Spray Drying Method

The insatiable demand for instant coffee continues to surge, driven by consumers seeking convenience without compromising on taste. As a business owner in the coffee industry, staying ahead of the curve means mastering the art of instant coffee production – and the spray drying method is at the forefront of this endeavor. In this comprehensive guide, we delve into the intricacies of the spray drying method, exploring its applications, advantages, and the cutting-edge science behind creating an instant coffee product that captivates taste buds worldwide. Whether you’re a seasoned veteran or a newcomer to the industry, this guide promises to equip you with the knowledge and insights necessary to elevate your instant coffee offerings, ensuring customer satisfaction and business growth.

Understanding Spray Drying Method

What is Spray Drying?

Spray drying is a versatile process used across various industries, notably in the production of instant coffee. It involves atomizing a liquid into fine droplets, which are then rapidly dried by hot air, resulting in a powdered product. This method is particularly favored for its efficiency and ability to preserve the flavor, aroma, and color of the original coffee extract.

How Does Spray Drying Work?

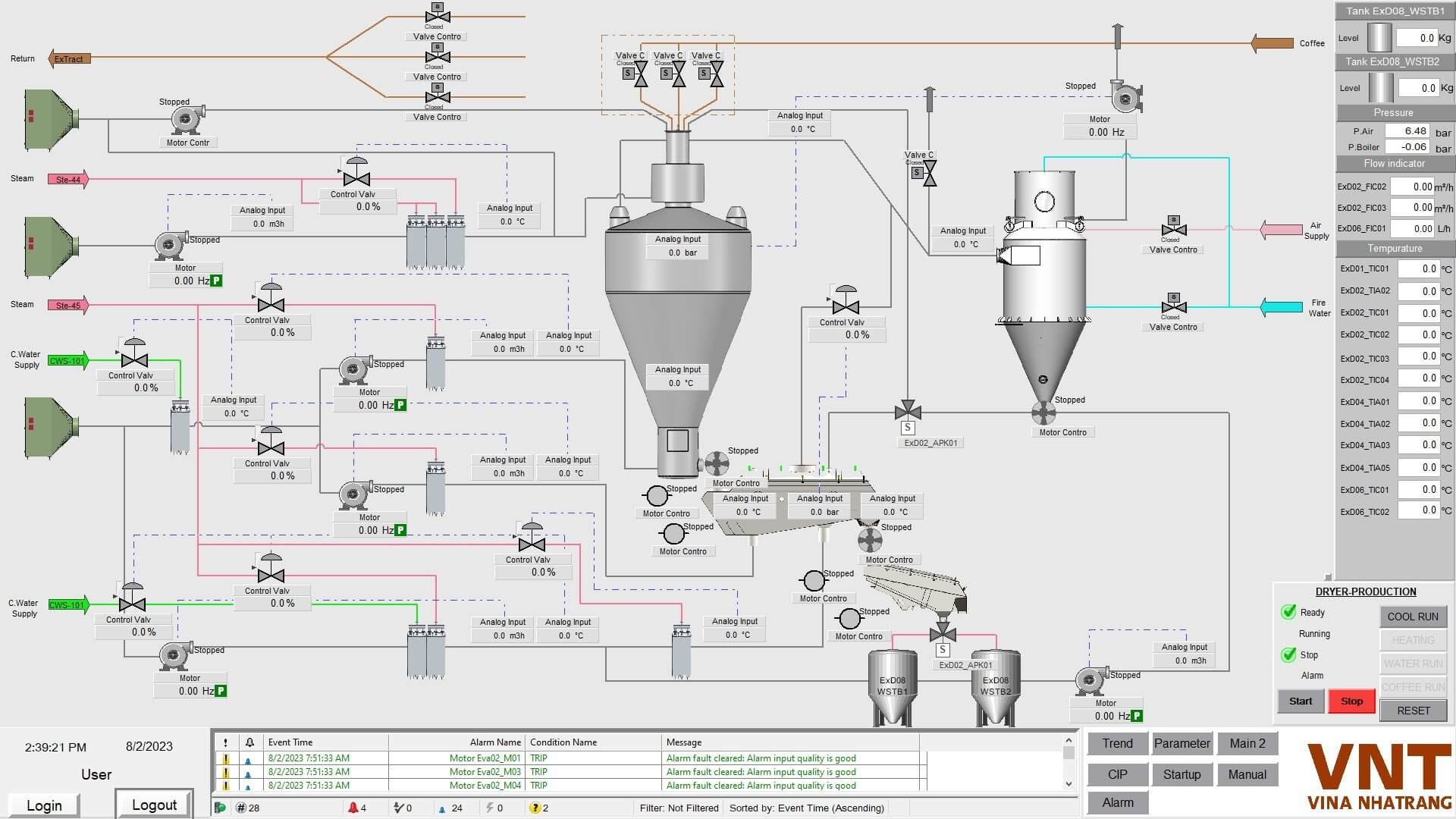

The spray drying method is a sophisticated process that involves several precisely controlled stages, each crucial for transforming liquid coffee into a high-quality instant powder. Here’s a breakdown of the critical steps:

- Feed Preparation: The journey begins with meticulously preparing the liquid coffee concentrate. This step involves carefully adjusting the concentrate’s viscosity and ensuring homogeneity, as these factors directly impact the efficiency and uniformity of the drying process.

- Atomization: Once the feed is prepared, it’s time for atomization – the heart of the spray drying process. The liquid concentrate is forced through specialized nozzles or spun at high speeds in a centrifugal atomizer, creating a fine mist of tiny droplets. This maximizes the surface area exposed to the drying air, enabling rapid and efficient moisture removal.

- Drying: The atomized droplets then enter the drying chamber, a precisely controlled environment where the real magic happens. Heated air, typically ranging from 160°C – 185°C, envelops the droplets, rapidly evaporating the moisture while preserving the coffee’s delicate flavor and aroma. This stage is meticulously monitored to ensure optimal drying conditions.

- Collection: As the drying process nears completion, the dried coffee particles are collected using specialized equipment such as cyclones or bag filters. These systems efficiently separate the fine powder from the exhaust air, ensuring a high-quality, consistent product ready for packaging or further processing.

Each stage of the spray drying method is carefully engineered and monitored, ensuring that the final instant coffee powder retains its rich flavor, aroma, and solubility, while offering unparalleled convenience to consumers worldwide.

For coffee businesses seeking a cutting-edge spray drying solution, the VNT’s Instant Coffee Spray Dryer stands out as a cornerstone technology that combines advanced spray drying technology with a fluid bed dryer. Discover how VNT’s Instant Coffee Spray Dryer can give your business a competitive edge HERE.

Applications Beyond Coffee

While the spray drying method is renowned for its critical role in instant coffee production, its applications extend far beyond the realm of coffee. This versatile technology has found widespread adoption across numerous industries, underscoring its adaptability and economic viability.

In the food industry, spray drying is extensively used for producing a wide range of powdered products. From milk powders and infant formula to egg powders and flavoring agents, this method ensures prolonged shelf life while preserving the nutritional integrity and sensory qualities of the original ingredients. The pharmaceutical sector also leverages the power of spray drying for the production of various drug formulations. By converting liquid medications into powdered form, this process enhances stability, improves solubility, and facilitates easier administration, benefiting both patients and healthcare providers.

Moreover, the chemical industry employs spray drying for the production of diverse products, including detergents, pigments, and even catalysts used in various chemical processes. The ability to control particle size and morphology through spray drying enables the creation of tailored products with specific properties. Agriculture is another domain where spray drying finds practical applications. This technology is utilized in the production of certain types of fertilizers and pesticides, ensuring efficient delivery and extended shelf life for these essential agricultural inputs.

Beyond these industries, spray drying has also found applications in ceramics, biotechnology, and even waste treatment processes, showcasing its remarkable versatility and adaptability.

The widespread adoption of spray drying across such diverse sectors is a testament to its economic viability and the numerous advantages it offers. As industries continually seek efficient and cost-effective manufacturing processes, the spray drying method remains a pivotal technology, driving innovation and enabling the production of high-quality products that meet the ever-evolving demands of consumers and industries alike.

Advantages of Spray Drying

The widespread adoption of the spray drying method across multiple industries can be attributed to its numerous advantages, making it a preferred choice for many manufacturers seeking efficiency, quality, and versatility in their production processes.

- Efficiency: One of the primary advantages of spray drying is its remarkable efficiency. By converting liquids to powders in a single, continuous process, it streamlines production, saving valuable time and resources. This efficiency translates into cost savings and increased productivity, enabling manufacturers to meet growing market demands effectively.

- Quality Control: Precise control over critical product parameters is essential for consistent quality, and spray drying excels in this aspect. The process allows for meticulous regulation of factors such as particle size, morphology, and residual moisture content. This level of control ensures that the final powdered product meets exacting specifications, guaranteeing uniformity and quality from batch to batch.

- Flexibility: The spray drying method is remarkably versatile, making it suitable for a wide range of products across various industries. From food ingredients and pharmaceuticals to chemicals and agrochemicals, this technology can be adapted to handle diverse materials, enabling manufacturers to expand their product portfolios and cater to diverse market needs.

- Preservation: In the context of instant coffee production, one of the key advantages of spray drying is its ability to preserve the delicate flavor, aroma, and color of the original coffee extract. The rapid drying process minimizes exposure to heat and oxidation, ensuring that the final powdered product retains the authentic taste and sensory qualities that coffee lovers crave.

- Ease of Handling and Storage: Powdered products resulting from the spray drying process are typically easier to handle, transport, and store compared to their liquid counterparts. This not only reduces the risk of spoilage or contamination but also simplifies logistics and distribution, benefiting both manufacturers and consumers.

With its numerous advantages, the spray drying method has solidified its position as a crucial technology in various industries, enabling efficient production, consistent quality, and the creation of innovative products that meet the ever-evolving demands of consumers worldwide.

Challenges and Considerations

While the spray drying method offers numerous advantages, it is not without its challenges and considerations. Addressing these factors is crucial to ensure the successful implementation of this technology and the production of high-quality powdered products.

- Thermal Degradation: One of the primary concerns in spray drying is the potential for thermal degradation. The high temperatures employed in the drying process can lead to molecular breakdown, affecting the product’s solubility, stability, and, in the case of food products like instant coffee, potentially compromising the flavor and aroma. This issue is particularly relevant for heat-sensitive materials, such as certain pharmaceuticals or delicate food ingredients.

- Stickiness and Fouling: Certain materials, particularly those with high sugar or fat content, can exhibit stickiness during the drying process. This stickiness can lead to fouling, where the product adheres to the walls of the drying chamber or equipment, causing operational issues and potential contamination.

- Particle Agglomeration: In some cases, the dried particles may agglomerate or form clusters, affecting the powder’s flow properties and potentially leading to issues during subsequent processing or packaging stages.

- Energy Consumption: Spray drying is an energy-intensive process due to the high temperatures required for drying. Optimizing energy efficiency is crucial to minimize operational costs and reduce the environmental impact associated with the process.

Despite these challenges, the spray drying method remains a highly sought-after technology due to its numerous benefits. Addressing these considerations requires careful planning, process optimization, and the implementation of appropriate strategies.

- Mitigating thermal degradation can involve adjusting drying temperatures, using encapsulation techniques, or exploring alternative drying methods like freeze-drying for particularly heat-sensitive materials. Controlling parameters such as droplet size, air velocity, and moisture content can also play a crucial role in minimizing degradation and ensuring product quality.

- Addressing stickiness and fouling often involves optimizing the feed formulation, adjusting drying conditions, or incorporating appropriate additives to modify the product’s surface properties.

- Particle agglomeration can be mitigated through careful control of drying conditions, the use of appropriate additives, or the implementation of post-drying processing steps like milling or sieving.

- Improving energy efficiency can involve heat recovery systems, optimizing air flow patterns, and exploring alternative energy sources or drying techniques when feasible.

By addressing these challenges and considerations proactively, manufacturers can leverage the full potential of the spray drying method, ensuring consistent product quality, operational efficiency, and long-term sustainability.

Ready to optimize your instant coffee production with an industry-leading spray drying solution? Contact our experts today to discuss how our advanced systems can elevate your business.

Conclusion

Spray drying stands as a cornerstone in the production of instant coffee, offering a blend of efficiency, quality, and versatility. Its widespread adoption across various industries underscores its importance as a technological marvel, capable of transforming liquids into powders with precision and consistency. As consumers continue to demand convenient, high-quality products, spray drying remains at the forefront of meeting these needs, ensuring that your morning cup of instant coffee is just a few seconds away.