Introduction

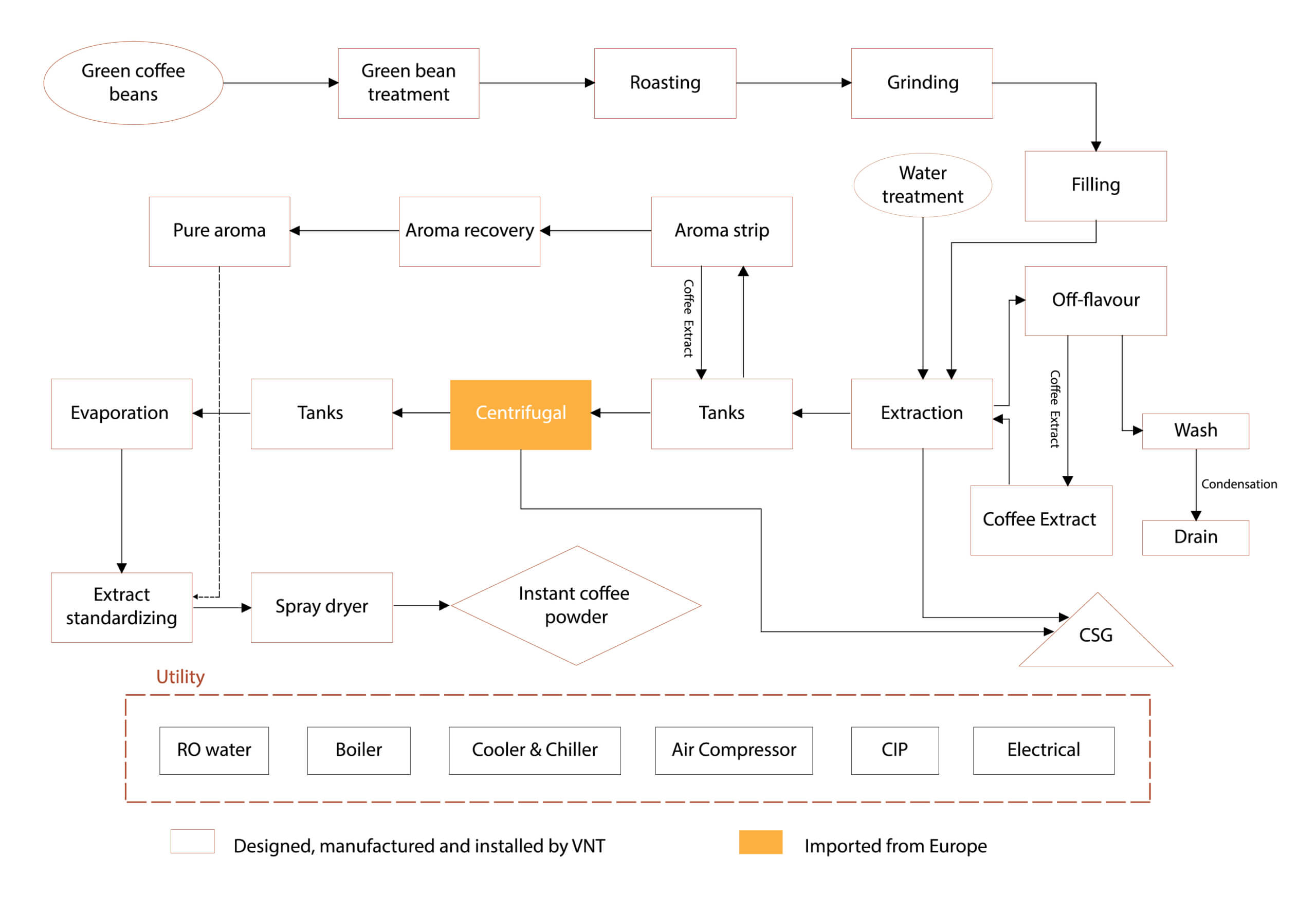

In the fast-paced world of coffee consumption, soluble coffee, commonly known as instant coffee, has carved out a significant niche. For coffee business owners looking to expand their product line or venture into the instant coffee market, understanding the manufacturing processes is crucial. This guide explores the intricate steps involved in producing soluble coffee, from bean selection to the final product, with insights into the key machinery that makes it all possible.

Choosing the Right Raw Materials

The foundation of any great coffee product lies in the quality of its raw materials. For soluble coffee, this process begins with:

- Selecting high-quality green coffee beans;

- Cleaning and dusting the beans to remove impurities;

- Roasting the beans according to international standards.

The roasting process is particularly crucial as it ensures uniformity in color and ripeness across all beans. Advanced roasting technology helps preserve the original flavor profile, setting the stage for a superior instant coffee product.

Roasting and Grinding

After roasting, the beans undergo a precise grinding process. This step is critical because:

- The particle size of the ground coffee directly affects the extraction process;

- Proper grinding ensures optimal flavor extraction in later stages;

- Consistency in grind size contributes to the overall quality and taste of the final product.

For coffee business owners, investing in high-quality grinding equipment can make a significant difference in the end product’s taste and consumer appeal.

Extraction

The heart of soluble coffee production lies in the extraction process. This stage utilizes an Instant Coffee Extraction System, typically featuring a tower extractor. Here’s how it works:

- Hot water (80-90°C) is introduced to the ground coffee;

- The water moves through the coffee grounds, extracting soluble substances;

- The process is repeated multiple times to maximize extraction;

- Dissolved coffee materials are collected at the top of the extractor

This method ensures efficient extraction of flavors and aromas, forming the base of your instant coffee product.

Concentration

Once extracted, the coffee solution undergoes concentration using an Instant Coffee Evaporation System. This process:

- Concentrates the coffee solution to 30-33% solids;

- Uses vacuum concentration to reduce pressure and preserve flavor;

- Prepares the extract for the drying phase.

Efficient concentration is key to producing a high-quality instant coffee, as it impacts both flavor intensity and production efficiency.

Drying

The drying phase is where your liquid coffee extract becomes the familiar granules or powder. Two primary methods are used:

- Freeze-drying

- Spray drying

While freeze-drying can produce a higher quality product, spray drying is faster and more cost-effective, making it a popular choice for many manufacturers. An Instant Coffee Spray Dryer atomizes the concentrated extract into hot air, resulting in a powder form. The choice between these methods can significantly impact your product’s texture, solubility, and overall quality.

## Aroma Recovery

One of the biggest challenges in instant coffee production is preserving the rich aroma of freshly brewed coffee. An Instant Coffee Aroma Recovery System addresses this issue by:

1. Capturing the volatile aroma compounds before extraction

2. Preserving these compounds throughout the manufacturing process

3. Reintroducing the aroma to the dried coffee

This process, involving desorption and adsorption techniques, ensures that your final product retains a rich flavor profile that closely mimics freshly brewed coffee.

## Packaging and Storage

The final steps in the soluble coffee manufacturing process are packaging and storage. To maintain quality:

– Package the product immediately after production

– Use airtight containers to prevent moisture absorption

– Store in controlled conditions with proper lighting, temperature, ventilation, and humidity

These steps are crucial in preserving the quality of your instant coffee until it reaches the consumer.

## Conclusion

Soluble coffee manufacturing is a complex process that balances efficiency with flavor preservation. For coffee business owners, understanding these processes and the machinery involved—from extraction systems to aroma recovery technology—is key to producing a high-quality instant coffee product.

While soluble coffee undergoes significant processing, technological advancements continue to improve taste and aroma retention. By leveraging these innovations, you can offer consumers a convenient alternative to traditional brewing methods without compromising on flavor.

As the demand for convenient coffee solutions grows, mastering the art and science of soluble coffee manufacturing can open new avenues for your coffee business, allowing you to tap into a market that values both quality and convenience.

Would you like me to elaborate on any specific part of the manufacturing process or discuss how these processes might apply to different scales of production?