Industrial Wood Chip Burner System

- Provide a renewable and potentially cost-effective way to generate heat for the drum dryer

- Allow for real-time monitoring of wood chip moisture content within the drum

- Utilize waste materials from forestry or sawmills, minimizing waste

What is the industrial wood chip burner system ?

The industrial wood chip burner system is a type of biomass heating system that uses wood chips as fuel to generate heat for industrial applications. These systems are designed to be highly efficient and are capable of handling various fuel qualities, including waste or recycled wood chips. They are typically fully automated, meaning they can automatically ignite, feed fuel to the fire, and switch off as needed.

- Sustainable Heat Generation and Cost Savings: The Wood Chip Burner System prioritizes a renewable and potentially cost-effective approach to heat generation. It utilizes wood chips or sawdust as fuel, a readily available resource that can be more eco-friendly and potentially cheaper compared to traditional fossil fuels. This shift towards renewable fuel contributes to a smaller environmental footprint and potentially reduces operational costs.

- Real-Time Monitoring and Optimized Drying: The system goes beyond sustainable heating by incorporating real-time monitoring of wood chip moisture content within the drum. This crucial data, captured by integrated humidity sensors, empowers operators to precisely adjust the burner temperature based on the specific needs of the drying material. This level of control over the drying process can optimize drying efficiency and ensure consistent results in the final product.

Technical Specifications

Product's functions

- The combustion burner supplies hot air into the drum dryer to evaporate water in the drying materials (wood chips, sawdust).

- The industrial burner‘s humidity sensors help the operator easily recognize the input material’s current humidity in the drying drum, thereby, it is easy to decide whether to increase or decrease the burner temperature accordingly.

Product's specifications

| BURNER SYSTEM SPECIFICATIONS | |

| Heat capacity | 6000 ÷ 10.000 kW |

| Burner type | Fluid bed grate |

| Combustion material | Wood chips, dimensions 30×30 mm, thickness 5 – 10 mm |

| Moisture of combustion material | < 40% |

| Burner control | Automatically control and via PLC screen |

| Control and display functions | – Control fan speed according to drying temperature – Adjusting the combustion material supplied to the combustion chamber – Periodic slag collection – Adjusting the valve to take fresh air into the dryer – Automatically release smoke when detecting problems in the drying system |

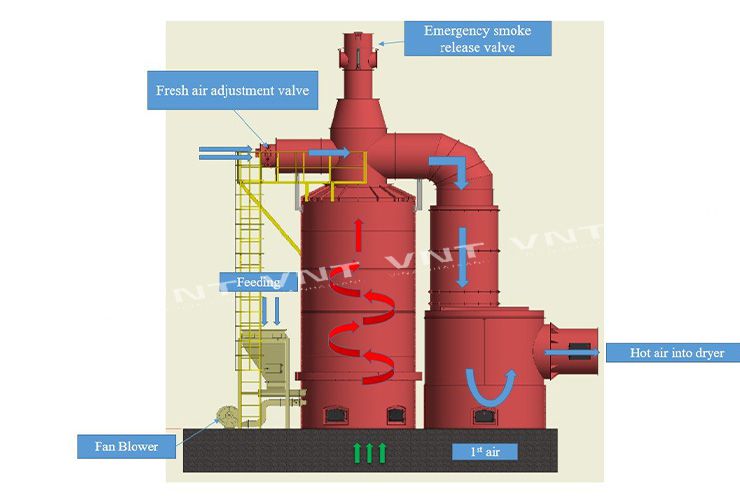

Product's principle of operation

- In the combustion burner, combustion material is fed into the combustion chamber through a screw conveyor, and based on the fan blower, the material will be evenly spread on the surface of the fluidized bed.

- The blower below the fluidized bed adjusts the airflow to create stable combustion in the combustion chamber.

- Blower level 2, providing oxygen to burn the remaining ashes.

- The hot air from the combustion chamber will be mixed with the fresh outdoor air, providing enough heat for the dryer capacity.

- During the drying process, when detecting the problem, the exhaust valve will automatically open to release the smoke outside.

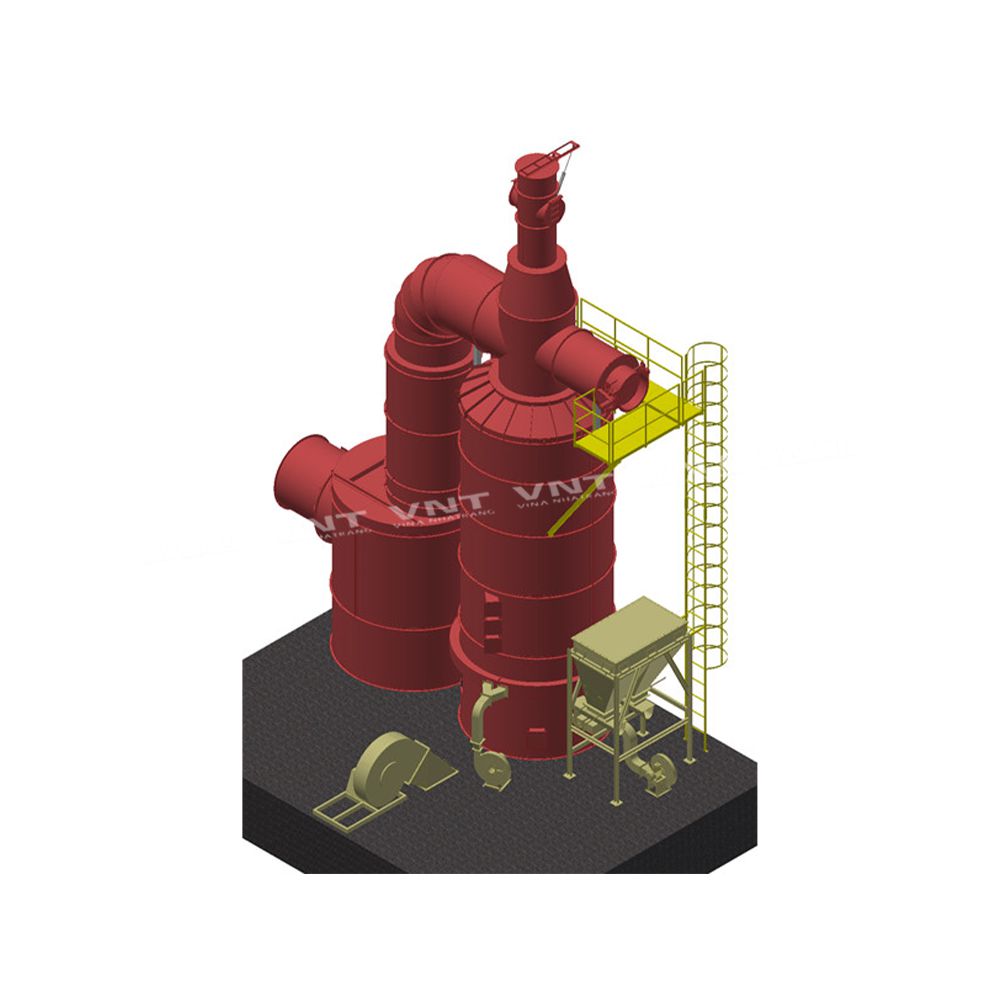

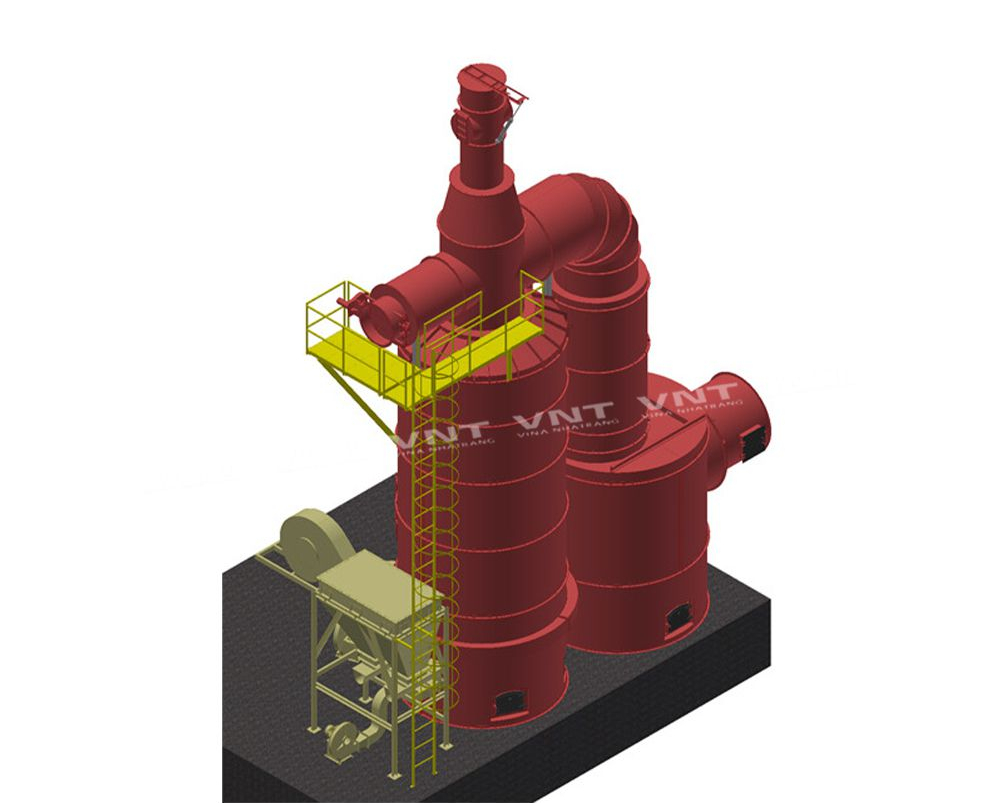

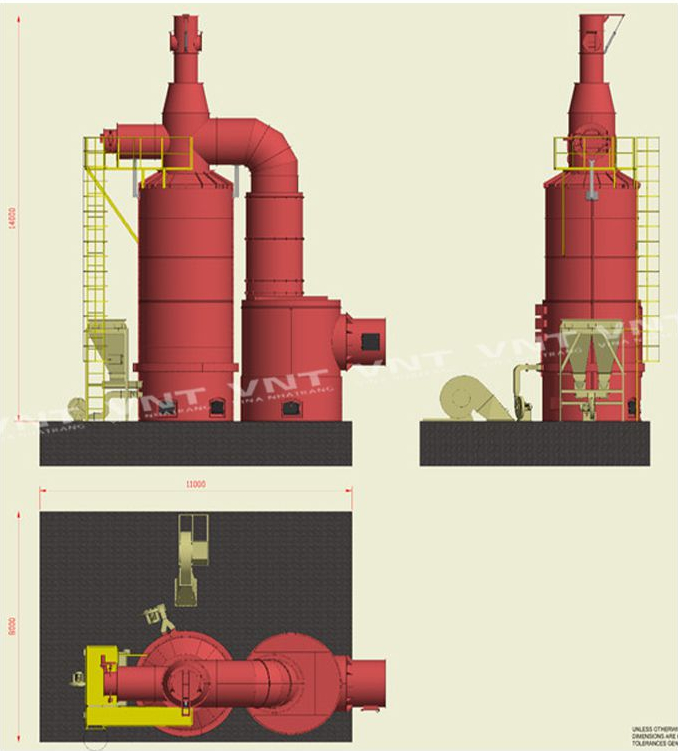

Product's pictures of burner

Product's advantages

- Automatic temperature control

- Reducing drying time

- Modern technology

- High durability

- Easy to operate

- Electricity saving

- Improve processing efficiency for the whole system

- Minimize labor workforce in the processing line

Frequently Asked Questions

I want to know how to visit VNT's sample system?

Vina Nha Trang has more than 30 years of experience in manufacturing equipment and systems for processing agricultural products such as coffee, pepper, and cocoa … in Vietnam and over the world. Depending on your requirement for machine capacity and the factory’s location, we will give the most helpful advice as well as arrange a suitable place for you to visit. Please contact our hotline at (+84) 966 757 757 to get more information.

I want to know about VNT warranty policy?

The Vina Nha Trang provides free warranty service within 12 months from the Delivery Date for mechanical parts.

I want to know how to contact to VNT?

Please contact our hotline at (+84) 966 757 757 for support. In addition, you can leave a message in the “CONTACT FOR QUOTATION” section below, we will get back to you within 24 hours.