Spray Drying Technology

Achieving the perfect balance between product quality, efficiency, and profitability is a constant pursuit, especially for coffee business owners. In the ever-evolving world of food processing, spray drying technology has emerged as a game-changer, offering a solution that can elevate your instant coffee offerings to new heights. This innovative technique has revolutionized the way we preserve and package the beloved morning brew, ensuring that the rich aroma and flavor of freshly brewed coffee can be enjoyed at any time, anywhere.

In this comprehensive guide, we’ll explore the intricacies of spray drying technology, its advantages, challenges, and applications beyond the realm of instant coffee. Whether you’re a seasoned coffee entrepreneur or a newcomer to the industry, understanding the power of this innovative process is essential to staying ahead of the curve and meeting the ever-evolving demands of the modern consumer.

History of Spray Drying Technology

The origins of spray drying technology can be traced back to the pioneering work of French scientist Alexis Millardet in the 19th century. His groundbreaking experiments with drying liquids by spraying them into a stream of hot air laid the foundation for what would later become a crucial process in various industries.

Over the years, spray drying technology has undergone numerous advancements, with each iteration pushing the boundaries of efficiency and product quality. Today, it stands as a testament to human ingenuity, widely adopted in sectors ranging from food and pharmaceuticals to chemicals and cosmetics.

Working Principle of Spray Dryers

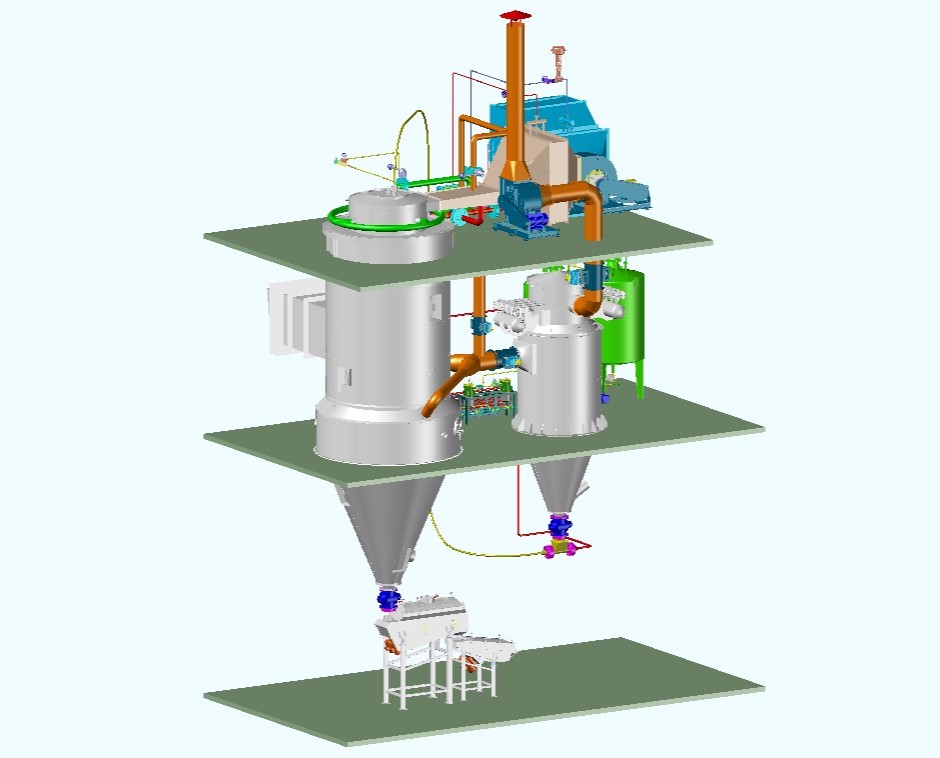

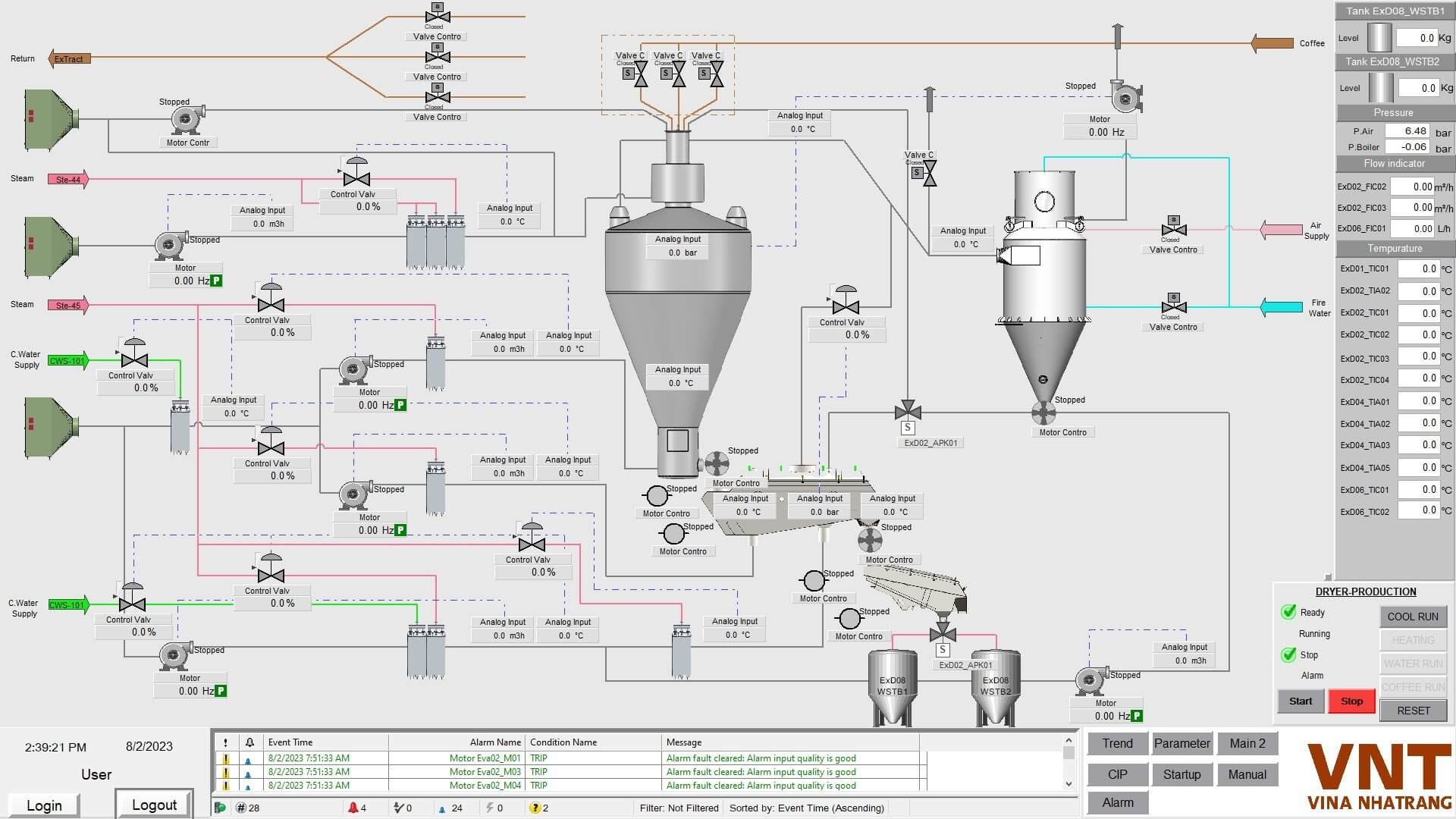

At the heart of spray drying technology lies a deceptively simple yet ingenious process. First, a liquid feed, such as a coffee extract, is atomized into a fine mist of droplets using specialized nozzles or rotary atomizers. These tiny droplets are then introduced into a hot air stream, where the rapid evaporation of moisture occurs, leaving behind a dry, powdered product.

Controlling parameters like droplet size, temperature, air velocity, and moisture content is crucial in achieving the desired product characteristics. Precise adjustments can influence factors such as particle size, density, and solubility, ensuring that the resulting instant coffee powder meets the highest quality standards.

One such advanced system that exemplifies the power of spray drying technology is VNT’s Instant Coffee Spray Dryer. This cutting-edge system combines advanced spray drying equipment with a fluid bed dryer, delivering several key benefits for coffee business owners.

Firstly, the system prioritizes quality and customization. The combination of spray drying and a low drying temperature range (160°C – 185°C) creates a gentle drying process that helps safeguard the volatile aromatic compounds responsible for the coffee’s flavor and aroma. This translates to a high-quality final product with a richer flavor profile, closer to freshly brewed coffee. Additionally, the system offers remarkable adjustability, allowing you to tailor the density (200-320 g/l) and moisture content (less than 5%) of the final coffee powder to meet your specific needs and market preferences. Some configurations might even allow you to control factors like solubility and color intensity, providing even greater customization potential.

Secondly, the integration of a fluid bed dryer contributes to an efficient drying process. Fluid bed dryers excel at handling materials with high moisture content. By working in conjunction with the spray dryer, the fluid bed dryer can potentially reduce the overall drying time and improve overall production efficiency.

With VNT’s Instant Coffee Spray Dryer, coffee business owners can leverage the power of advanced spray drying technology to deliver superior instant coffee products that meet the highest standards of quality, customization, and efficiency.

Advantages of Spray Drying in Instant Coffee Production

The benefits of spray drying in instant coffee production are multifaceted. One of the most significant advantages is the ability to produce free-flowing powders that are easy to handle, package, and dissolve in hot water. This characteristic not only enhances consumer convenience but also ensures consistent product quality.

Moreover, spray drying offers unparalleled flexibility, allowing manufacturers to tailor the process to specific coffee blends and desired flavor profiles. By carefully controlling the drying conditions, the delicate aroma and taste of the coffee can be preserved, resulting in a superior product that closely resembles freshly brewed coffee.

Compared to traditional drying methods, spray drying is highly efficient and cost-effective, reducing the risk of product contamination and minimizing waste. This not only benefits coffee manufacturers but also contributes to a more sustainable and environmentally-friendly production process.

Unleash the potential of your coffee – explore our industry-leading Instant Coffee Spray Dryers today.

Disadvantages and Challenges

While spray drying technology offers numerous advantages, it is not without its limitations. One of the primary challenges is the requirement for relatively low feed viscosity, which can restrict the range of products that can be effectively processed. Additionally, the initial capital investment and operational costs associated with spray drying systems can be substantial, particularly for smaller-scale operations.

Energy consumption is another concern, as the drying process requires significant amounts of heat, which can translate into higher production costs and a larger carbon footprint. Operational safety is also a crucial consideration, as the handling of hot air streams and fine powders demands strict adherence to safety protocols and proper equipment maintenance.

However, these challenges are not insurmountable. Advancements in spray drying technology, such as the development of energy-efficient systems and improved process monitoring and control, are paving the way for more cost-effective and sustainable operations. Furthermore, advancements in spray drying technology, such as improved process monitoring and control systems, are helping to optimize operations and mitigate potential safety risks. Careful system design and implementation of best practices can further enhance safety and efficiency.

While the initial capital investment for advanced spray drying systems like VNT’s Instant Coffee Spray Dryer may be substantial, the long-term benefits in terms of product quality, customization capabilities, and operational efficiency can significantly offset these costs, ultimately driving profitability and customer satisfaction.

Applications Beyond Instant Coffee

While the focus of this discussion has been on instant coffee production, spray drying technology has found widespread applications across various industries. In the pharmaceutical sector, it is used for the production of dry powder inhalers and encapsulation of active ingredients. The chemical industry benefits from spray drying for the production of catalysts, pigments, and specialty chemicals.

Agriculture and food processing also rely heavily on spray drying for the preservation of milk powders, egg products, and flavors. Even the cosmetics industry has embraced this technology for the production of dry powder formulations, such as blushes and eyeshadows.

The versatility of spray drying lies in its ability to process a wide range of feedstocks and tailor the process parameters to achieve desired product characteristics. This adaptability has made it an indispensable tool across multiple industries, driving innovation and efficiency.

Ready to discuss your Spray Drying needs? Contact our experts today!

Conclusion

In the realm of instant coffee production, spray drying technology has proven to be a game-changer, offering unparalleled efficiency, flexibility, and product quality. From preserving the delicate flavors and aromas of freshly brewed coffee to ensuring convenience and consistency, this innovative process has revolutionized the way we enjoy our morning cup of joe.

As the demand for instant coffee continues to grow, driven by busy lifestyles and changing consumer preferences, spray drying technology will undoubtedly play a pivotal role in meeting this demand. With ongoing research and development, we can expect to see even more advancements in areas such as energy efficiency, process control, and customization capabilities.

Whether you’re a coffee connoisseur or a business owner seeking to elevate your instant coffee offerings, understanding the intricacies of spray drying technology is essential. By embracing this innovative process, you can unlock a world of possibilities, delivering a superior product that captures the essence of freshly brewed coffee in every sip.