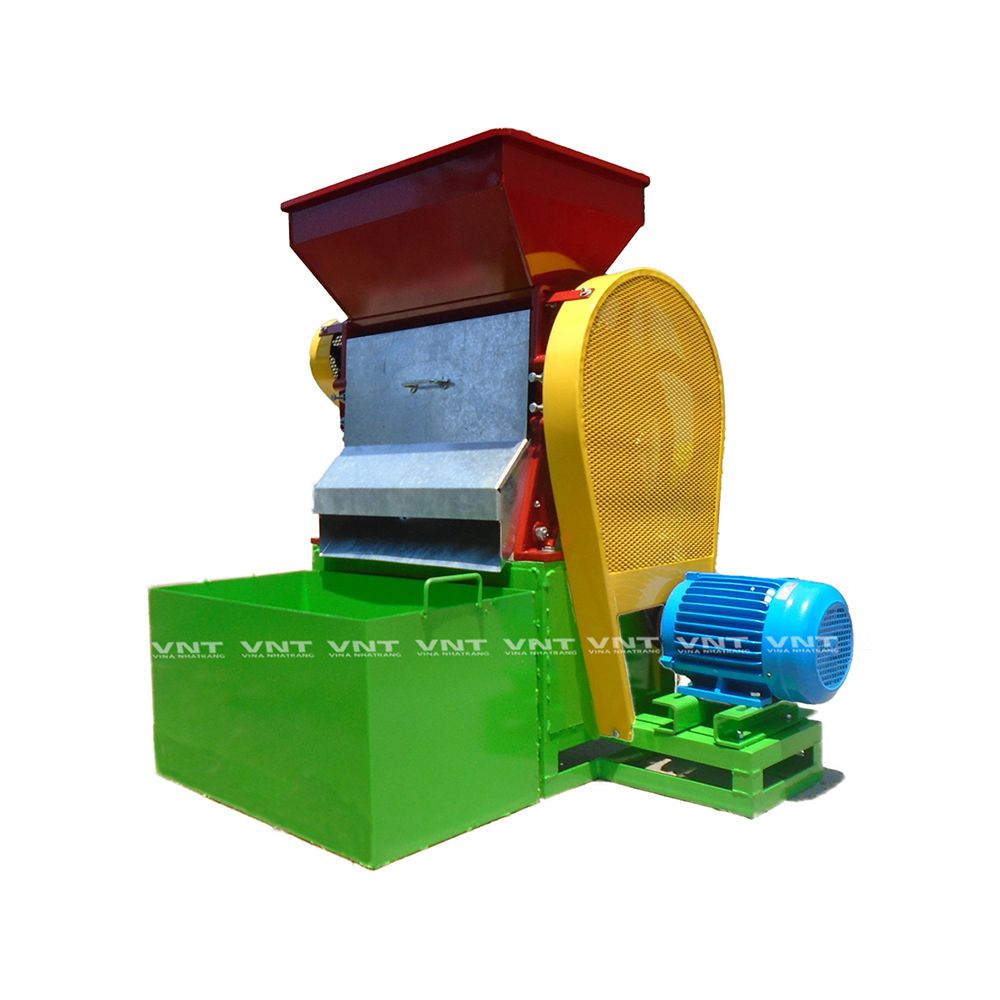

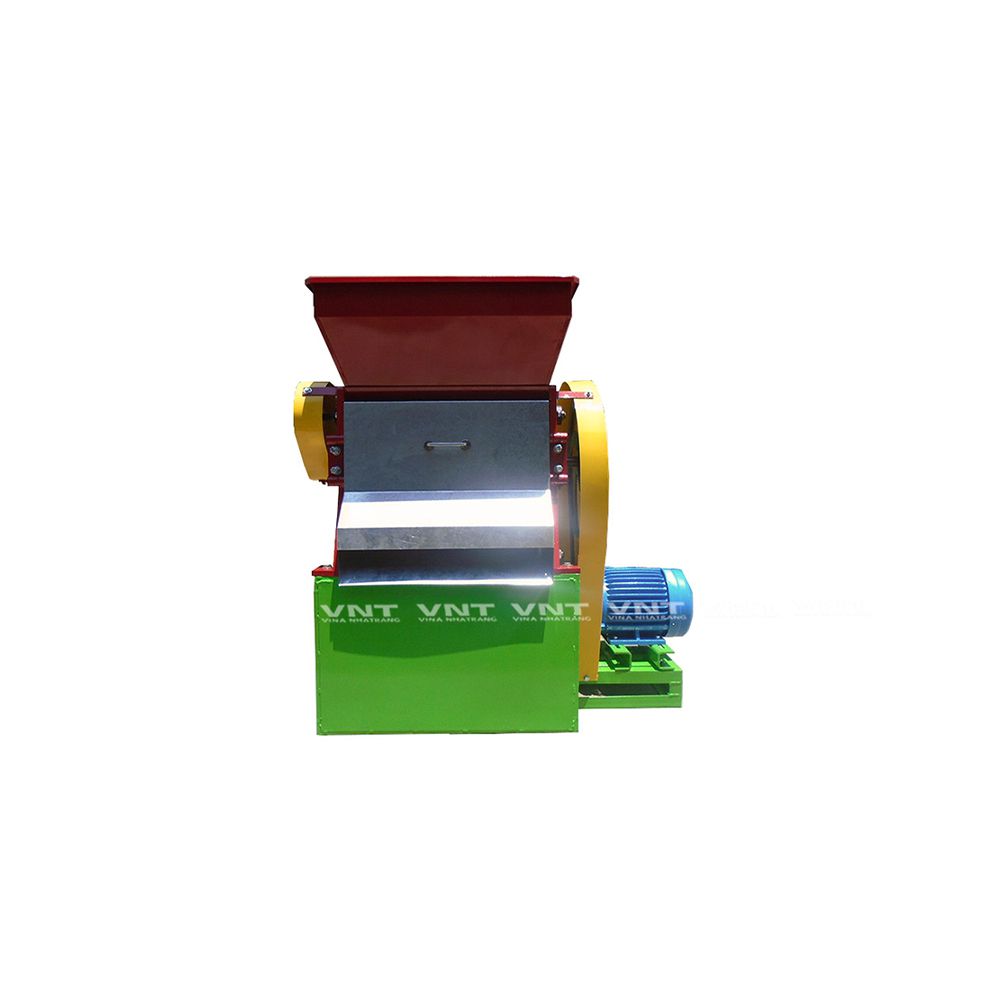

CHERRY PULPER MACHINE CPF1000

- Automates the pulping process.

- Increases efficiency and productivity compared to standard models.

- Delivers consistent pulping, minimizing variations that can affect coffee quality.

- Prepares the wet parchment coffee for the next stage of processing

- Saves time and labor compared to manual pulping methods.

What is the Cherry Pulper Machine CPF1000 ?

Processing Arabica and Robusta coffee cherries after harvesting involves removing the pulp to separate them into wet parchment coffee and pulps. This crucial step prepares the beans for further processing and drying.

The VNT's Cherry Pulper Machine CPF1000 excels in this task, offering several key benefits to coffee processors. By automating the pulping process, it streamlines the workflow, potentially leading to increased efficiency and enabling larger processing volumes. Moreover, the machine promotes consistent results, minimizing the variations inherent in manual pulping methods. This translates to higher-quality coffee and improved overall processing outcomes. Furthermore, the wet parchment coffee produced by the CPF1000 model is prepared for the next stage, which typically involves removing the mucilage layer through fermentation followed by drying.

Technical Specifications

Cherry Pulper Machine CPF1000's functions

- High performance of pulping

- The milling blade can be adjusted to suit with each type of coffee.

- Used conventional power supply: 220V – 1 Phase

Cherry Pulper Machine CPF1000's specifications

| Model | Capacity (kg/hour) | Power (HP) | Dimension (LxWxH, mm) |

| CPF1000 | Arabica: 1000 – 1200 Robusta: 500 – 600 | 2.0 | 1120 x 666 x 1263 |

Cherry Pulper Machine CPF1000's advantages

- High accuracy, high effective of seperation

- Modern technology

- High durability

- Easy to operate

- Electricity saving

Frequently Asked Questions

I want to know how to visit VNT's sample system?

VNT has more than 30 years experience in manufacturing equipment and systems for processing agricultural products such as coffee, pepper, cocoa … in Vietnam and over the world. Depending on your requirement of machine capacity and factory’s location, we will give the most suitable advice as well as arrange a suitable place for you to visit. Please contact to our hotline 0966 757 757 to get more information.

I want to know about VNT warranty policy?

VNT provides free warranty service within 12 months from the date of delivery of the product for mechanical parts.

I want to know how to contact to VNT?

Please contact to our hotline 0966 757 757 for supporting. In addition, you can leave a message in the “Contact for Price” section below, we will get back to you within 24 hours.