SUMMARY OF PROCESSING FACTORS AFFECTING COFFEE QUALITY

The following table present a summary of processing factors and their potential problems, which can influence Arabica quality in the washed / semi-washed processes.

| Process step | Factors reducing quality | Potential problem |

| Harvesting cherry | Harvest green cherry | Green or grassy flavour |

| Harvest over-ripe cherry | Fermented or fruity flavour | |

| Pick fallen old cherry from the ground | Fermented or fruity flavours. Mould contamination producing mouldy or musty flavours | |

| Hold fresh cherry for long periods before pulping | Fermented or fruity flavours | |

| Pulping cherry | Poor quality pulping equipment or poorly adjusted equipment | Nipped beans causing stinker beans |

| Fermentation | Over-fermentation | Fermented, fruity, sour or onion flavour |

| Poor hygiene in fermentation tanks leaving a small number of extremely over fermented beans | Stinker beans producing foul rotted or sour flavours | |

| Washing | Poor washing leaving mucilage on parchment | Mould growth producing mouldy or musty flavours |

| Hulling dry parchment | Incorrect huller setting | Bean damage |

| Coffee too dry | Bean damage | |

| Storing hulled green bean | Storing too wet | Mould growth producing and mouldy or musty flavours |

| Stored near fuels or chemicals | Contaminate with foul odours | |

| Stored in jute bags made on machinery lubricated by petroleum oils | Contaminated with baggy or oily taints | |

| Stored in hot humid condition for long periods | Mould growth producing mouldy or musty flavours. Surface oxidation of beans causing woody flavoursFaded bean colour | |

| Transport | Rewetting of coffee due to leaky tarpaulins or containers | Mould growth producing mouldy or musty flavours |

Source: Arabica coffee manual – Edward Winston, Jacques Op de Laak, Tony Marsh, Herbert Lempke and Keith Chapman

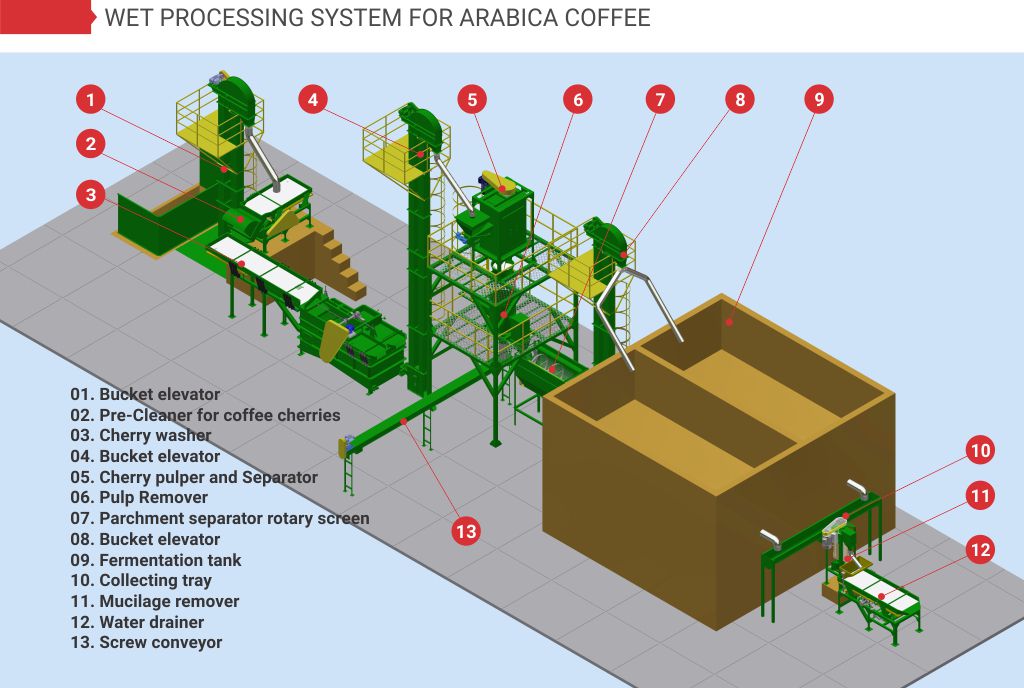

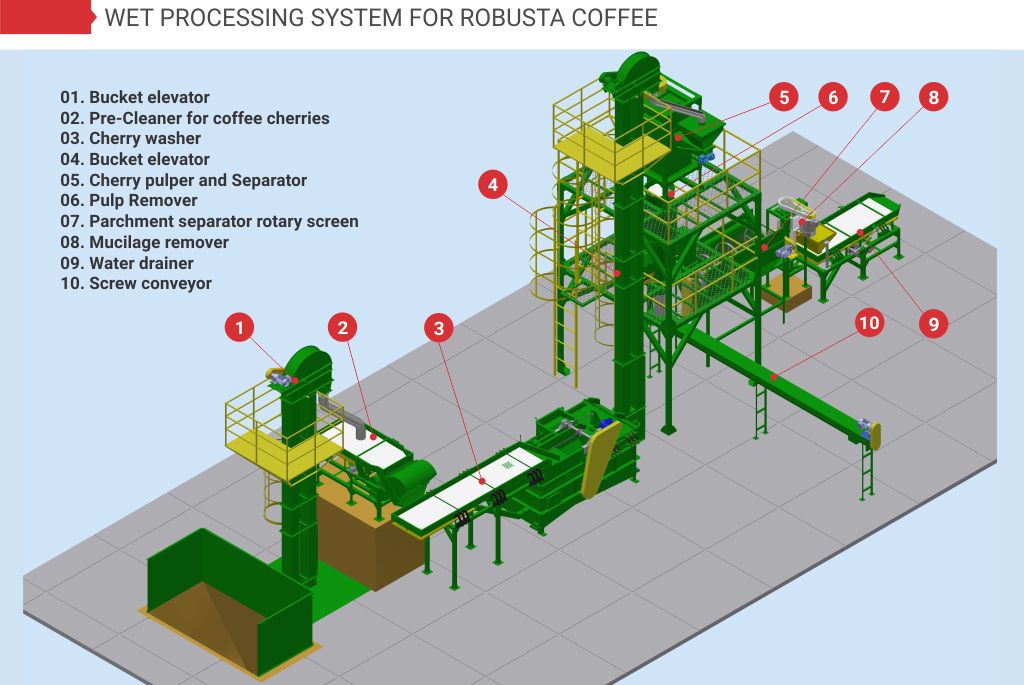

VINA NHA TRANG MECHANICAL JOINT STOCK COMPANY provides a full range of machines and equipment for the production line of Robusta & Arabica coffee beans. For more details of each product line, please visit the link below:

- WET COFFEE PROCESSING SYSTEM

- GREEN COFFEE PROCESSING SYSTEM

- ROASTING & GRINDING COFFEE SYSTEM

- ROASTER COFFEE MACHINE

- DRYING COFFEE SYSTEM

OUR COMPANY PROVIDES CONSULTANT, DESIGN FOR THE ENTIRE COFFEE PROCESSING SYSTEM ACCORDING TO SPECIFIC DEMAND FROM CUSTOMERS. PLEASE CONTACT TO OUR HOTLINE 0966 757 757 OR OUR EMAIL SALES@VINANHATRANG.VN FOR MORE DETAILS.