In recent years, the instant coffee market has undergone a remarkable transformation. No longer relegated to the realm of convenience at the expense of quality, specialty instant coffee has emerged as a legitimate option for discerning coffee enthusiasts. Behind this evolution lies two distinct production methods: spray-drying and freeze-drying. Understanding the differences between these processes provides valuable insight into why some instant coffees preserve more of the complexity and character of freshly brewed coffee than others.

For today’s consumer, knowledge of production methods translates directly into more informed purchasing decisions. Whether you’re seeking convenience for travel, camping, or simply a quick morning cup, the method used to transform liquid coffee into soluble granules significantly impacts what ends up in your cup. Let’s explore the science, history, and sensory differences between spray-dried and freeze-dried instant coffee to help you navigate this expanding market with confidence.

How is Spray-Dried Instant Coffee Made?

Spray-drying represents the original and still most common method for producing instant coffee worldwide. This efficient, cost-effective process transforms brewed coffee into the familiar powder many associate with traditional instant coffee.

The Spray-Drying Production Process Explained

- Coffee Extraction: The process begins with brewing ground coffee beans in water under high pressure and temperature to create a concentrated coffee extract.

- Concentration: This extract is further concentrated by removing a portion of the water, typically through evaporation under vacuum conditions.

- Atomization: The concentrated coffee liquid is then pumped to the top of a tall drying tower and forced through small nozzles, creating a fine mist of tiny droplets.

- Hot Air Contact: As these droplets fall through the tower, they encounter a blast of hot air (typically 250°C/482°F or higher) moving in either the same direction (co-current) or the opposite direction (counter-current).

- Instantaneous Drying: The extreme heat causes the water in each droplet to evaporate almost immediately, leaving behind dried coffee solids.

- Collection: The resulting powder collects at the bottom of the tower and is then processed for packaging.

The Science Behind Atomization and Hot Air Drying

Spray-drying relies on the principle of maximizing surface area to accelerate evaporation. By converting the coffee concentrate into microscopic droplets, the process creates an enormous surface area relative to volume. This allows for rapid moisture removal—often in just 5-30 seconds—as the droplets fall through the heated chamber.

The speed of this process is critical; while the air temperature is extremely high, the actual temperature experienced by the coffee particles (known as the “wet bulb temperature”) remains much lower due to evaporative cooling, typically around 85-90°C (185-194°F).

Equipment and Technology Requirements

A commercial spray-drying operation requires:

- Brewing equipment for initial extraction

- Evaporation systems for concentration

- High-pressure pumps for atomization

- Specialized atomizing nozzles or spinning discs

- A tall drying chamber (often 15-30 meters/50-100 feet high)

- Hot air generation and circulation systems

- Collection systems for the dried product

- Sophisticated control systems to manage temperature and airflow

Temperature Impact on Flavor

The high temperatures involved in spray-drying present a significant challenge for flavor preservation. Coffee contains hundreds of volatile aromatic compounds that contribute to its complex flavor profile. Many of these compounds are heat-sensitive and evaporate or break down during the intense heating process.

This thermal degradation explains why many spray-dried coffees exhibit noticeably different flavor profiles compared to their freshly brewed counterparts, often with:

- Reduced aromatic complexity

- More pronounced bitter notes

- Less distinct origin characteristics

- A more generic “coffee” flavor

Historical Development of Spray-Drying

Spray-drying technology for coffee emerged in the 1950s as an improvement over earlier drum-drying methods. Companies like Nestlé and General Foods (now part of Kraft Heinz) pioneered the commercial application of this technology, which allowed for much larger-scale production than previous methods.

The post-World War II economic boom created increased demand for convenient food products, and spray-dried instant coffee became a household staple during this period. Continuous improvements in atomization technology and temperature control have gradually improved quality, though the fundamental process remains similar.

Production Scale and Cost Efficiency

Spray-drying excels in terms of production efficiency:

- High throughput capacity (can process thousands of pounds per hour)

- Lower equipment investment compared to freeze-drying

- Lower energy consumption per pound of finished product

- Continuous rather than batch processing capabilities

- Relatively simple operation and maintenance

These efficiency advantages translate into significantly lower production costs, which explains why spray-dried coffee dominates the lower and mid-range instant coffee market segments.

Characteristics of Spray-Dried Instant Coffee

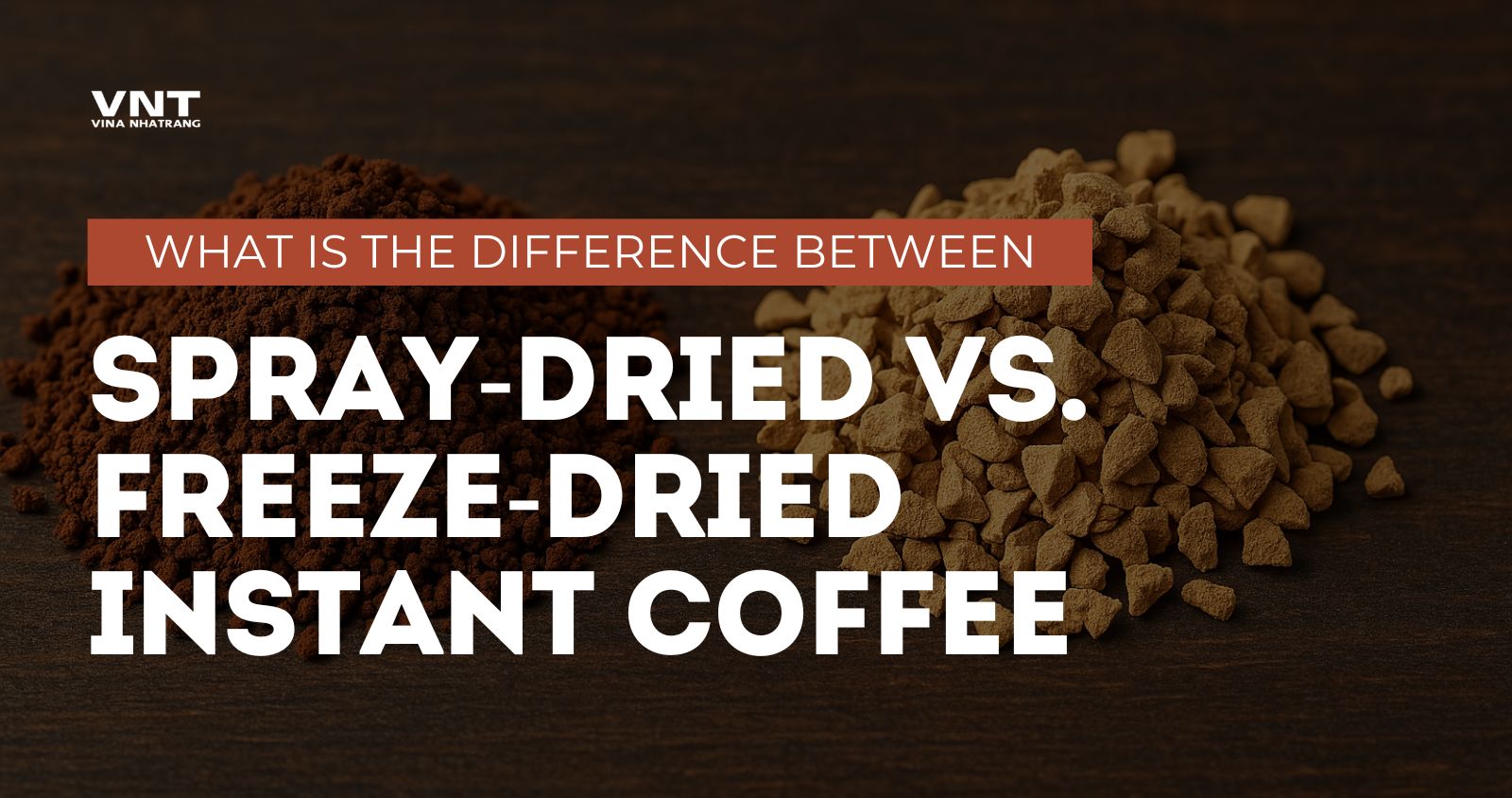

Appearance: Spray-dried instant coffee typically consists of fine, light brown powder or small, irregular granules with a relatively uniform color. The particles are often porous but may appear somewhat dense.

Solubility: Dissolves quickly in water, often in seconds, due to the porous nature and small particle size.

Flavor Profile: Generally characterized by stronger, sometimes sharper flavor notes with less complexity than the original brewed coffee. Often exhibits more pronounced bitter and burnt notes due to the high-temperature processing.

How is Freeze-Dried Instant Coffee Made?

Freeze-drying represents a more sophisticated and gentle approach to creating instant coffee, preserving more of the original coffee’s sensory qualities through a complex, multi-stage process.

The Freeze-Drying Process Explained

- Coffee Extraction: Similar to spray-drying, the process begins with brewing coffee beans to create a concentrated extract.

- Initial Freezing: The coffee extract is rapidly frozen to approximately -40°C (-40°F) or lower, typically on stainless steel belts or trays.

- Granulation: The frozen coffee is broken into particles of the desired size, often through a process called “grinding” (despite taking place while frozen).

- Primary Drying (Sublimation): The frozen particles are placed in vacuum chambers where, under precise low-pressure conditions, the ice directly transforms from solid to vapor without passing through a liquid state.

- Secondary Drying (Desorption): An additional drying phase removes residual moisture that remains bound to the coffee solids.

- Final Processing: The dried particles may undergo additional processing such as screening for size uniformity before packaging.

The Science of Sublimation in Coffee Preservation

Freeze-drying leverages the physical phenomenon of sublimation—the direct transition of a substance from solid to gas phase without passing through the liquid state. This occurs when a frozen substance is placed in a vacuum below the triple point of water (the temperature and pressure at which solid, liquid, and gas phases can coexist).

For coffee, this gentle process preserves many volatile compounds that would otherwise be lost during conventional heating. The ice crystals sublimate and leave behind a porous structure that closely resembles the original frozen material, creating a “structural memory” that helps retain aromatic compounds.

Equipment and Technology Requirements

Freeze-drying requires sophisticated equipment:

- Initial coffee brewing and concentration systems

- Specialized freezing equipment capable of rapid, uniform freezing

- Large vacuum chambers with precise pressure control

- Powerful vacuum pumps and condenser systems

- Heating elements for controlled energy input during sublimation

- Sensors and control systems for monitoring the process

- Secondary drying capabilities

- Size classification and packaging systems

Temperature Management During Freeze-Drying

Temperature control during freeze-drying is critical but fundamentally different from spray-drying:

- Initial freezing must be rapid to create small ice crystals

- Product temperature during primary drying typically ranges from -20°C to -40°C (-4°F to -40°F)

- As drying progresses, controlled heat is applied to provide energy for sublimation without allowing the product to thaw

- Final temperatures during secondary drying may reach 25-35°C (77-95°F), still far lower than spray-drying

This low-temperature processing is key to preserving heat-sensitive flavor compounds.

Historical Development and Market Positioning

Freeze-drying technology was initially developed for medical applications in the 1940s but was adapted for food preservation in the 1950s. The first commercial freeze-dried coffee appeared in the 1960s, with brands like Maxim (General Foods) pioneering the market.

From the beginning, freeze-dried coffee positioned itself as a premium alternative to spray-dried options, emphasizing superior flavor preservation. This quality differentiation continues today, with freeze-dried products generally occupying higher price points in the instant coffee market.

Production Costs and Scaling Considerations

Freeze-drying’s superior quality comes with significant production challenges:

- Higher equipment capital costs (often 4-5 times that of spray-drying)

- Greater energy consumption per pound of finished product

- Longer processing times (typically 16-20 hours vs. seconds for spray-drying)

- Batch processing rather than continuous operation

- More complex operation and maintenance requirements

These factors contribute to production costs that may be 2-3 times higher than spray-drying, explaining the price premium typically associated with freeze-dried instant coffee.

Characteristics of Freeze-Dried Instant Coffee

Appearance: Freeze-dried coffee consists of larger, more irregular granules with a porous, almost sponge-like structure. The color tends to be less uniform, often showing variations that reflect the original brewed coffee.

Solubility: Dissolves relatively quickly, though sometimes slightly slower than spray-dried varieties due to larger particle size. The porous structure allows water to penetrate efficiently.

Flavor Profile: Generally preserves more of the original coffee’s aromatic compounds, resulting in greater complexity and distinction between different coffee origins. Typically exhibits fewer bitter or burnt notes compared to spray-dried alternatives.

What Are the Key Differences Between Spray-Dried and Freeze-Dried Instant Coffee?

Flavor Retention Comparison

The most significant difference between these methods lies in their ability to preserve the original coffee’s flavor compounds:

Spray-Dried Coffee:

- Loses a substantial portion of volatile aromatics during high-temperature processing

- Tends to develop additional “cooked” or “thermal” notes

- Often results in a flatter, more one-dimensional flavor profile

- May preserve stronger base notes but loses nuance

Freeze-Dried Coffee:

- Retains approximately 80-90% of volatile aromatics (compared to 15-20% for spray-drying)

- Preserves more distinct origin characteristics

- Maintains better acid-sweet balance

- Exhibits greater flavor complexity and clarity

Aroma Preservation Differences

Coffee aroma, comprising hundreds of volatile compounds, shows marked differences between the two methods:

Spray-Dried Coffee:

- Often exhibits a distinctly “instant coffee” aroma

- Frequently displays stronger roasty, sometimes burnt aromatic notes

- Shows reduced floral, fruit, and specialty coffee characteristics

- May develop processing-related aromas not present in the original brew

Freeze-Dried Coffee:

- Presents a more authentic “fresh coffee” aromatic profile

- Better preserves delicate high notes (floral, fruity, acidic)

- Retains more distinctive origin-specific aromatics

- Shows less influence from the production process itself

Appearance and Texture Comparison

Visual and tactile differences make it relatively easy to distinguish between these products:

Spray-Dried Coffee:

- Fine powder to small, regular granules

- Relatively uniform color and texture

- Lighter, more airy consistency

- Smoother surface appearance

Freeze-Dried Coffee:

- Larger, more irregular chunks

- Variable internal structure visible in larger pieces

- More variations in color tone

- Clearly visible porous, almost sponge-like texture

- Harder, more brittle feel when compressed

Dissolution Characteristics

How the coffee dissolves affects both convenience and the drinking experience:

Spray-Dried Coffee:

- Typically dissolves almost instantly

- May form more foam on the surface

- Sometimes leaves fine particles suspended in the liquid

- Generally requires minimal stirring

Freeze-Dried Coffee:

- Dissolves quickly but may take slightly longer than spray-dried

- Often shows a more cascading dissolution pattern as water penetrates the porous structure

- Generally creates less surface foam

- May release aromatic compounds more gradually during dissolution

Shelf Stability and Packaging

Both methods create products with excellent shelf stability, but subtle differences exist:

Spray-Dried Coffee:

- Typically has slightly lower residual moisture (2-3%)

- More compact powder is less susceptible to physical damage

- Less internal surface area means slightly better resistance to oxidation

- Often packaged in simpler packaging due to lower cost positioning

Freeze-Dried Coffee:

- Slightly higher residual moisture (typically 2-4%)

- More fragile physical structure requires more protective packaging

- Greater internal surface area can make it marginally more susceptible to oxidation

- Often features more sophisticated packaging with better oxygen barriers to protect the preserved flavors

Production Costs and Price Implications

The economic differences significantly impact market positioning:

Spray-Dried Coffee:

- Lower production costs ($2-4 per pound of finished product)

- Higher production efficiency and throughput

- Lower energy consumption per unit

- Dominates the mass market and lower-price segments

Freeze-Dried Coffee:

- Higher production costs ($6-12 per pound of finished product)

- Lower production efficiency and throughput

- Higher energy consumption per unit

- Positioned primarily in premium market segments

Environmental Impact Considerations

The environmental footprint differs between the methods:

Spray-Drying:

- Higher carbon footprint from intense heat generation

- Lower water usage during production

- More energy-efficient packaging due to higher density

- Lower transportation emissions per serving due to compact form

Freeze-Drying:

- Lower direct heat emissions but higher electricity usage for refrigeration and vacuum systems

- Higher overall energy consumption per pound produced

- Greater packaging requirements due to product fragility

- Higher transportation emissions per serving due to lower density

Market Positioning and Consumer Perception

How each product is perceived in the marketplace:

Spray-Dried Coffee:

- Generally perceived as “conventional” instant coffee

- Associated with convenience over quality

- Dominant in food service, institutional, and mass-market retail channels

- Often the default choice for cost-conscious consumers

Freeze-Dried Coffee:

- Positioned as premium instant coffee

- Marketed based on quality and flavor preservation

- Growing presence in specialty coffee channels

- Preferred by consumers willing to pay more for better flavor

Side-by-Side Comparison: Spray-Dried vs. Freeze-Dried Instant Coffee

| Feature | Spray-Dried Instant Coffee | Freeze-Dried Instant Coffee |

|---|---|---|

| Production Method | High-temperature atomization | Low-temperature sublimation |

| Production Time | Seconds | 16-20 hours |

| Temperature Range | 150-300°C (302-572°F) | -40 to 35°C (-40 to 95°F) |

| Flavor Retention | 15-20% of volatile compounds | 80-90% of volatile compounds |

| Appearance | Fine powder or small granules | Larger, porous chunks |

| Color | Uniform light to medium brown | Variable with visible variations |

| Texture | Smooth, fine particles | Porous, sponge-like structure |

| Dissolution Speed | Very rapid (2-3 seconds) | Quick (3-5 seconds) |

| Aroma | Less pronounced, more “cooked” | More vibrant, closer to fresh brew |

| Relative Cost | $ | $$$ |

| Energy Usage | Moderate | High |

| Shelf Life | 1-2 years | 1-2 years |

| Best For | Cost-efficiency, large scale production | Premium products, flavor preservation |

How Do Blind Taste Tests Compare These Products?

Research and industry blind tastings consistently show significant preferences for freeze-dried products when participants are unaware of the production method. Key findings from aggregated studies include:

- 70-80% of participants typically prefer freeze-dried over spray-dried in direct comparisons

- The preference gap widens among specialty coffee consumers and narrows among traditional instant coffee users

- When prepared with milk and sugar, the difference becomes less pronounced

- In black coffee evaluations, freeze-dried products score approximately 15-25% higher on flavor complexity ratings

- Spray-dried products are often described as having more intense but less complex flavor

- Freeze-dried coffees are more frequently described using specialty coffee terminology (fruity, floral, chocolatey) rather than generic coffee descriptors (strong, bitter, roasty)

Professional coffee tasters (Q-graders) typically score freeze-dried coffees 8-12 points higher on the standard 100-point cupping scale compared to spray-dried equivalents made from the same coffee.

How Can You Identify Which Method Was Used?

When purchasing instant coffee, several indicators can help you determine whether it’s spray-dried or freeze-dried:

Visual Inspection

- Spray-dried coffee appears as a fine powder or small, uniform granules

- Freeze-dried coffee consists of larger, irregularly shaped pieces with visible internal structure

Packaging Claims

- Premium products often explicitly state “freeze-dried” on packaging

- Terms like “crystal” or “crystallized” typically indicate freeze-drying

- Budget-oriented products rarely specify the method (usually spray-dried)

Price Point

- Significantly higher-priced products are more likely to be freeze-dried

- Entry-level or store brand options are almost always spray-dried

Marketing Language

- Emphasis on “flavor preservation” or “aroma lock” suggests freeze-drying

- Focus on “quick dissolution” or “convenience” without quality claims often indicates spray-drying

Which Type of Instant Coffee Is Best for Different Uses?

For Travel and Outdoor Activities

- Spray-dried offers advantages for backpacking due to lighter weight and more compact size

- Freeze-dried is preferable for situations where quality matters more than saving space

For Home and Office Use

- Freeze-dried provides a significantly better coffee experience for daily consumption

- Spray-dried may be sufficient when used primarily with milk, sugar, or flavorings

For Cooking and Baking

- Spray-dried is often more economical and sufficient for most recipes

- Freeze-dried offers superior results in applications where coffee is a central flavor (mousses, ice creams, etc.)

For Coffee Enthusiasts

- Freeze-dried specialty offerings can provide a surprisingly authentic specialty coffee experience

- Spray-dried products, even premium ones, typically fall short for discerning palates

The Future of Instant Coffee Production

The instant coffee market continues to evolve, with notable trends including:

- Hybrid Processing Methods: Some manufacturers are developing combined techniques that incorporate elements of both spray and freeze-drying to optimize quality and cost.

- Cold Brew Instant Coffee: Specialized freeze-drying of cold brew concentrates represents a growing premium segment.

- Single-Origin Freeze-Dried Offerings: Specialty coffee companies increasingly offer freeze-dried versions of their premium single-origin coffees.

- Improved Spray-Drying Technology: Advancements in lower-temperature spray-drying aim to close the quality gap while maintaining cost advantages.

- Sustainable Processing Focus: Both methods are being refined to reduce energy consumption and environmental impact.

Understanding the fundamental differences between spray-dried and freeze-dried instant coffee allows consumers to make informed choices based on their priorities—whether seeking the most authentic coffee experience or balancing quality with cost considerations. As production technology continues to advance, the gap between instant and freshly brewed coffee continues to narrow, particularly in the premium freeze-dried segment.