Introduction

Have you ever wondered how industries manage to extract valuable resources from wastewater or concentrate fruit juices without compromising their flavor? The answer lies in a fascinating process called evaporation technology. At its core, evaporation is a simple concept we’ve all observed in nature – think of puddles disappearing on a hot day. But when harnessed and refined for industrial use, this natural phenomenon becomes a powerful tool for separating liquids from solids or concentrating solutions.

Evaporation technology is the process of separating a solvent (usually water) from a solution by converting it into vapor. While this might sound straightforward, the applications and implications of this technology are far-reaching and increasingly crucial in our resource-conscious world.

Why does evaporation technology matter?

In an era where sustainable practices and efficient resource management are paramount, industries are constantly seeking ways to reduce waste, recover valuable materials, and minimize their environmental footprint. Evaporation technology offers a solution to these challenges across a wide range of sectors, from wastewater treatment and food processing to pharmaceutical manufacturing and beyond.

The key benefits of evaporation technology are threefold:

- Waste Reduction: By concentrating solutions and separating water from contaminants, evaporation significantly reduces the volume of waste that needs to be disposed of or treated further.

- Resource Recovery: Many industrial processes produce wastewater containing valuable compounds. Evaporation allows for the recovery of these materials, turning what was once considered waste into a valuable resource.

- Energy Efficiency: While traditional evaporation methods can be energy-intensive, modern techniques have dramatically improved efficiency, making the process more sustainable and cost-effective.

As we delve deeper into the world of evaporation technology, we’ll explore its various types, applications, and the innovative techniques that are revolutionizing industries. Whether you’re a professional looking to optimize your processes or simply curious about how everyday products are made, understanding evaporation technology offers fascinating insights into the invisible processes shaping our world.

What Are The Main Types of Evaporation Technology?

Evaporation technology comes in several forms, each with its own strengths and ideal applications. Let’s explore the three main types:

A. Atmospheric Evaporation

Imagine leaving a pot of water on the stove – that’s essentially atmospheric evaporation in its simplest form. In industrial settings, atmospheric evaporation uses direct heat under normal atmospheric pressure to turn a liquid into vapor.

This method is straightforward and has been used for centuries in various forms. Its simplicity makes it suitable for small-scale operations or in situations where advanced technology isn’t available. For instance, some small-scale maple syrup producers still use atmospheric evaporation to concentrate their sap.

However, there’s a catch. Atmospheric evaporation is energy-intensive, requiring a significant amount of heat to bring the liquid to its boiling point and maintain evaporation. This can lead to high energy costs and a larger carbon footprint, making it less favored for large-scale industrial applications in today’s energy-conscious world.

B. Heat Pump Vacuum Evaporation

Now, let’s add a twist to our boiling water analogy. Have you ever noticed that water boils at a lower temperature at high altitudes? Heat pump vacuum evaporation capitalizes on this principle.

By creating a vacuum, this method lowers the boiling point of the liquid being evaporated. This means less energy is required to initiate and maintain the evaporation process. But the innovation doesn’t stop there – heat pump vacuum evaporation also cleverly reuses the latent heat of condensation, further improving energy efficiency.

This method shines in low- and medium-flow water treatment applications. It’s particularly useful in industries that need to treat moderate amounts of wastewater or concentrate heat-sensitive products. For example, the dairy industry often uses vacuum evaporation to concentrate milk without risking heat damage to proteins and other nutrients.

C. Mechanical Vapor Recompression (MVR)

If heat pump vacuum evaporation is clever, then Mechanical Vapor Recompression (MVR) is a stroke of genius. This method takes energy efficiency to new heights by reusing the vapor energy for further evaporation.

Here’s how it works: The vapor produced during evaporation is compressed, which increases its temperature and pressure. This high-energy vapor is then used as a heating medium for the next round of evaporation. It’s like using the steam from your kettle to boil more water – a continuous cycle of energy reuse.

MVR is a game-changer in industries dealing with large volumes of wastewater or requiring significant concentration of products. It’s particularly popular in wastewater treatment plants, where it can dramatically reduce the volume of waste while recovering clean water. The Instant Coffee Evaporation System also often utilizes MVR technology to efficiently concentrate coffee extract.

The energy savings with MVR can be substantial. In some cases, it can reduce energy consumption by up to 95% compared to traditional evaporation methods. This not only cuts operational costs but also significantly reduces the carbon footprint of industrial processes.

As we move forward, keep these three types of evaporation technology in mind. Their unique characteristics play a crucial role in determining their suitability for different applications, which we’ll explore in the next section.

Applications of Evaporation Technology

Evaporation technology isn’t just a one-trick pony – it’s a versatile workhorse with applications across a wide range of industries. Let’s dive into some of the key areas where this technology is making a significant impact:

How Is Evaporation Used in Wastewater Treatment?

Picture this: a mining operation produces thousands of gallons of wastewater daily, filled with dissolved metals and other contaminants. How do you deal with such a vast amount of potentially harmful liquid? Enter evaporation technology.

In wastewater treatment, evaporation serves two crucial purposes:

- Volume Reduction: By evaporating water from the waste stream, the overall volume of wastewater is significantly reduced. This makes subsequent treatment or disposal much more manageable and cost-effective.

- Resource Recovery: Many industrial wastewaters contain valuable dissolved solids. Evaporation allows for the concentration and recovery of these materials, turning waste into a potential revenue stream.

Case studies across various industries highlight the power of evaporation in wastewater treatment:

- In the mining industry, evaporators are used to treat acid mine drainage, concentrating metal contaminants for easier disposal or recovery.

- Oil and gas operations use evaporation to deal with produced water, reducing disposal costs and recovering valuable minerals.

- Municipal waste management facilities employ evaporation to concentrate leachate from landfills, making it easier to treat and dispose of safely.

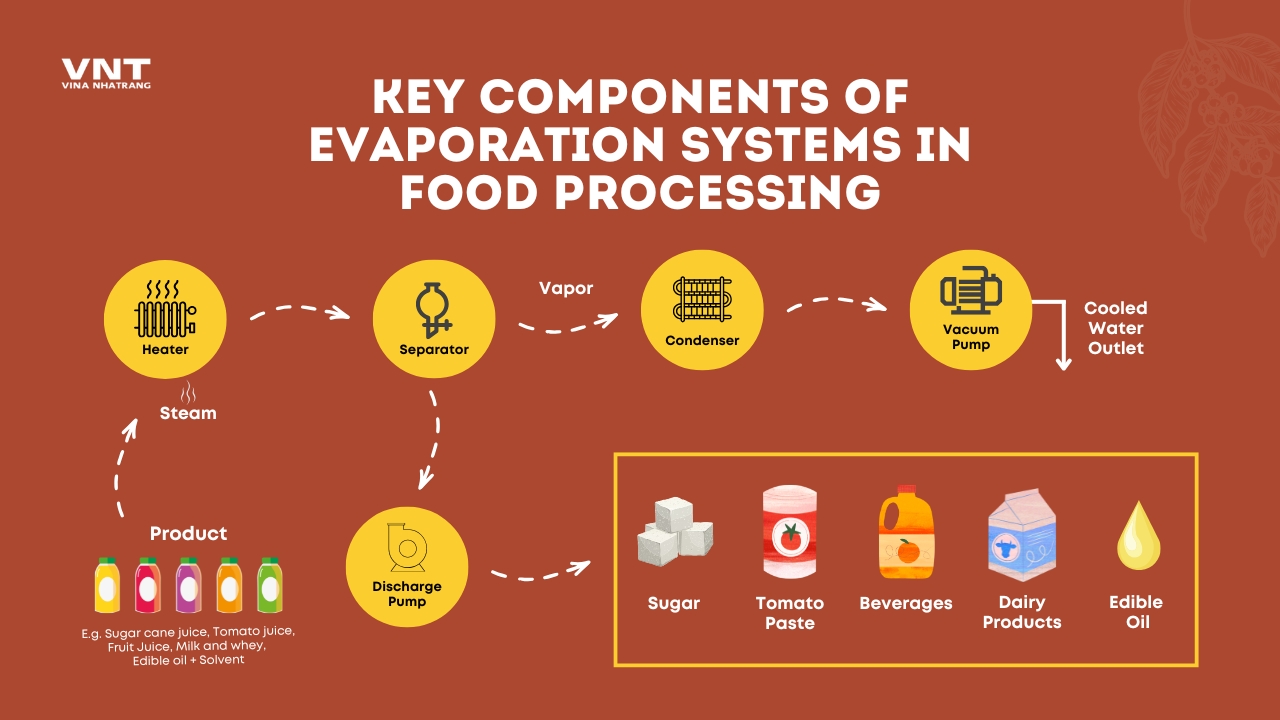

How Is Evaporation Used in Food and Beverage Industry?

Have you ever wondered how concentrated fruit juices are made, or how milk is turned into powdered form? Evaporation technology plays a starring role in these processes.

In the food and beverage industry, evaporation is used primarily for concentration. This serves several purposes:

- Preservation: By removing water, products become less susceptible to bacterial growth, extending shelf life.

- Flavor Enhancement: Concentrating certain products can intensify flavors, a technique used in everything from tomato paste to maple syrup.

- Transportation Efficiency: Concentrated products are lighter and take up less space, reducing transportation costs.

Examples of evaporation technology in food processing include:

- Juice Concentration: Fruit juices are evaporated to remove water, creating concentrated products that can be easily transported and reconstituted later.

- Dairy Processing: Milk is evaporated to create condensed milk, or further processed into powdered milk.

- Sugar Production: Sugar cane juice is evaporated to crystallize sugar.

The Instant Coffee Evaporation System is another prime example, where coffee extract is concentrated to create instant coffee powder.

Explore more: What is Evaporation Technology in Food Processing?

How Is Evaporation Used in Chemical and Pharmaceutical Sectors?

In the world of chemicals and pharmaceuticals, purity is paramount. Evaporation technology plays a crucial role in achieving the high levels of purity required in these industries.

Here’s how evaporation contributes:

- Concentration of Non-volatile Solutes: By evaporating the solvent (often water), the desired non-volatile compounds are concentrated. This is particularly useful in the production of pharmaceuticals where active ingredients need to be concentrated.

- Separation of Mixtures: Evaporation can be used to separate compounds with different boiling points, a technique known as fractional distillation.

- Crystallization: In some cases, evaporation is used to supersaturate a solution, leading to the formation of crystals. This is common in the production of certain pharmaceuticals and fine chemicals.

The use of energy-efficient methods like Mechanical Vapor Recompression (MVR) is particularly important in these sectors. The high volumes and energy-intensive nature of many chemical processes mean that even small improvements in efficiency can lead to significant cost savings and reduced environmental impact.

For instance, in the production of common chemicals like caustic soda or hydrochloric acid, MVR evaporators are used to concentrate the solutions efficiently. In pharmaceutical manufacturing, gentle evaporation techniques are employed to concentrate heat-sensitive compounds without degradation.

As we can see, evaporation technology is a versatile tool, adaptable to a wide range of industrial needs. From treating wastewater to creating the foods we eat and the medicines we rely on, this technology plays a hidden but crucial role in many aspects of our daily lives.

In the next section, we’ll explore some of the more advanced evaporation techniques that are pushing the boundaries of what’s possible in industrial processing. These innovations are not only improving efficiency but also opening up new possibilities for resource recovery and waste reduction.

What Are the Advanced Evaporation Techniques?

As industries strive for greater efficiency and sustainability, evaporation technology has evolved to meet these demands. Two advanced techniques stand out for their innovative approaches to enhancing the evaporation process: Multiple-Effect Distillation (MED) and Crystallization with Evaporation.

A. Multiple-Effect Distillation (MED)

Imagine a domino effect, but instead of falling tiles, we’re talking about cascading energy use. That’s essentially what Multiple-Effect Distillation (MED) achieves in the world of evaporation technology.

How MED Works:

- The process begins with steam being introduced to the first “effect” or stage of the evaporator.

- This steam causes the liquid in the first effect to boil and partially evaporate.

- The vapor produced in this first effect then becomes the heating medium for the second effect, which operates at a lower pressure and temperature.

- This process continues through multiple effects, each at a lower pressure and temperature than the last.

The brilliance of MED lies in its energy efficiency. By reusing the vapor from each effect to drive the next, it dramatically reduces the overall energy input required. To put this into perspective, let’s compare the energy consumption:

- Single-effect evaporation typically requires about 1 kg of steam to evaporate 1 kg of water.

- A triple-effect MED system can evaporate up to 3 kg of water using the same 1 kg of steam.

- Advanced MED systems with 6 or more effects can achieve even higher ratios, sometimes evaporating up to 8-10 kg of water per kg of steam.

This efficiency makes MED particularly valuable in industries dealing with large volumes of liquid, such as desalination plants or large-scale wastewater treatment facilities. It’s also widely used in the food industry, especially in the production of concentrated fruit juices and dairy products.

B. Crystallization with Evaporation

Now, let’s add another layer of complexity to our evaporation process. What if, instead of just concentrating a solution, we could extract solid crystals from it? That’s exactly what Crystallization with Evaporation achieves.

This technique is particularly valuable when dealing with wastewater or process streams that contain dissolved salts or other crystallizable compounds. Here’s how it works:

- The solution is evaporated until it becomes supersaturated with the dissolved compound.

- As evaporation continues, the compound begins to crystallize out of the solution.

- These crystals are then separated from the remaining liquid, often through centrifugation or filtration.

The beauty of this process is that it not only reduces the volume of waste but also recovers valuable materials that would otherwise be lost. Some examples of where this technique shines include:

- Recovery of valuable salts from industrial brines

- Extraction of minerals from mining wastewater

- Production of high-purity chemicals in the pharmaceutical industry

For instance, in the treatment of produced water from oil and gas operations, crystallization with evaporation can recover salts like sodium chloride and calcium chloride, which have commercial value. In the chemical industry, it’s used to produce high-purity compounds like sodium sulfate or potassium nitrate.

The Instant Coffee Evaporation System often incorporates crystallization in its final stages to produce instant coffee granules or powder.

These advanced techniques represent the cutting edge of evaporation technology. They push the boundaries of efficiency and resource recovery, turning what was once considered waste into valuable products. As we move towards a more circular economy, technologies like MED and Crystallization with Evaporation will play an increasingly important role in maximizing the value we extract from our resources while minimizing waste.

In the next section, we’ll explore the environmental and economic benefits that these advanced evaporation technologies bring to various industries.

What Are The Environmental and Economic Benefits of Evaporation Technology

As we’ve journeyed through the world of evaporation technology, you’ve probably started to see glimpses of its potential to revolutionize industrial processes. Now, let’s zoom out and look at the bigger picture – the substantial environmental and economic benefits that advanced evaporation technologies bring to the table.

A. Energy Efficiency

In today’s world, energy efficiency isn’t just a buzzword – it’s a necessity. Both for the bottom line of businesses and the health of our planet. This is where advanced evaporation technologies truly shine.

Let’s compare the energy consumption of various evaporation methods:

- Atmospheric Evaporation: This traditional method typically requires about 1 kWh of energy to evaporate 1 kg of water. It’s simple but energy-hungry.

- Vacuum Evaporation: By lowering the boiling point, this method reduces energy consumption to about 0.3-0.5 kWh per kg of water evaporated.

- Mechanical Vapor Recompression (MVR): Here’s where things get impressive. MVR systems can evaporate 1 kg of water using just 0.01-0.02 kWh of energy. That’s a 98% reduction compared to atmospheric evaporation!

- Multiple-Effect Distillation (MED): While not as efficient as MVR for smaller systems, MED shines in large-scale operations. A 6-effect MED system can achieve energy consumption as low as 0.007 kWh per kg of water evaporated.

These efficiency gains translate directly into reduced energy costs and lower carbon emissions. For instance, a medium-sized industrial plant switching from atmospheric to MVR evaporation could potentially reduce its carbon footprint by hundreds of tons of CO2 per year – equivalent to taking dozens of cars off the road.

B. Resource Recovery

One person’s trash is another person’s treasure – and nowhere is this truer than in the world of advanced evaporation technology. These systems are turning waste streams into valuable resources, creating new revenue streams and reducing disposal costs.

Here are some examples of resource recovery through evaporation:

- Water Recovery: In many industries, the primary “product” of evaporation is pure water. This recovered water can often be reused in industrial processes, reducing freshwater consumption. In water-scarce regions, this can be a game-changer.

- Salt Recovery: Industries like oil and gas production often produce brines rich in various salts. Evaporation and crystallization can recover these salts for commercial use. For instance, sodium chloride recovered from desalination brine can be sold for industrial or even food-grade applications.

- Metal Recovery: In mining and metal finishing industries, evaporation can concentrate metal-rich wastewater, facilitating the recovery of valuable metals like copper, nickel, or precious metals.

- Organic Compound Recovery: In the food and beverage industry, evaporation is used to recover and concentrate valuable organic compounds. The Instant Coffee Evaporation System, for example, recovers and concentrates coffee solids, turning them into instant coffee products.

The economic impact of resource recovery can be substantial. What was once a cost center (waste disposal) becomes a potential profit center. Moreover, by reducing waste volumes, companies can significantly cut their disposal costs.

C. Regulatory Compliance and Sustainability

In an era of increasingly stringent environmental regulations, advanced evaporation technologies offer a path to compliance while improving sustainability.

- Zero Liquid Discharge (ZLD): Many industries are moving towards ZLD systems, where all wastewater is treated and reused, with no liquid leaving the facility. Advanced evaporation and crystallization technologies are key components of ZLD systems.

- Reduced Contamination Risk: By reducing the volume of waste and recovering valuable components, evaporation technologies minimize the risk of environmental contamination. This is particularly crucial in industries dealing with hazardous materials.

- Water Conservation: In many regions, water scarcity is a growing concern. Evaporation technologies that allow for water recovery and reuse can help industries reduce their freshwater consumption, aligning with water conservation regulations and sustainability goals.

- Carbon Footprint Reduction: The energy efficiency of advanced evaporation technologies directly translates to reduced carbon emissions. This helps companies meet carbon reduction targets and potentially benefit from carbon credit systems in some regions.

- Circular Economy: By facilitating resource recovery, evaporation technologies support the transition to a circular economy model. This aligns with sustainability initiatives and can improve a company’s environmental, social, and governance (ESG) profile.

For example, a textile manufacturer implementing an MVR evaporation system for dyehouse wastewater treatment could potentially recover 95% of the water for reuse, significantly reduce its chemical oxygen demand (COD) discharge, and recover valuable dyes and salts. This not only ensures compliance with wastewater discharge regulations but also improves the company’s sustainability metrics and potentially opens new revenue streams from recovered materials.

The economic benefits of improved regulatory compliance shouldn’t be underestimated. By proactively adopting advanced evaporation technologies, companies can avoid costly fines, reduce the risk of forced shutdowns, and potentially gain preferential treatment in permitting processes for future expansions.

Moreover, as consumers become increasingly environmentally conscious, companies that can demonstrate strong sustainability practices often enjoy improved brand reputation and customer loyalty. The adoption of advanced evaporation technologies can be a key part of this sustainability story.

In essence, the environmental and economic benefits of advanced evaporation technologies are deeply intertwined. Energy efficiency leads to cost savings and reduced emissions. Resource recovery turns waste into value. And improved sustainability practices support regulatory compliance while enhancing brand value.

As we move forward, it’s clear that evaporation technology will play an increasingly crucial role in helping industries balance economic growth with environmental stewardship. However, like any technology, it comes with its own set of challenges and opportunities for innovation. In the next section, we’ll explore these challenges and the cutting-edge innovations that are shaping the future of evaporation technology.

What Are The Challenges and Innovations in Evaporation Technology?

While evaporation technology offers numerous benefits, it’s not without its challenges. However, as is often the case in the world of technology, these challenges have spurred innovations that are pushing the boundaries of what’s possible. Let’s explore both the hurdles and the exciting developments in this field.

A. High Capital Costs

One of the primary challenges in implementing advanced evaporation systems is the initial investment required. High-efficiency systems like multiple-effect evaporators and MVR units come with significant upfront costs.

Challenge:

- The capital expenditure for a large-scale MVR or multiple-effect evaporation system can run into millions of dollars.

- This high initial cost can be a barrier, especially for smaller companies or those in industries with tight profit margins.

However, it’s crucial to view these costs in the context of long-term savings and benefits. Let’s consider an example:

A medium-sized food processing plant decides to invest in an MVR evaporation system costing $2 million. While this seems steep, the system:

- Reduces energy consumption by 85% compared to their old atmospheric evaporator

- Allows for 90% water recovery, significantly cutting water costs

- Improves product quality, leading to increased sales

In this scenario, the payback period could be as short as 2-3 years, after which the system continues to provide savings and benefits for its operational life, typically 20+ years.

Innovations addressing this challenge:

- Modular Systems: Some manufacturers now offer modular evaporation units. These can be scaled up over time, allowing companies to spread the capital cost over a longer period.

- Hybrid Financing Models: Innovative financing options are emerging, such as “evaporation-as-a-service” models, where the technology provider installs and operates the system, charging the client based on volume treated or resources recovered.

- Performance Guarantees: To mitigate risk, some suppliers now offer performance guarantees, ensuring that the system will deliver specified efficiency improvements or resource recovery rates.

B. Recent Innovations

The field of evaporation technology is far from stagnant. Researchers and engineers are constantly pushing the envelope, developing new techniques and improving existing ones. Here are some of the most exciting recent innovations:

- Smart Evaporation Systems: The integration of Internet of Things (IoT) technology and artificial intelligence is revolutionizing evaporation systems. These smart systems can:

- Continuously optimize operating parameters based on real-time data

- Predict maintenance needs, reducing downtime

- Adapt to changing input conditions automatically

For instance, a smart Instant Coffee Evaporation System might adjust its operation based on the specific characteristics of each batch of coffee extract, ensuring consistent quality while maximizing energy efficiency.

- Advanced Materials: New, corrosion-resistant materials are expanding the applications of evaporation technology:

- Graphene-based membranes show promise for desalination and wastewater treatment

- Advanced polymers and alloys are improving heat transfer efficiency and extending equipment life

- Hybrid Systems: Combining evaporation with other separation technologies is opening new possibilities:

- Membrane distillation-evaporation hybrids are showing promise for treating high-salinity wastewater

- Evaporation-reverse osmosis combinations are improving efficiency in desalination plants

- Enhanced Heat Transfer Techniques: Innovations in heat transfer are boosting the efficiency of evaporation systems:

- Nanofluids as heat transfer media are showing potential for improved thermal conductivity

- Advanced heat exchanger designs, like printed circuit heat exchangers, are dramatically improving heat transfer efficiency

- Renewable Energy Integration: Coupling evaporation systems with renewable energy sources is reducing their carbon footprint:

- Solar-powered evaporation systems are being developed for small-scale desalination in remote areas

- Waste heat from other industrial processes is being harnessed to drive evaporation, improving overall plant efficiency

- Zero Liquid Discharge (ZLD) Innovations: Advancements in ZLD systems are making this once-costly approach more accessible:

- New crystallizer designs are improving salt recovery and reducing energy consumption

- Electrodialysis reversal (EDR) is being integrated into evaporation-based ZLD systems to reduce scaling and improve water recovery

These innovations are not just theoretical – they’re already being implemented in various industries. For example, a large automotive manufacturer recently implemented a smart MVR evaporation system for treating their paint shop wastewater. The system uses AI to continuously optimize its operation based on wastewater composition, resulting in a 30% improvement in energy efficiency compared to their previous system.

As these technologies mature and become more widely adopted, we can expect to see evaporation playing an even more crucial role in industrial water management and resource recovery. The challenges of high capital costs and energy consumption are being steadily addressed, opening up new possibilities for sustainable industrial practices.

In our final section, we’ll recap the key points we’ve covered and look ahead to the future of evaporation technology.

Conclusion

As we’ve journeyed through the world of evaporation technology, we’ve seen how this seemingly simple process – the transformation of liquid into vapor – has evolved into a sophisticated suite of technologies with far-reaching implications for industry and the environment.

Let’s recap the key benefits of evaporation technology:

- Waste Reduction: By concentrating waste streams, evaporation dramatically reduces the volume of material that needs to be treated or disposed of. This not only cuts costs but also minimizes environmental impact.

- Resource Recovery: From water to valuable minerals and organic compounds, evaporation technology is turning waste streams into resources. This aligns perfectly with the principles of a circular economy, where waste is minimized and materials are kept in use for as long as possible.

- Energy Efficiency: Advanced evaporation technologies like MVR and MED have pushed the boundaries of energy efficiency. By cleverly reusing heat and operating under optimized conditions, these systems can achieve remarkable energy savings compared to traditional methods.

- Versatility: From the Instant Coffee Evaporation System concentrating your morning brew to industrial-scale wastewater treatment plants, evaporation technology finds applications across a wide range of industries and scales.

- Sustainability: By reducing waste, recovering resources, and improving energy efficiency, evaporation technology is playing a crucial role in making industrial processes more sustainable and environmentally friendly.

As we look to the future, the trajectory of evaporation technology is clear – it will become increasingly intelligent, efficient, and integrated with other processes. The advent of smart, AI-driven systems promises to optimize operations in real-time, while new materials and heat transfer techniques will push the boundaries of what’s possible in terms of efficiency and application range.

The integration of renewable energy sources with evaporation systems opens up exciting possibilities for sustainable water treatment and desalination, potentially addressing water scarcity issues in many parts of the world. Meanwhile, the trend towards zero liquid discharge systems, driven by both regulatory pressures and sustainability goals, will likely see evaporation technology playing an even more central role in industrial water management.

However, challenges remain. The high capital costs of advanced systems continue to be a barrier for some industries, particularly smaller operations. Innovative financing models and the development of more affordable, modular systems will be crucial in making these technologies more accessible.

As we conclude, it’s worth reflecting on the broader implications of these technological advancements. Evaporation technology is more than just an industrial process – it’s a key enabler of more sustainable, circular industrial practices. By allowing us to recover and reuse resources that would otherwise be wasted, it’s helping to reshape our relationship with waste and resource consumption.

For professionals working in industries where water management and resource recovery are crucial, staying abreast of developments in evaporation technology is essential. Whether you’re in food processing, chemical manufacturing, mining, or wastewater treatment, the innovations in this field could offer solutions to some of your most pressing challenges.

For the broader public, understanding technologies like evaporation gives us insight into the often-invisible processes that shape our world. From the coffee we drink to the clothes we wear, evaporation technology plays a role in countless products and processes we encounter daily.

As we face growing environmental challenges and resource constraints, technologies that allow us to do more with less will become increasingly important. Evaporation technology, with its ability to recover resources and reduce waste, is poised to play a crucial role in this more sustainable future.

The story of evaporation technology is far from over. As research continues and new applications emerge, we can expect to see this ancient process continue to evolve, driving us towards a more efficient, sustainable, and circular industrial future. Whether you’re a industry professional looking to optimize your processes or simply curious about the technologies shaping our world, keeping an eye on developments in evaporation technology promises to be a fascinating journey.