CHERRY SIZE GRADER

- Increased efficiency: Automates the sorting process, significantly reducing labor costs and time compared to manual sorting.

- Consistency: Ensures uniform sizing of cherries, meeting market standards and consumer expectations.

- Improved quality control: Helps identify and separate defective or substandard fruits, maintaining overall product quality.

What is the cherry size grader ?

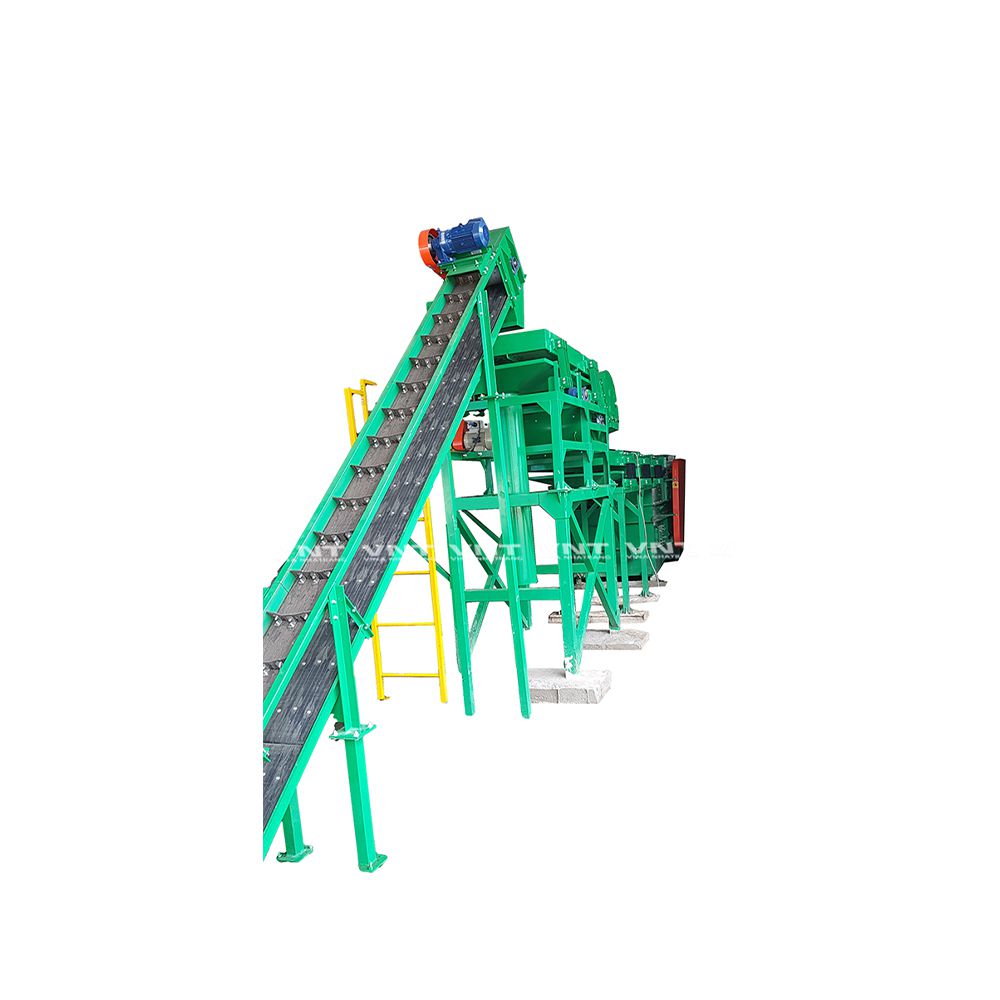

A cherry size grader is a specialized piece of agricultural equipment designed to sort cherries based on their size. This machine plays a crucial role in the post-harvest processing of cherries, helping growers and packers to efficiently categorize their fruit for different markets and uses.

The primary function of a cherry size grader is to separate cherries into uniform size categories. This is important because cherries of similar sizes are typically sold together, as consumers and buyers often prefer consistency in their fruit. Additionally, different sizes may be destined for different purposes - larger cherries might be sold fresh in premium markets, while smaller ones could be used for processing into jams, juices, or other products.

Technical Specifications

Product's structure

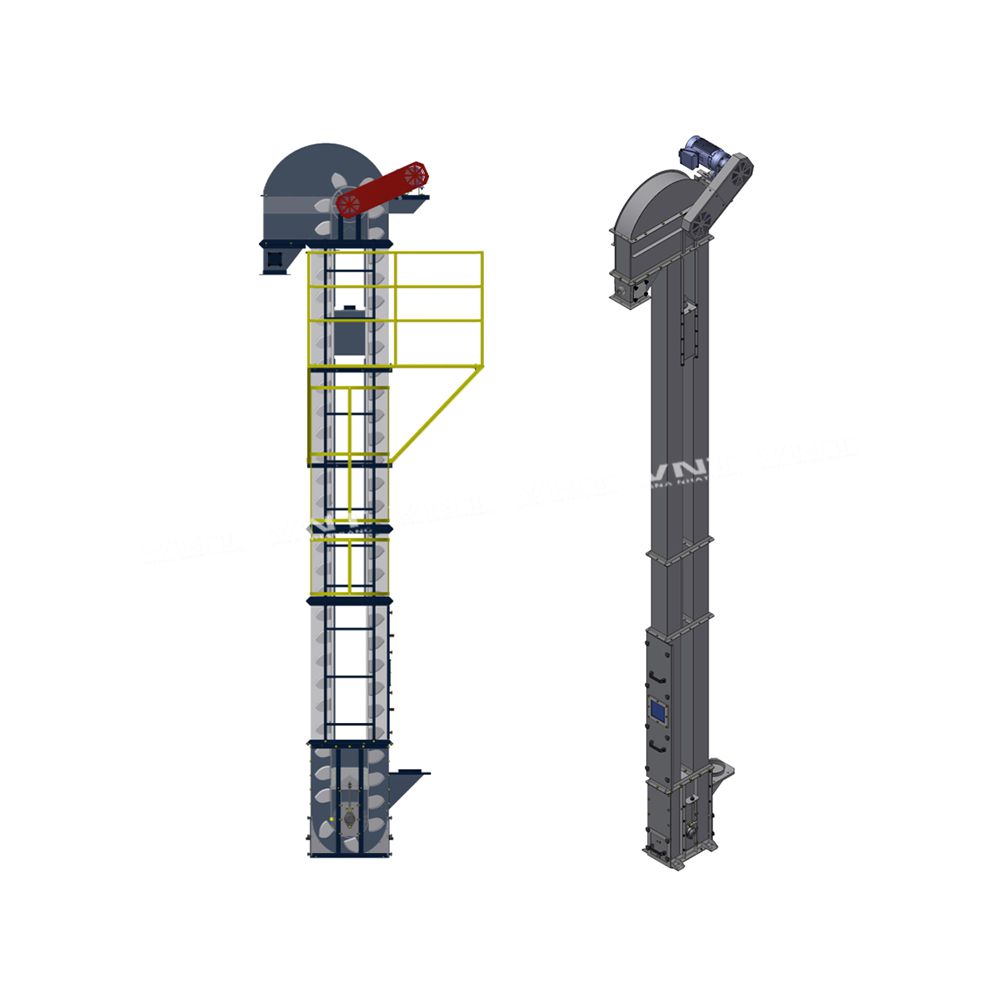

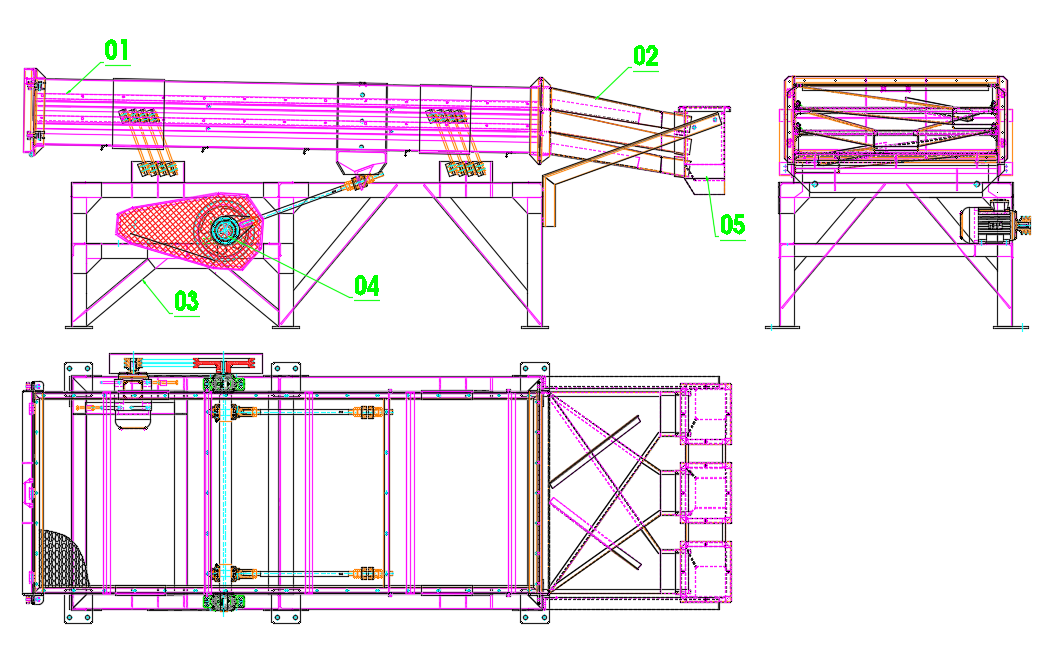

CHERRY SIZE GRADER STRUCTURE

- Three-tier vibrating sieve for sorting. 2. Output chute assembly.

- Leg frame. 4. Drive assembly.

- Collection hopper assembly.

Product's technical specifications:

| Model | Capacity (ton/h) | Power drive (HP) | Dimensions (D x R x C mm) |

|---|---|---|---|

| KTQ | 1 – 3 | 2 | 3300 x 1300 x 1280 |

Product's operating principle

- Materials move from the beginning to the end of the chute: the chute is designed with a slope.

- When coffee cherries are fed onto the vibrating screen, fruits smaller than the first tier mesh will fall to the second tier, fruits smaller than the second tier mesh will fall to the third tier. Then they all move towards the output chute assembly in three different directions, pouring into the collection hopper assembly to be moved to each desired position.

Frequently Asked Questions

How to care and maintain VNT's cherry size grader?

Care and maintenance of the sorting machine must be carried out correctly and on time to extend the machine’s stability and lifespan: Daily care: After each work shift, clean the machine by: Removing fruits stuck in the mesh holes and any remaining on the sieve Using a water hose to wash away soil adhering to the floor, troughs, etc. Weekly care In addition to daily care, perform the following: Grease the bearings of the fruit sorting machine. Check the tension of the belts, adjust if necessary. End-of-season care All bearings must be completely disassembled, cleaned of old grease, inspected, and if the bearing rings are excessively worn, they must be replaced. Apply new grease for preservation until the next season. Check the belts, replace if excessively worn Clean the entire equipment and repaint components for preservation.

Tips when installing VNT's cherry size grader?

When installing, pay attention to the following points: The machine must be placed on a flat, firm, and dry foundation. Always maintain necessary clearances around the machine to facilitate easy inspection, repair, and maintenance.