In the world of commercial coffee brewing, achieving consistent and high-quality grinds is paramount. Industrial coffee grinders are the workhorses that make this possible, especially for large-scale operations processing 60 to 120 kilograms of coffee beans at a time. Understanding how these behemoth grinders work can help coffee professionals optimize flavor extraction and deliver a superior brew every time.

Types of Industrial Coffee Grinders

Industrial coffee grinders can be broadly classified into two types: burr grinders and blade grinders.

- Burr Grinders: Burr grinders are the preferred choice for commercial and industrial applications. They come in two varieties:

- a. Conical Burr Grinders: These grinders feature two cone-shaped burrs that crush the coffee beans between them.

- b. Flat Burr Grinders: These grinders use two flat, circular burrs to grind the coffee beans.

- Blade Grinders: Blade grinders, while more common in household settings, are sometimes used in industrial settings as well. They use spinning blades to chop the coffee beans into smaller pieces.

While burr grinders and blade grinders are the most common, there are other varieties worth considering, such as Doser Grinders, Doserless Grinders, and Stepless Grinders.

Find out more about these types and their suitability for your operations in our comprehensive blog post: Types of Industrial Coffee Grinders: A Comprehensive Guide.

How Burr Grinders Work?

Burr grinders are the industry standard for industrial coffee grinding due to their ability to produce consistent and uniform grinds.

1. Principle of Operation

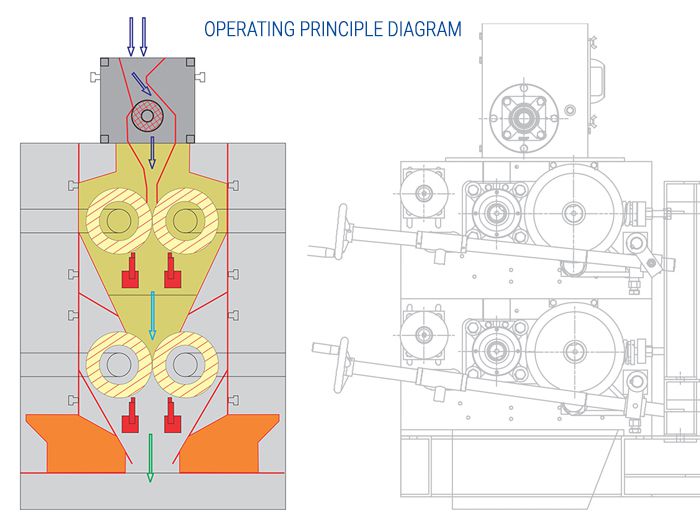

At the heart of burr grinders lies a sophisticated grinding mechanism that ensures unmatched precision and grind quality. These grinders work by crushing coffee beans between two burrs – meticulously engineered grinding stones crafted from durable materials like steel or ceramic. The burrs are precisely machined to exacting tolerances, enabling them to grind the beans into a remarkably fine and consistent particle size. This uniform grind consistency is crucial for achieving optimal flavor extraction and a balanced, rich taste in the final brew.

The grinding process is a result of the carefully calibrated distance between the two burrs and their rotational speed. As the beans pass through the narrow gap between the burrs, they are subjected to immense pressure and shearing forces, effectively fracturing them into uniform particles. This precise grinding action ensures that each coffee particle is exposed to the brewing water in a consistent manner, allowing for even extraction and the full expression of the coffee’s aroma and flavor notes.

2. Grinding Process

- Loading the Hopper: Industrial burr grinders are built to handle big amounts of coffee beans, usually between 60 to 120 kilograms. First, carefully pour these large amounts of whole beans into the hopper, which is a big container at the top of the grinder.

- Calibrating the Grind Settings: Precision is really important in industrial coffee grinding. These strong machines let you control the size of the grind precisely, so you get the same results every time, depending on how you’re brewing your coffee or what flavor you want.

- Stepped Adjustments: Many industrial grinders have set grind sizes you can choose from, for different brewing methods. You can pick from fine espresso grinds to coarser drip coffee grounds.

- Stepless Adjustments: Some high-end industrial grinders have a mechanism that lets you adjust the grind size with even more precision, giving you a lot of different options. This means coffee pros can get exactly the right grind they need, unlocking the full flavor of the coffee beans.

- High-Powered Grinding: Once you’ve set the grind size you want, the industrial grinding starts. The burrs, which are the parts that crush the beans, spin really fast because of strong motors. This powerful grinding, along with the well-made burrs, makes sure the coffee grounds are all the same size.

- Efficient Collection: After grinding, the coffee grounds are smoothly poured into big catch bins or containers. These containers are made to hold a lot of coffee grounds, so you can keep grinding without stopping and easily process a lot of coffee at once.

With every step designed for making a lot of coffee, industrial burr grinders show the perfect balance of power, precision, and efficiency. They give you consistent, high-quality coffee grounds, which are essential for making great coffee on an industrial scale.

3. Advantages of Burr Grinders

- Consistent grind size: Burr grinders produce uniform grinds, ensuring even extraction and optimal flavor.

- Better flavor extraction: The consistent grind size allows for better extraction of the coffee’s natural flavors and aromas.

- Adjustable grind settings: The ability to adjust the grind size makes burr grinders suitable for various brewing methods, from espresso to drip coffee.

How Blade Grinders Work?

While burr grinders are the industry standard for commercial and industrial applications, blade grinders offer a unique approach to coffee grinding that is worth exploring, especially for smaller-scale operations or specific brewing requirements.

1. Principle of Operation

Unlike burr grinders, which rely on precise grinding stones, blade grinders employ a different mechanism to break down coffee beans. At the heart of these grinders lies a set of sharp, rotating blades that slice and chop the beans into smaller pieces through a cutting action.

2. Grinding Process

- Bean Loading: The process begins by introducing whole coffee beans into the grinding chamber, a specially designed compartment that houses the blade mechanism.

- High-Speed Blade Action: Once the chamber is loaded, the grinding process is initiated by activating the blades. These blades spin at remarkably high speeds, generating powerful centrifugal forces that propel the beans towards the sharp edges. As the beans come into contact with the rapidly spinning blades, they are sliced and chopped into smaller pieces through a combination of cutting and impact forces.

- Continuous Grinding Cycle: Unlike burr grinders, which typically produce a uniform grind in a single pass, blade grinders operate in a continuous cycle. The blades constantly chop and re-chop the coffee particles, gradually reducing their size until the desired grind consistency is achieved. This process requires careful monitoring and adjustments to the grinding time to prevent over-grinding or under-grinding the beans.

- Grounds Collection: After the desired grind level is reached, the freshly ground coffee is collected from the grinding chamber, ready for brewing or further processing.

While blade grinders may not offer the same level of grind consistency as burr grinders, they can still produce acceptable results for certain brewing methods or applications where absolute uniformity is less critical. Their simplicity, affordability, and ease of use make them a viable option for smaller coffee shops, cafés, or home brewing enthusiasts with modest volume requirements.

Comparison of Burr and Blade Grinders

- Grind consistency: Burr grinders produce more consistent and uniform grinds, while blade grinders can result in uneven particle sizes.

- Flavor profile: The consistent grind size from burr grinders allows for better flavor extraction and a more balanced taste.

- Suitability for different brewing methods: Burr grinders are versatile and can be used for various brewing methods, while blade grinders may not be suitable for methods that require precise grind sizes.

Explore more: Burr vs Blade Industrial Coffee Grinders: A Comprehensive Comparison.

Maintenance and Cleaning:

Regular cleaning and maintenance are essential for ensuring optimal performance and longevity of industrial coffee grinders.

- Importance of regular cleaning: Accumulated coffee residue can affect grind quality and flavor.

- Cleaning methods for burr grinders: Disassembling the burrs, brushing away residue, and using grinder cleaning tablets or solutions.

- Cleaning methods for blade grinders: Wiping down the blades and grinding chamber with a damp cloth or brush.

Contact our experts to get a consultation on choosing the best Industrial Coffee Grinder that fits you business needs.

Conclusion

Industrial coffee grinders play a vital role in the coffee industry, ensuring consistent and high-quality grinds for optimal flavor extraction and brewing results. Burr grinders, with their precise grinding mechanism and adjustable settings, are the preferred choice for commercial and industrial applications. By understanding how these grinders work, coffee professionals can make informed decisions and achieve the perfect cup of coffee every time.