr grinder must deliver consistent grind sizes and operate efficiently to meet industry standards and user expectations. According to stakeholder requirements detailed in the case study, the grinder should be able to process at least 35 grams of coffee in under 30 seconds per cycle. Additionally, the design must adhere to a budget constraint of $500 USD, with a cost-effective approach to components and manufacturing.

Temperature Control

Managing heat during the grinding process is crucial. Excessive heat can lead to secondary roasting, altering the coffee’s flavor profile. The case study highlights the importance of maintaining temperatures below 70°C to prevent this. Factors like friction, burr material, and motor speed influence heat generation. Ceramic burrs are recommended for their lower thermal conductivity compared to metal burrs, which helps in managing heat. Additionally, the use of a cooling system, such as a fan-based mechanism, could be beneficial for large-scale grinders to prevent heat buildup.

Noise and Vibration Considerations

Noise and vibration are common challenges in coffee grinder design. Effective mechanical design can help mitigate these issues. Solutions include using dampening materials and designing the motor housing to minimize vibration transmission. The prototype discussed in the study utilized a frame made from MDF wood, which provided a good balance between cost-effectiveness and stability. This material also helped reduce noise and vibration, but further refinements could enhance performance.

Design and Engineering Considerations

Mechanical Design

The mechanical design of a burr coffee grinder involves several key components, including the grinding mechanism, motor placement, and the structural frame. Stability is essential to ensure that the burrs maintain alignment, as any deflection can impact grind uniformity. The case study includes structural calculations and uses a safety factor of 1.8 to account for simplifications in the torque and deflection models. The design ensures that the platform travels at least 10 cm along the X-axis, providing adequate space for the grinding process.

Mechatronic Integration

A mechatronic approach combines mechanical, electronic, and software systems to create a seamless operation. The burr grinder utilizes stepper motors controlled by an Arduino Mega microcontroller, which allows for precise grinding control. The integration includes limit switches to ensure safety and accurate position sensing. These features emulate industrial applications, with benefits like automatic shutoff and real-time temperature monitoring. This approach demonstrates the potential for using mechatronic systems in high-performance coffee grinders.

Energy Efficiency

Energy efficiency is vital, especially for home and small-scale commercial grinders. The case study outlines a 135 W power supply requirement, optimized with stepper motors that offer high torque at low speeds. By using micro-stepping, the grinder achieves precision without excessive energy use. Additionally, a belt-driven mechanism is employed to reduce energy loss compared to direct drive systems. This energy-saving approach is crucial for sustainable and cost-effective operation.

Prototyping and Testing

Prototype Construction

The initial prototype of the burr coffee grinder was constructed using MDF wood for the frame. MDF was chosen for its affordability and ease of machining, making it an excellent choice for early-stage testing. The frame was laser-cut to ensure precise dimensions and stability during operation. For the grinder housing, lightweight yet durable aluminum was used. This material combination provided a balance between cost and performance, suitable for prototyping and testing.

Integrating both mechanical and electronic components required careful planning. Each system was tested separately to ensure functionality before full assembly. The stepper motors, Arduino Mega microcontroller, and grinding mechanism were connected to form a cohesive system. This meticulous construction process laid the groundwork for effective performance evaluation.

Testing Procedures

The testing phase aimed to evaluate the grinder’s grind size uniformity, motor performance, and temperature management. The prototype was subjected to multiple grinding cycles, with a standard test involving the processing of 35 grams of coffee in 21 to 26 seconds. The results were carefully analyzed, with visual inspections of grind size variations. While the grinder performed well for most brewing methods, the consistency still needed refinement for more demanding applications, such as espresso.

Temperature testing confirmed that the grinder effectively managed heat. The prototype remained below the critical 70°C threshold, indicating that the materials and design effectively mitigated heat transfer. However, the case study suggests that advanced cooling mechanisms could further enhance temperature management, especially for commercial models.

Iteration and Improvement

The initial testing revealed several areas for improvement. The prototype struggled to generate the required torque for consistent grinding, necessitating design modifications. A 1:5 gear reduction system was implemented to increase torque output, and the motor housing was adjusted to reduce friction. These changes improved performance significantly, but further iterations would be necessary to optimize the grinder fully.

Refinements also focused on reducing noise and vibration. By experimenting with different dampening materials and structural reinforcements, the design team aimed to minimize disturbances and improve user experience. These iterative steps underscore the importance of testing and continuous improvement in the development process.

Applications and Use Cases

Home vs. Commercial Burr Grinders

Burr grinders are versatile and cater to various applications, from home use to commercial settings. Home burr grinders emphasize compactness, affordability, and ease of use. They are often constructed with simpler materials, such as plastic housings, and equipped with lower-powered motors. These grinders are suitable for manual brewing methods like pour-over and French press but may lack the precision required for professional-grade espresso.

Commercial burr grinders, on the other hand, are built for heavy-duty performance. They feature robust components, such as stainless steel or cast iron burrs, and powerful motors that can handle large quantities of coffee with high precision. Commercial models often include advanced features like programmable grind settings, integrated temperature monitoring, and automated cleaning. The case study highlights the advantages of stepper motors for precise control, a design that could be scaled up for industrial use.

Special Features for High-End Models

High-end burr grinders come with various features designed to improve usability and performance. These include:

- Precision Grind Adjustment: Some premium models allow for micro-adjustments in grind size, catering to the needs of specialty coffee enthusiasts. The case study emphasizes the importance of fine-tuning and outlines possible mechanisms for achieving this level of precision.

- Temperature Control Systems: Advanced grinders may feature water-cooled or fan-based cooling systems to manage heat. While the prototype did not include these systems, the research suggests their potential for larger-scale applications.

- Noise Reduction Technology: High-end grinders often incorporate materials and design features to minimize noise and vibration. Using MDF wood in the prototype helped with noise reduction, but future iterations could further enhance this aspect.

- Smart Features: Some modern grinders come with smart connectivity, allowing users to control settings via smartphone apps. Although not covered in the case study, this represents an area for future innovation, making coffee grinding more user-friendly and customizable.

Conclusions

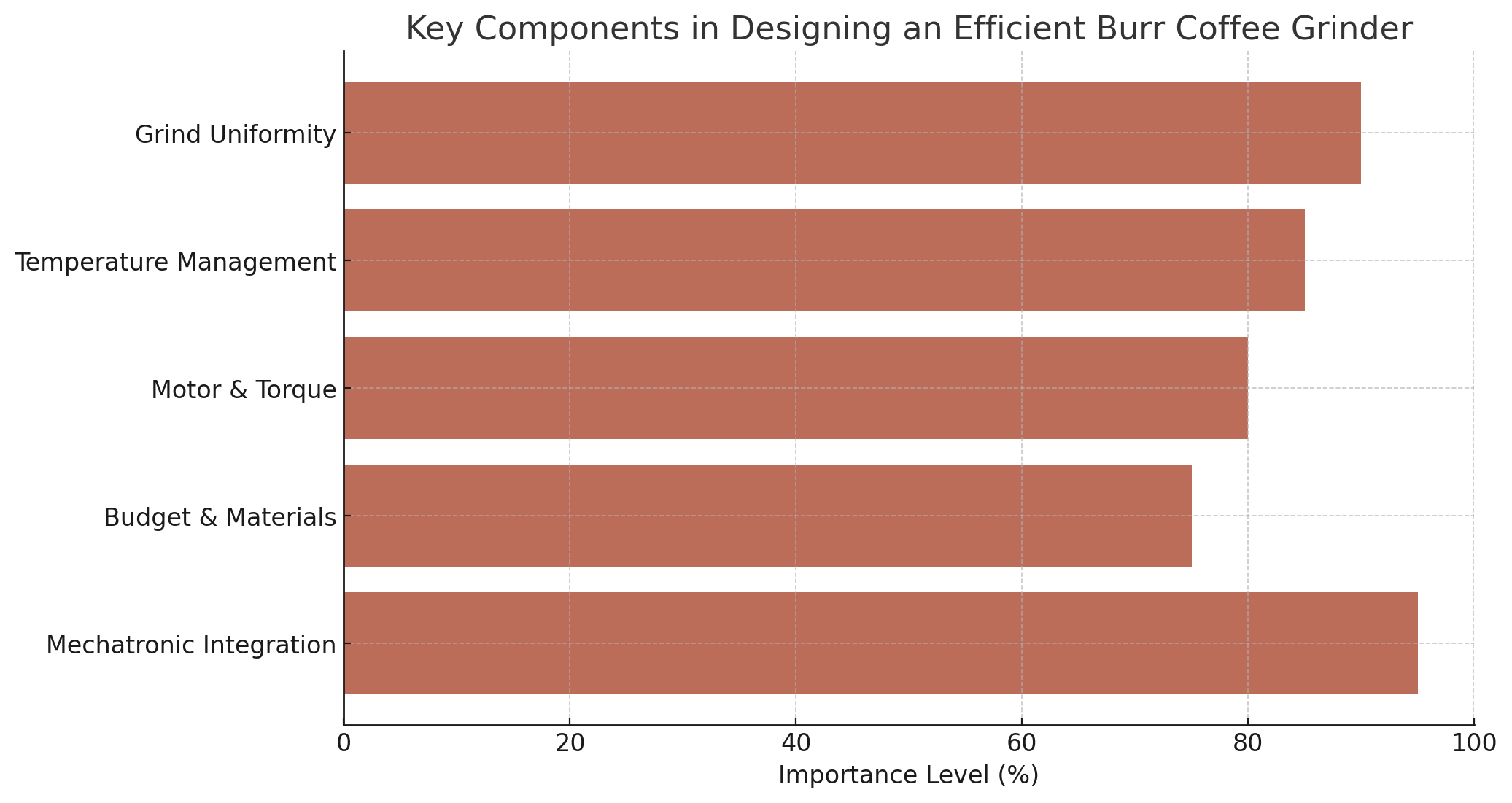

Designing an efficient burr coffee grinder requires addressing various engineering challenges while balancing performance, cost, and energy efficiency. By adopting a mechatronic approach, engineers can integrate mechanical, electronic, and software systems to create a high-performance grinder that meets the needs of both home users and commercial operations.

Summary of Key Findings

- Grind Uniformity: Burr grinders, especially conical burr models, deliver superior grind uniformity compared to blade grinders. The study demonstrated that even with budget constraints, the prototype could achieve adequate uniformity for standard brewing methods. However, for specialty applications like espresso, further refinements are needed.

- Temperature Management: Managing heat generation is critical to preserving coffee flavors. The prototype effectively kept temperatures below the 70°C threshold, thanks to the use of ceramic burrs and efficient motor speed control. Future versions could explore more advanced cooling mechanisms to enhance performance for larger grinders.

- Motor and Torque Requirements: The case study underscored the importance of motor specifications. Initial torque calculations highlighted the need for a powerful motor and gear system to achieve consistent grinding. Implementing a 1:5 gear reduction significantly improved torque output, demonstrating the effectiveness of design adjustments.

- Budget and Material Constraints: Working within a $500 USD budget presented challenges in material and component selection. Despite these limitations, the prototype successfully showcased that cost-effective solutions could still deliver quality grinding performance. Using higher-end materials could further elevate the grinder’s capabilities in future designs.

- Mechatronic Integration: Integrating mechanical and electronic systems provided precise control and automation. The use of an Arduino Mega microcontroller facilitated features like speed control and automatic shutoff, paving the way for further advancements in smart grinding technology.

The development of a burr coffee grinder exemplifies the complexity of combining multiple engineering disciplines. By refining each component and continuously iterating on the design, it is possible to create a product that meets the high standards of coffee enthusiasts while remaining efficient and cost-effective.