WOOD CHIPS DRYING SYSTEM

- Excels at drying wood chips and sawdust, removing excess moisture that hinders the creation of high-quality fuel pellets.

- Can adapts to various production volumes, allowing producers to optimize their drying process for efficiency.

What is the wood chips drying system ?

The VNT's Wood Chip Dryer or Wood Chip Drying System plays a critical role in ensuring the quality of wood pellets, a renewable fuel source. Within the wood pellet production process, proper drying of wood chips is essential.

- Precise Moisture Control for Optimal Pellets: The Wood Chip Drying System is designed to meticulously control and guarantee that the final moisture content of wood chips or sawdust falls below 12%. This precise drying ensures high-quality wood chips that are perfectly suited for the pelletizing machine. This translates directly to the production of high-quality wood pellets, a reliable and efficient fuel source.

Technical Specifications

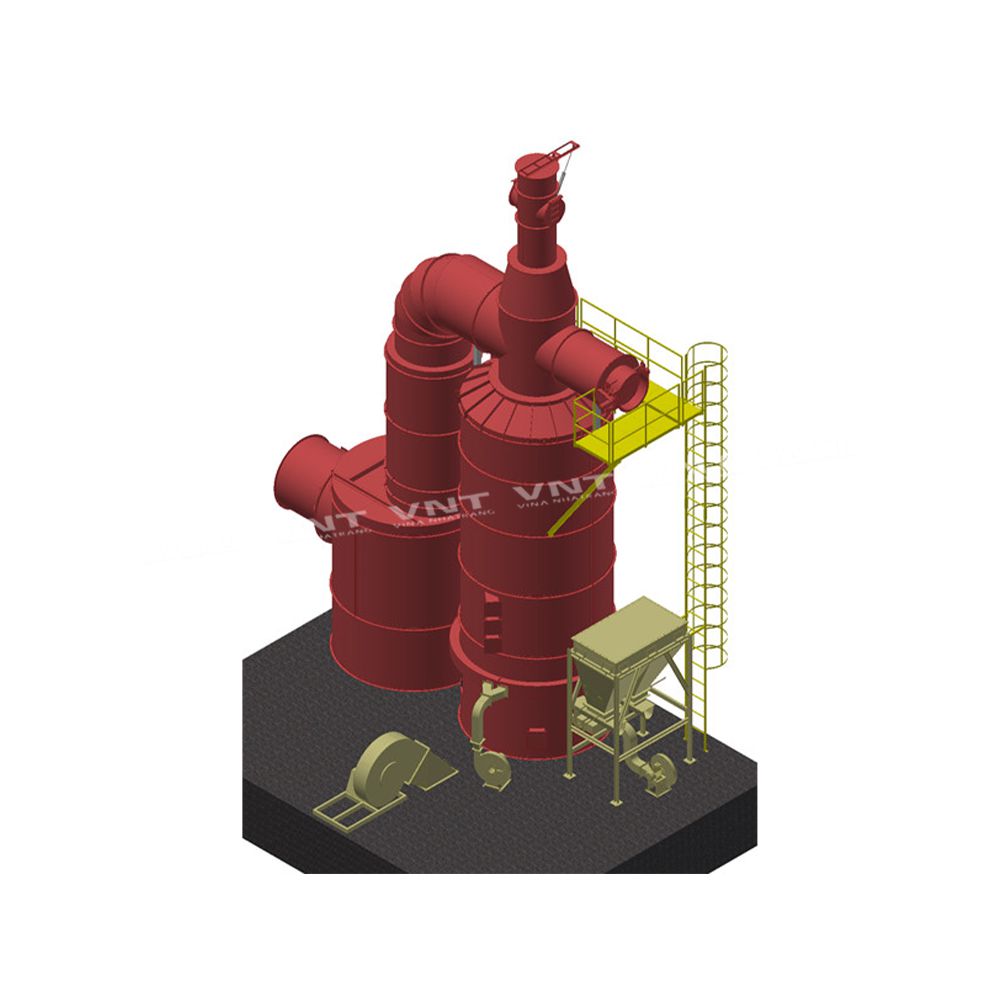

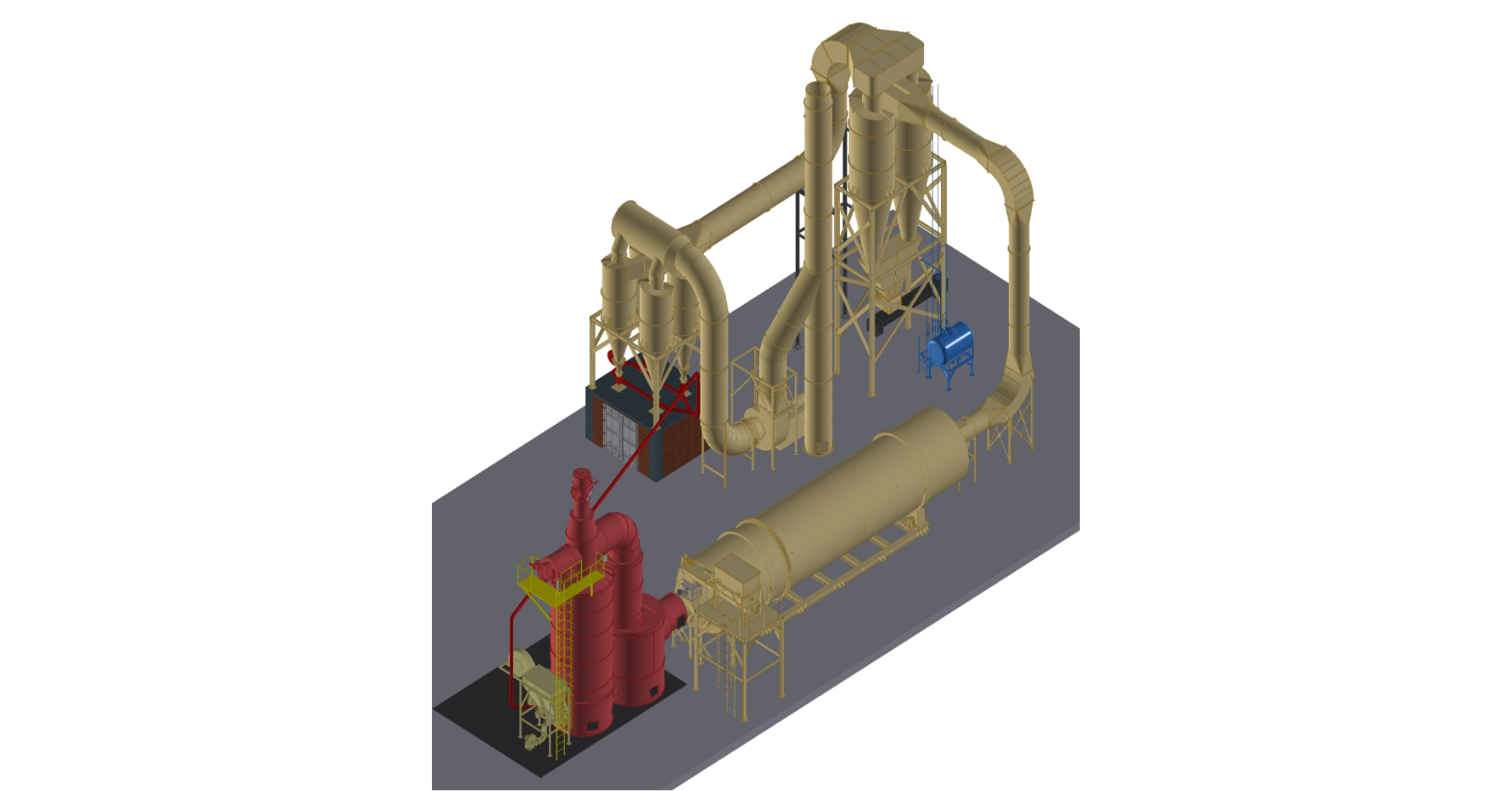

Product's overall diagram

Product's functions

- Wood chips drying system is used to evaporate water and dry fiber-type wood chips/sawdust for the needs of processing wood pellets in fuel technology

- The drum dryers for wood chips are designed on single and multi-pass technology according to customer requirement

Product's specifications

| Model | Input Moisture (MC%) | Output Moisture (MC%) | Water Evaporation (Kg/H) | Ouput Capacity (Kg/H) |

| MSG – 6T | 45 ÷ 50 | 12 ± 2% | 4,800 | 6,000 ÷ 8,000 |

| MSG – 8T | 45 ÷ 50 | 12 ± 2% | 6,000 | 8,000 ÷ 10,000 |

| MSG – 10T | 45 ÷ 50 | 12 ± 2% | 7,600 | 10,000 ÷ 12,000 |

| MSG – 12T | 45 ÷ 50 | 12 ± 2% | 9,120 | 12,000 ÷ 14,000 |

- Drum length: 15 – 18 meters

- Drum diameter: 3.2 – 4 meters

Product's principles of operation

- The wood chip drying systems feature single and multi-pass technology that moves material (wood chips/sawdust) through the drum in an air stream created by the dryer-induced-draft fan. Multiple passes are mechanically interlocked to rotate at the same speed. As the drum rotates, the product is repeatedly showered into the rotary wood chip dryer’s hot air.

- Depending on customers’ requirements, the wood chips drying system manufactured by Vina Nha Trang can evaporate water up to 9000 kg/hour.

Product's automatic operation

- Furnace burner and drum dryer are automatically controlled via the PLC screen.

- The wood chips dryer machine’s humidity sensor system adjusts the drying temperature continuously to help the output material (wood chips/sawdust) always meet the standard moisture.

Product's safety fire control

- Temperature and spark sensors are installed on the whole drying wood chips system.

- The system will automatically stop running and activate the water spray when the sensor detects fire signs.

- Safe control mode reduces the risk of fire and explosions caused by human mistakes.

Product's safe environment

- The wood chips/sawdust dryer with a 2-level cyclone filter system helps to minimize the amount of dust released into the environment.

Product's pictures of system

Product's advantages

- The dust filter system through 2 levels of the cyclone will increase the efficiency of the wood shavings dryer machine.

- Minimize the dust released into the environment

- Gear-driven rotary drum drying system should operate stably, and be easy to maintain.

- Ensure the required quality of wood chips/sawdust to make wood pellets

- Modern technology

- High durability

- Easy to operate

- Electricity saving

- Improve processing efficiency for the whole system

- Minimize labor workforce in the processing line

Frequently Asked Questions

What is the maximum capacity of the actual wood chips drying system installed by VNT?

Vina Nha Trang Company is proud to be the top commercial wood chip dryer manufacturer in Vietnam to produce the largest capacity, applied to modern standards and technology from Europe, with a capacity of 15 tons/hour and an output humidity below 12%. If you need to design wood drying equipment with a higher capacity, please contact VNT for more details.

What is the design of drum dryer?

The VNT drum dryer for wood chips is designed with 3-pass technology to increase the distance of wood chips in the drum. It will increase drying efficiency and quality, and ensure the output moisture is below 12%. If you want to design a 1-pass or multi-pass drum dryer, please contact VNT for more details.

How long does it take to manufacture and install a wood chips drying system?

Depending on the wood chips/sawdust drying equipment’s capacity and the location of the customer’s factory, VNT can determine the most appropriate time for manufacturing and installation. Basically, the manufacturing time for a wood chips dryer system takes about 2 months, and an additional 1 month to transport and install at the customer’s factory.

I want to know how to visit VNT's sample system?

Vina Nha Trang has more than 30 years of experience in manufacturing equipment and systems for processing agricultural products such as coffee, pepper, wood chips, and cocoa … in Vietnam and over the world. Depending on your requirement for machine capacity and the factory’s location, we will give the most helpful advice as well as arrange a suitable place for you to visit. Please contact our hotline at (+84) 966 757 757 to get more information.

I want to know about VNT warranty policy?

Vina Nha Trang provides free warranty service within 12 months from the Delivery Date for mechanical parts.

I want to know how to contact to VNT?

Please contact our hotline at (+84) 966 757 757 for support. In addition, you can leave a message in the “CONTACT FOR QUOTATION” section below, we will get back to you within 24 hours.