Coffee is among the world’s most popular beverages, enjoyed by millions each day. The journey from raw coffee cherries to the green coffee beans ready for roasting is crucial in shaping a coffee’s quality and flavor profile. Green coffee processing refers to the methods used to remove the outer layers of the cherries, preparing the beans for the next stage: roasting. In this guide, we’ll break down the different green coffee processing techniques, highlight their benefits, and examine the systems that make it all possible.

What is a Processing Method?

A processing method refers to all the steps involved in removing the fruit from around the coffee bean and drying it. These methods can vary significantly based on the country and region where the coffee is produced. Traditionally, the chosen method depends on factors such as the availability of water, the amount of space the producer has, and the local weather and climate conditions.

What Are Common Green Coffee Processing Methods?

Wet Processing (Washed)

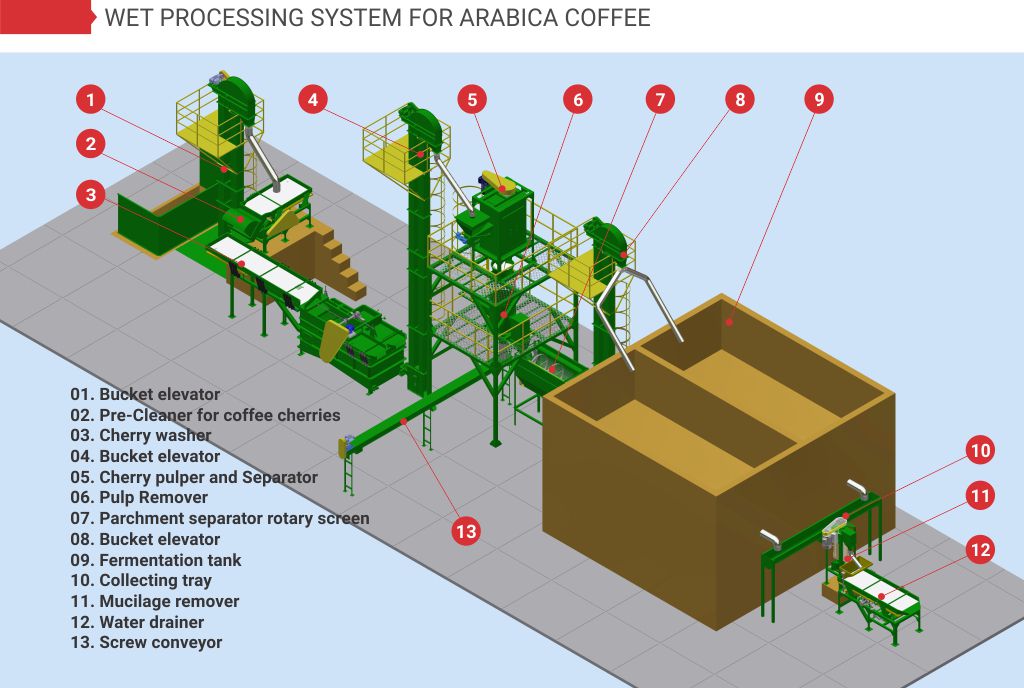

The wet processing method, also called the washed method, is a popular technique used to produce high-quality green coffee beans. The process involves several key steps:

- Washing: Coffee cherries pass through a vibrating sieve to remove debris like branches, leaves, and stones. They are then transferred to a water-based washing machine, where they undergo further cleaning and quality classification before pulping.

- Pulping: The cleaned coffee cherries are mechanically pulped to strip away the outer skin and pulp. This leaves the beans covered in a sticky, parchment-like layer. The VNT‘s Coffee Pulping Machine efficiently removes the fruit flesh, significantly speeding up the process and reducing labor compared to manual methods.

- Fermentation: The pulped beans are then fermented to break down the remaining mucilage (the sticky substance clinging to the beans). Fermentation is a crucial step, impacting the coffee’s flavor profile.

See how Fermentation plays out in VNT‘s Wet Coffee Processing System

- Mucilage Removal: After fermentation, the beans are washed thoroughly to remove any residual mucilage. VNT‘s Mucilage Coffee Remover Machine ensures a consistent quality finish, reduces the risk of broken beans, and preserves the beans’ natural color.

- Drying: The washed beans are dried either by spreading them on raised beds or using mechanical dryers until they reach the optimal moisture content. Effective drying systems are essential to maintain bean quality and prevent defects.

Some of the most effective Drying Systems for this method

Dry Processing (Natural or Unwashed)

The dry processing method, also known as the natural or unwashed method, is commonly used in areas with limited water availability or for specific coffee varieties. This method includes the following steps:

- Drying: Whole coffee cherries are spread out to dry in the sun or in mechanical dryers. They are dried until the outer layers become brittle, which can take several weeks if done outdoors. Proper drying is crucial to prevent mold and ensure even moisture distribution.

Explore some of the best Drying Systems for efficient dry processing.

- Hulling: Once the cherries are fully dried, they are mechanically hulled to remove the outer husk and reveal the green coffee beans. VNT‘s Huller & Polisher machine performs this step efficiently, minimizing bean damage and reducing overall processing time.

Semi-washed (Honey)

The semi-washed, or honey processing method, blends techniques from both wet and dry processing. Here’s how it works:

- Pulping: As in wet processing, the coffee cherries are pulped to remove the outer skin. However, a significant amount of the sticky mucilage remains on the beans.

- Drying: The pulped beans, still coated with mucilage, are spread out to dry, similar to the dry processing method. This step influences the coffee’s final flavor, often adding sweetness and complexity.

- Hulling: Once dried, the remaining layers are mechanically hulled to reveal the green coffee beans, ready for roasting.

Benefits of Each Processing Method

Benefit Of Wet Processing Method

- Produces a clean and consistent flavor profile

- Eliminates the fruity and fermented notes often found in dry-processed coffee

- Provides better control over fermentation and drying, enhancing quality and consistency

Benefit Of Dry Processing Method

- Uses minimal water and equipment, making it eco-friendly and cost-effective

- Preserves the coffee’s natural flavors and rich aromas

- Well-suited for regions where water resources are limited

Benefit Of Semi-washed (Honey) Processing Method

- Balances the distinct flavors of wet and dry processing

- Retains some natural fruity and floral notes, enhancing sweetness

- Creates a unique flavor profile that stands out from both washed and natural coffees

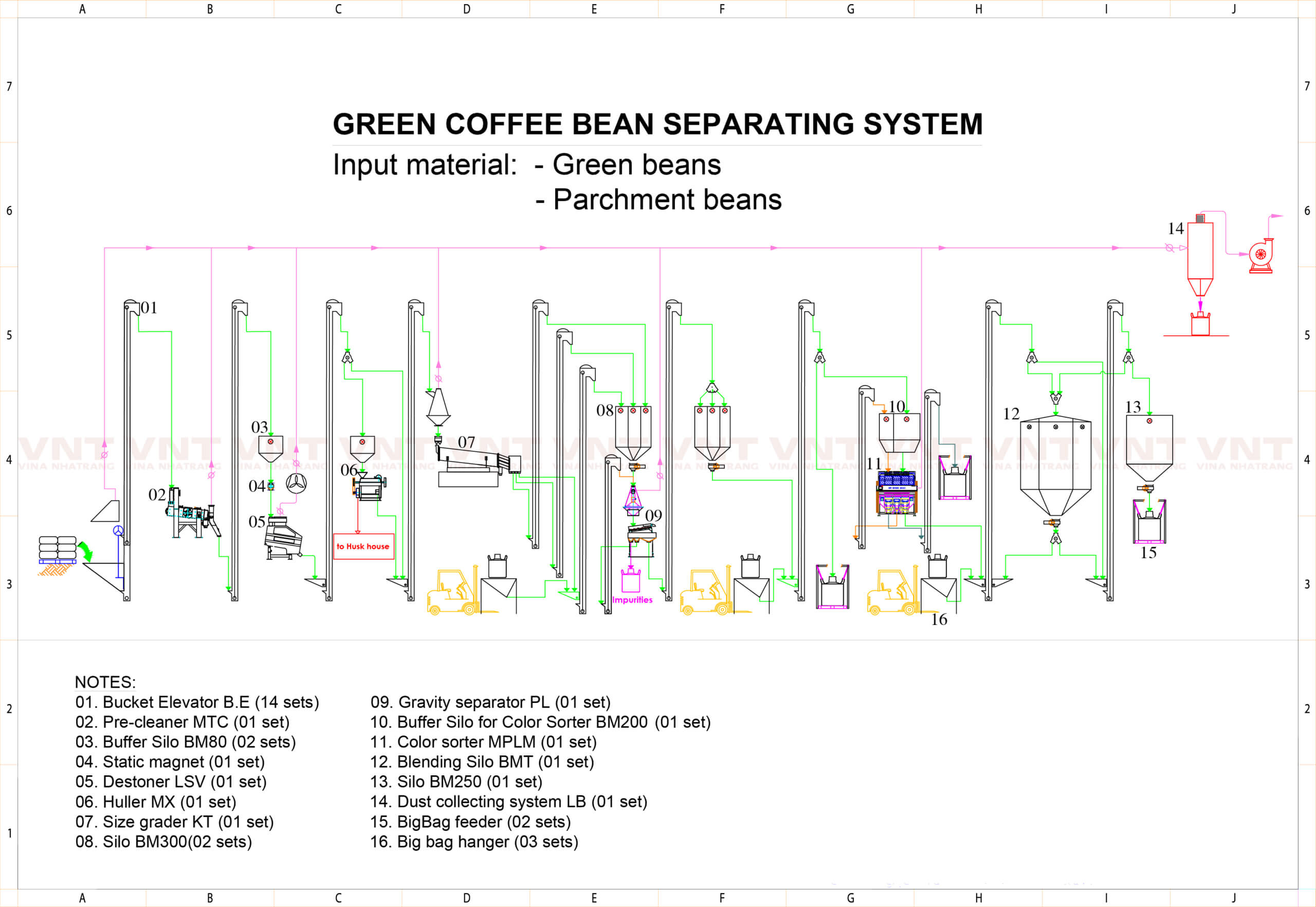

Green Coffee Processing Systems

Green coffee processing systems are engineered to efficiently manage each stage of transforming fresh coffee cherries into exportable green coffee beans. Depending on whether the wet or dry processing method is used, these systems consist of various specialized components.

Wet Processing Systems

- Pulping Machines: Mechanical devices that strip the outer skin and pulp from the coffee cherries, leaving the beans coated in mucilage.

- Fermentation Tanks: Controlled environments where the pulped beans ferment to break down the mucilage, crucial for developing flavor.

- Washing Channels: Channels or tanks designed to thoroughly wash the beans, removing any remaining mucilage after fermentation.

- Drying Systems: Options include raised beds, mechanical driers, or solar driers to dry the beans to the optimal moisture content.

Explore all machines used in the Wet Coffee Processing System

Dry Processing Systems

- Drying Systems: Entire cherries are spread on raised beds, or dried using mechanical or solar driers until the outer layers become brittle.

- Hulling Machines: Mechanical devices that remove the parchment, husk, or hull from the dried cherries, exposing the green coffee beans.

- Sorting and Grading Equipment: Systems that classify and grade beans by size, density, and quality to ensure uniformity.

Explore all machines used in the Dry Coffee Processing System

Both wet and dry processing systems may include additional equipment such as conveyors, elevators, and storage units to optimize the entire process.

Modern green coffee processing systems often feature advanced technologies like automated controls, moisture sensors, and energy-efficient drying mechanisms. These innovations enhance efficiency, improve consistency, and promote sustainability.

Conclusion

Green coffee processing is a critical step in the coffee production chain, directly influencing the final quality, flavor, and aroma of the coffee we savor. Understanding the different processing methods, their benefits, and the systems involved enables coffee producers to make informed choices tailored to specific quality goals and market preferences. Whether aiming for the clean, consistent flavors of wet-processed coffee, the vibrant, fruity notes of dry-processed beans, or the balanced profile of semi-washed coffee, green coffee processing techniques are essential in crafting the diverse and delightful coffee varieties we enjoy.