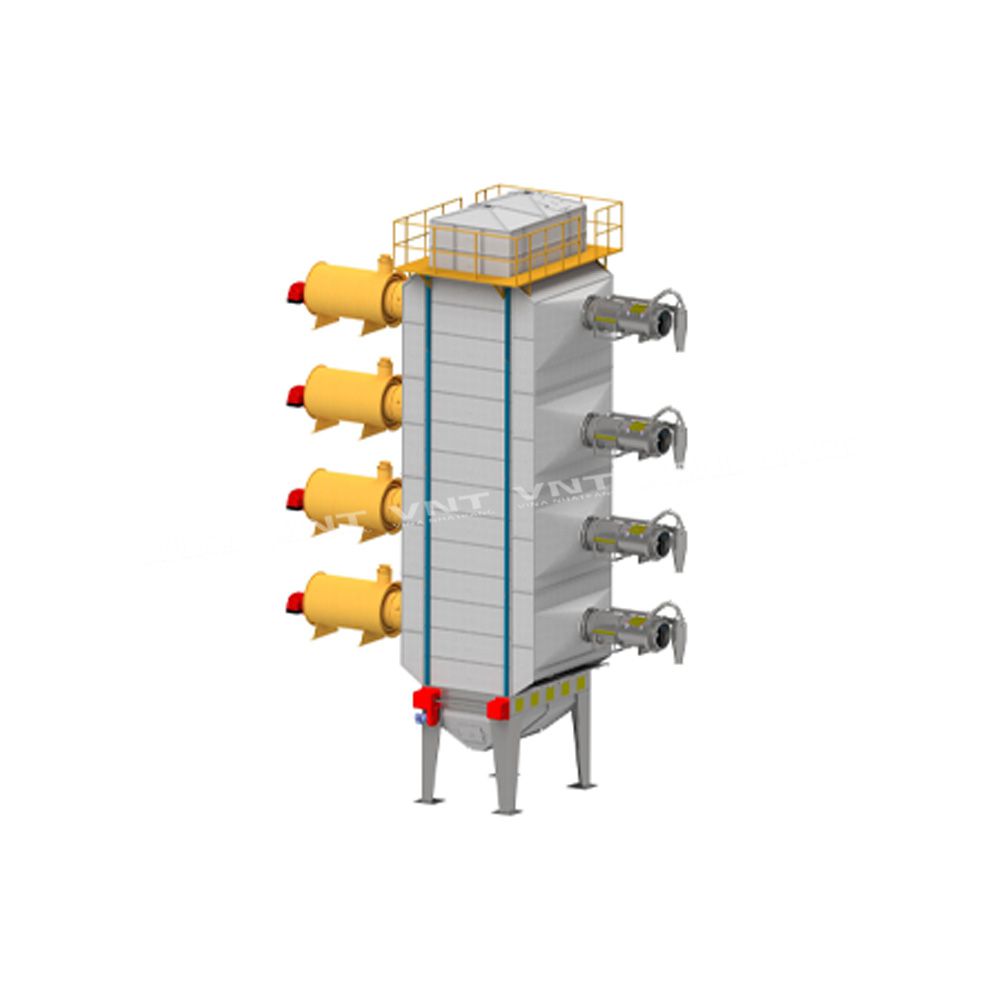

VIBRATING DRYER

- Offers the flexibility to handle coffee bean drying in either continuous or batch mode

- The indirect heating method help minimize potential damage to the coffee beans during drying

- Offers a variety of fuel options, including rice husk, firewood, coal, pellet, and DO oil

What is the vibrating dryer ?

The VNT's Vibrating Dryer plays a vital role within the coffee processing system, ensuring the efficient drying of coffee beans while safeguarding their inherent qualities. This versatile system offers continuous or batch drying operations, providing flexibility to adapt to the specific needs of your production line and coffee bean volumes. The Vibrating Dryer stands out for its key benefits:

- Quality-Preserving Drying and Operational Efficiency: The dryer prioritizes the preservation of coffee bean quality throughout the drying process. It utilizes an indirect heating method, where heat from the burner is delivered via a blower. This gentle approach minimizes the risk of damaging the coffee beans during drying, helping to retain their natural flavors and characteristics. Furthermore, the Vibrating Dryer offers a variety of fuel options, including rice husk, firewood, coal, pellet, and DO oil. This flexibility can significantly impact operational costs by allowing you to select the most cost-effective or readily available fuel source for your location.

Technical Specifications

Product's functions

- Used to continuously dry coffee beans in the coffee processing system

- Drying the coffee bean after getting wet will preserve their best natural quality.

- Heat is derived from the burner indirectly via blower

- Can be dried continuously or in batches depending on the input materials

- Fuel material: rice husk, firewood, coal, pellet, DO oil…

Product's specifications

| Capacity (ton/hour) | Installed Power (HP) | Dimension (L x W x H,mm) |

| 5 ÷ 7 | 30 HP – 3 phase | 9400 x 1860 x 2100 |

Product's picture of system

Product's advantages

- Fast moisture reduction

- Control temperature during drying process

- High durability

- Easy to operate

- Energy saving

Frequently Asked Questions

I want to know how to visit VNT's sample system?

VNT has more than 30 years experience in manufacturing equipment and systems for processing agricultural products such as coffee, pepper, cocoa … in Vietnam and over the world. Depending on your requirement of machine capacity and factory’s location, we will give the most suitable advice as well as arrange a suitable place for you to visit. Please contact to our hotline 0966 757 757 to get more information.

I want to know about VNT warranty policy?

VNT provides free warranty service within 12 months from the date of delivery of the product for mechanical parts.

I want to know how to contact to VNT?

Please contact to our hotline 0966 757 757 for supporting. In addition, you can leave a message in the “Contact for Price” section below, we will get back to you within 24 hours.