COCOA DRYING SYSTEM

- The system boasts a drum dryer capacity of 15 m³, enabling efficient drying of large volumes in a single batch.

- Focuses on durability and corrosion resistance in a food processing environment, contributing to a longer lifespan for the equipment.

- Enhances the system’s mobility for flexible placement within the workspace.

- Offers flexibility in terms of operational costs by allowing you to choose the most cost-effective or available fuel option.

What is the cocoa drying system ?

The VNT's Cocoa Drying System plays a crucial role in post-fermentation cocoa processing. During fermentation, the foundation for cocoa's unique flavor profile is established. The drying process acts as a critical subsequent step, influencing the final characteristics of the cocoa beans. VNT's system is designed to address this need with several key benefits:

- Capable of handling large batches of cocoa beans: The system boasts a drum dryer capacity of 15 m³, enabling efficient drying of large volumes in a single batch. This translates to improved drying efficiency, particularly for high-volume cocoa producers.

- Stainless steel for the feeding hopper: Focuses on durability and corrosion resistance in a food processing environment, contributing to a longer lifespan for the equipment. This emphasis on quality construction is vital for ensuring consistent performance and hygiene during the drying process.

Technical Specifications

Product's functions & operation

- Used to dry Cocoa

- Drum dryer capacity V = 15 m3/batch

- Feeding hopper: made by stainless steel

- Equip wheels for moving frame

- Fuel: wood, husk, coal

- Indirect heating

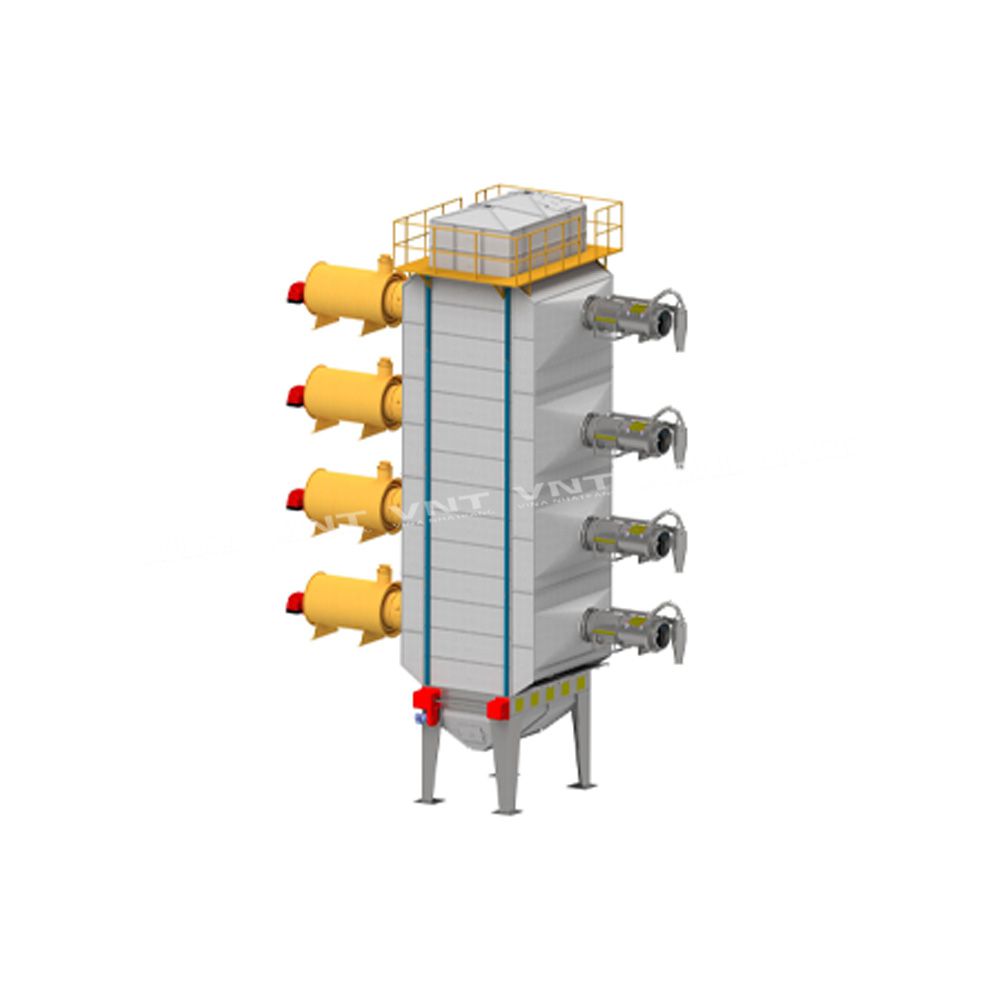

Product's picture of system

Product's advantages

- Modern technology

- High durability

- Easy to operate

- Improve processing efficiency for the whole system

- Minimize labor workforce in the processing line

Frequently Asked Questions

I want to visit VNT's sample system?

VNT has more than 30 years experience in manufacturing equipment and systems for processing agricultural products such as coffee, pepper, cocoa … in Vietnam and over the world. Depending on your requirement of machine capacity and factory’s location, we will give the most suitable advice as well as arrange a suitable place for you to visit. Please contact to our hotline 0966 757 757 to get more information.

I want to know about VNT warranty policy?

VNT provides free warranty service within 12 months from the date of delivery of the product for mechanical parts.

I want to know how to contact to VNT?

Please contact to our hotline 0966 757 757 for supporting. In addition, you can leave a message in the “Contact for price” section below, we will get back to you within 24 hours.