The distinct aroma and flavor of freshly roasted coffee beans are the hallmarks of a quality coffee product. For commercial coffee roasters, achieving consistent results at a large scale requires investing in industrial-grade coffee roasting machines. However, these powerful machines come with a hefty price tag.

This comprehensive guide delves into the true cost of industrial coffee roasters, exploring the factors that influence pricing and providing insights to help businesses make informed investment decisions.

What is an Industrial Coffee Roaster?

Understanding Industrial Coffee Roasters Industrial coffee roasters are designed to handle high-volume roasting operations, with batch sizes typically ranging from 60kg to well over 250kg. These large-capacity machines are essential for commercial coffee companies seeking to meet the ever-increasing demand for their products.

Explore VNT’s Industrial Coffee Roasters with batch size ranging from 60kg to well over 250kg

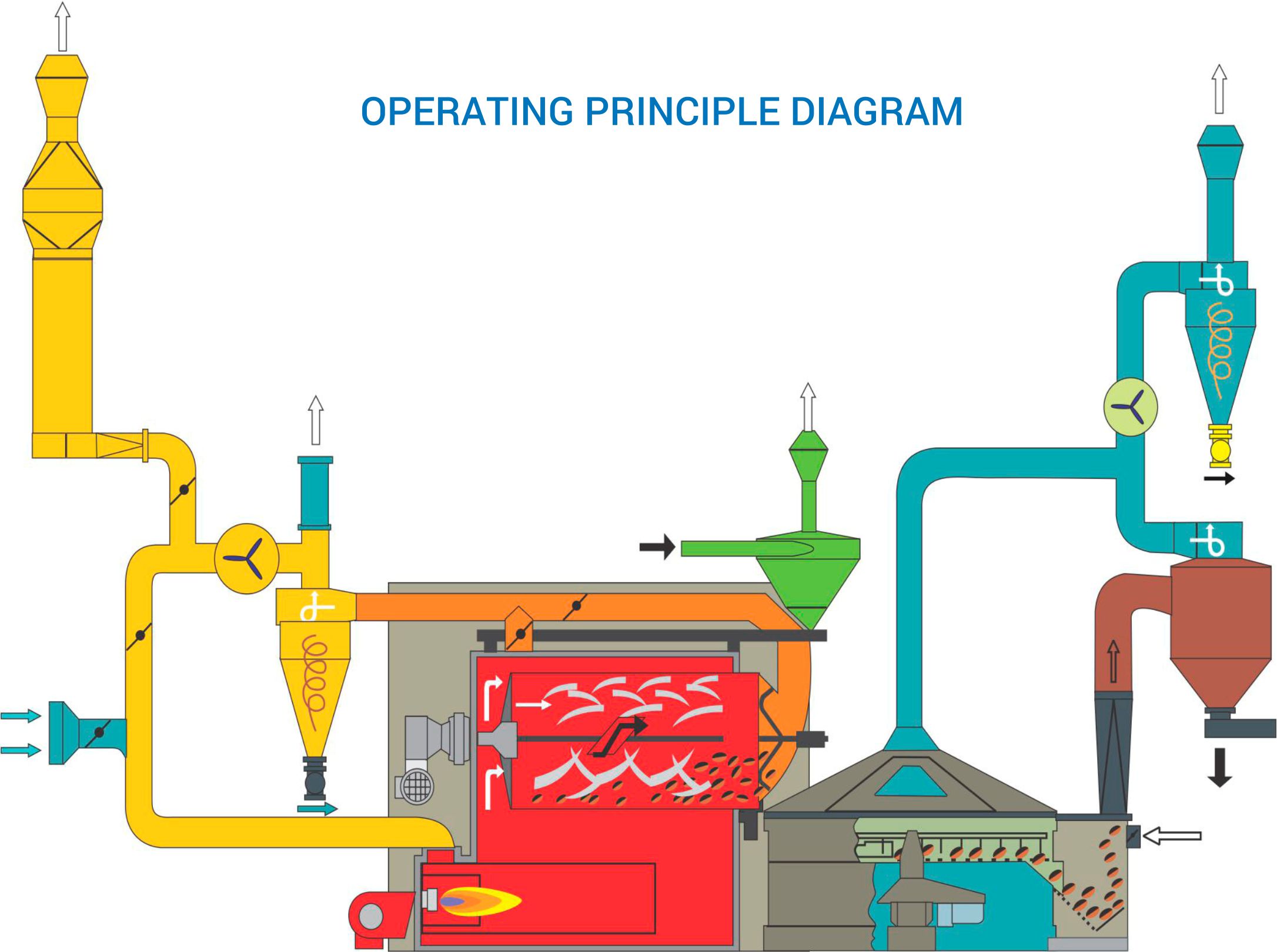

The two primary types of industrial coffee roaster are drum roasters and fluid bed roasters. Drum roasters tumble the beans inside a rotating drum, and fluid bed roasters use hot air to roast the beans in a fluid-like motion.

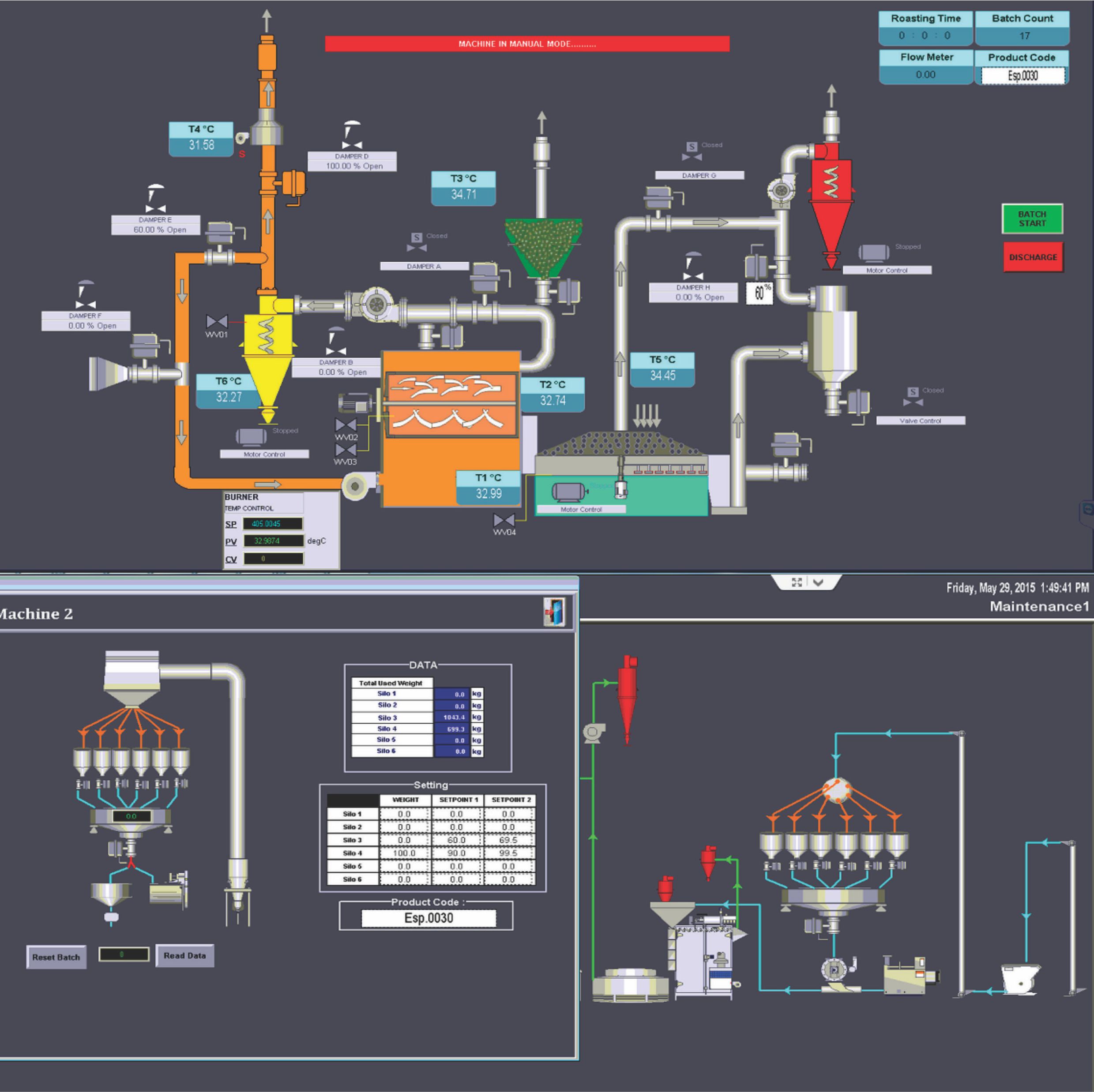

Advanced computer controls allow roasters to precisely monitor and adjust variables like time, temperature, and airflow to achieve the desired roast profile consistently across large batches.

Explore the technologies Vina Nha Trang Engineering JSC applied in our Industrial Coffee Roasting System

What are the factors affecting the cost of an industrial coffee roaster?

1. Roaster Type and Capacity:

The type of industrial roaster greatly impacts the cost. Fluid bed roasters, which use hot air to roast the beans in a fluid-like motion, are generally more expensive than traditional drum roasters that tumble the beans in a rotating drum. This is because fluid bed roasters have more complex designs and require specialized components like air injection systems.

Larger batch sizes also drive up costs exponentially due to the increased size and material requirements. The larger the batch capacity, the more robust and heavy-duty the machine needs to be.

2. Features and Automation:

The level of technology and automation included with an industrial roaster can greatly increase its cost. Basic models with manual controls tend to be cheaper, while advanced features like touchscreen interfaces, internet connectivity, afterburners for smoke reduction, and automated roast profile tracking/adjustment systems drive up the price substantially due to their added complexity. Some high-end models even incorporate artificial intelligence to optimize roast cycles.

3. New vs. Used:

Purchasing a used or refurbished industrial coffee roaster presents an opportunity for significant cost savings—often 30-50% less than buying new equipment. However, the remaining lifespan, service history, and maintenance requirements must be carefully evaluated. It’s generally advisable to only purchase used roasters from reputable sources that can verify their condition.

4. Installation and Setup:

Beyond the roaster itself, the installation, setup and commissioning by the manufacturer’s technicians represent additional costs that must be budgeted for. This may involve making facility modifications like installing sufficient ventilation, gas/electrical lines, and securing appropriate permits. For large industrial roasters, these associated costs can sometimes exceed thoudsands of dollars or more.

Howerver, the cost of installation and setup varies on the existing system and machines you’re using as well as the available space in your system, with a well organized system of machinary you can greatly reduce the cost of industrial coffee roaster installation and setup.

Get consultation from our technicians on the cost of installing an VNT’s Industrial Coffee Roasting System

Conclusion

Investing in an industrial coffee roaster is a major financial commitment, with costs ranging from thoudsands of dollars for smaller models to over hundreds of thousands of dollars for large-scale, feature-rich machines. However, this upfront expenditure is critical for commercial roasters seeking to meet production demands while maintaining consistency and quality.

By carefully evaluating your roasting needs, exploring cost-saving strategies, and accounting for ongoing operational expenses, you can make an informed decision that positions your coffee roasting business for long-term success in a competitive industry.