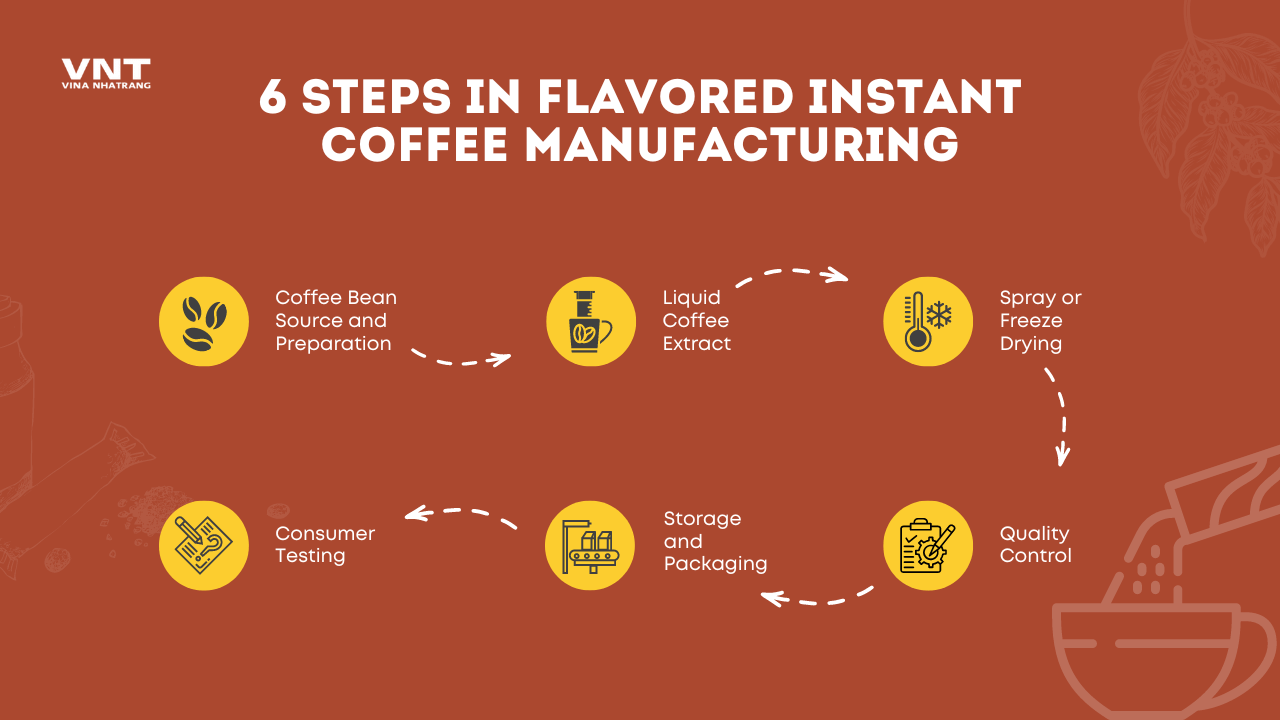

Have you ever wondered about the journey your favorite cup of hazelnut or vanilla-infused instant coffee takes before it reaches your mug? Today, we’re removing the curtain on the fascinating flavored instant coffee manufacturing process. From selecting the perfect beans to the final packaging, we’ll explore the intricate steps that transform raw coffee into the delightful, aromatic powder that dissolves effortlessly in your cup. Whether you’re a coffee aficionado or simply curious about the behind-the-scenes magic, this deep dive into the world of flavored instant coffee production promises to be an eye-opening experience.

Explore more: Key Steps & Technologies in the Instant Coffee Manufacturing Process

Coffee Bean Selection and Preparation – The Foundation

The careful selection and preparation of coffee beans are at the heart of every great cup of flavored instant coffee. This crucial first step sets the stage for the entire manufacturing process.

1. Harvesting – The Quest for Quality Beans

The journey begins with a meticulous selection of high-quality coffee beans. Manufacturers primarily focus on two varieties: Arabica and Robusta. Each brings its unique characteristics to the table:

- Arabica: Known for its smooth, complex flavor profile and lower caffeine content, Arabica beans are often the stars of the show. They offer a wider range of flavors, making them ideal for creating nuanced and sophisticated instant coffee blends.

- Robusta: With its stronger, more bitter taste and higher caffeine levels, Robusta beans contribute body and depth to the final product. They’re often used in combination with Arabica to create a well-rounded flavor profile.

High-quality coffee beans are selected to develop the desired flavor, intensity, and aroma

But where do these beans come from? Picture lush, misty mountainsides in Latin America, sun-drenched plantations in Africa, and the verdant hills of Southeast Asia. These diverse regions, each with its unique terroir, produce beans with distinct flavor notes that skilled coffee manufacturers blend to create their signature tastes.

Quality control begins right at the source. Factors like altitude, soil type, and climate play a significant role in shaping the beans’ flavor profile. Imagine a coffee cherry ripening slowly on a high-altitude Colombian mountainside, soaking up the perfect balance of sun and rain. This meticulous attention to sourcing ensures that only the best beans make it into your morning cup.

2. Roasting – Where Science Meets Art

Once the beans are selected, it’s time for them to face the heat – literally. Roasting is where the magic begins to happen, transforming the raw, green coffee beans into the aromatic brown beans we’re familiar with.

Picture a massive industrial roaster, filled with beans tumbling and turning as they’re exposed to carefully controlled high temperatures. The air fills with the intoxicating aroma of coffee as the beans undergo a remarkable transformation:

- Time is of the essence: Typically, roasting takes between 18-25 minutes per batch. This precise timing is crucial for developing the complex flavors and aromas that will eventually make their way into your instant coffee.

- The Maillard reaction: As the beans roast, they undergo a chemical process known as the Maillard reaction. This is where sugars and amino acids in the beans interact, creating hundreds of different flavor compounds. It’s like a symphony of taste being composed right before our eyes!

- Roast levels: Manufacturers can adjust their roasting profiles to achieve light, medium, or dark roasts. For flavored instant coffee, a darker roast is often preferred. Why? Dark roasts tend to have a more robust flavor that can stand up to the addition of flavorings and survive the subsequent processing steps.

- Moisture control: Roasters must carefully monitor the beans’ moisture content. Too much moisture can affect shelf life and hinder the efficiency of later steps like grinding and extraction.

Explore more: A Complete Guide to Essential Coffee Roaster Equipment

The roasting process is truly where science meets art. Master roasters use their expertise and state-of-the-art technology to coax out the perfect flavor profile for each batch of beans. It’s a delicate balance of time, temperature, and technique that sets the foundation for the instant coffee’s taste.

Industrial roasters are used, which can handle large quantities of beans

As the roasted beans cool, they’re ready for the next exciting step in their journey to becoming flavored instant coffee. But before we grind them up, take a moment to appreciate the complexity of this process. From the careful selection of beans from around the world to the precise art of roasting, every step so far has been crucial in developing the flavor that will eventually dissolve in your cup.

Liquid Gold: Creating the Coffee Extract

Now that we have our perfectly roasted beans, it’s time to unlock their flavor potential and transform them into a concentrated coffee extract. This process is crucial as it forms the base for our flavored instant coffee.

1. Grinding – Breaking It Down

The first step in creating our coffee extract is to grind those beautifully roasted beans. But this isn’t your average morning grind – we’re talking industrial-scale precision here.

- Coarse is key: Unlike the fine grind you might use for espresso, instant coffee manufacturing requires a coarser grind. Why? A coarser grind allows for better solubility in the final product, ensuring that your instant coffee dissolves quickly and completely when you add hot water.

- Consistency is crucial: Imagine massive industrial grinders, such as hammer mills or roller mills, working tirelessly to transform whole beans into a uniform coarse powder. This consistency is vital for even extraction and a high-quality final product.

- Surface area science: By grinding the beans, we’re increasing their surface area. This might sound technical, but it’s actually pretty simple – more surface area means better extraction of all those delicious flavors and aromas we developed during roasting.

Coffee grains vs. grinded

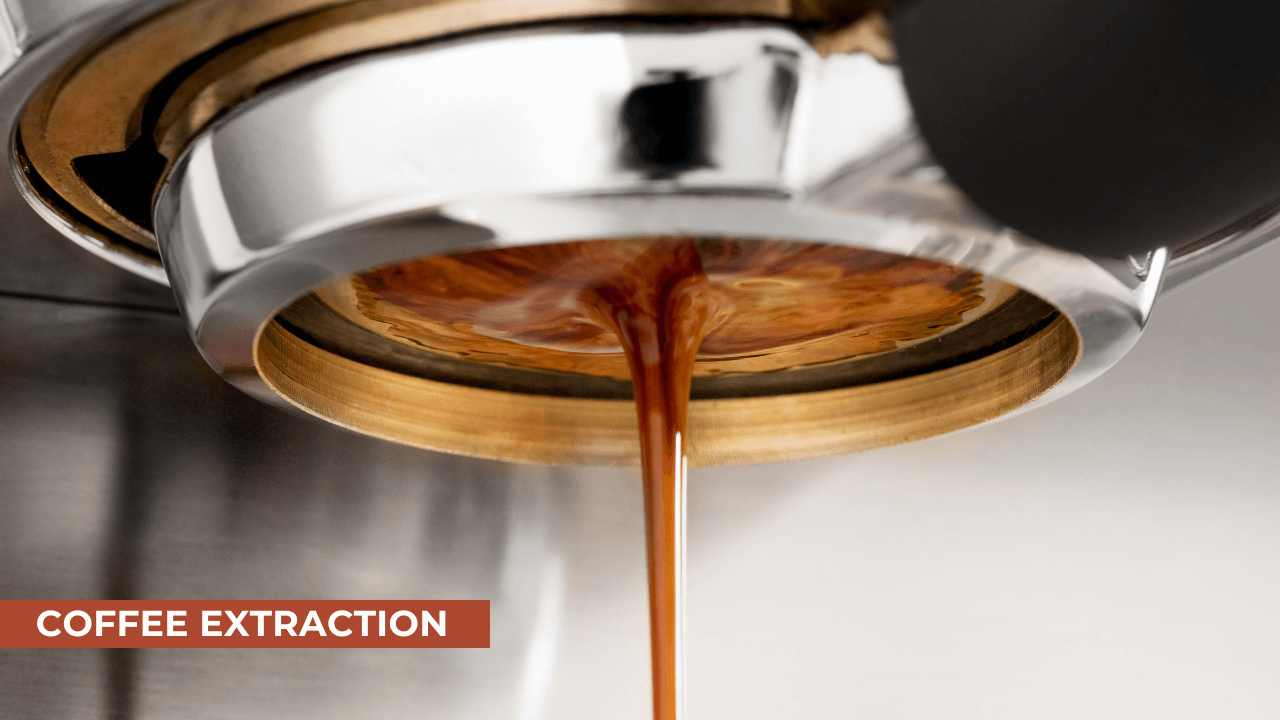

2. Extraction – Drawing Out the Essence

With our beans ground to perfection, it’s time for the real magic to happen – extraction. This is where we coax all those complex flavors and aromas out of the ground coffee and into a liquid form.

- Hot water heroes: The extraction process typically uses hot water, heated to around 90-95°C (194-203°F). This temperature range is ideal for extracting the soluble compounds that give coffee its characteristic taste and smell.

- Time is flavor: The extraction process can take anywhere from 15 to 30 minutes, depending on the desired strength and flavor profile. It’s a delicate balance – too short, and you miss out on flavor; too long, and you risk over-extraction and bitterness.

- Steam power: Many manufacturers use a steam extraction method. Picture a large coffee maker, but instead of dripping into a pot, the coffee is collected as a concentrated extract. This method is particularly effective at capturing those volatile compounds responsible for coffee’s irresistible aroma.

- Separation anxiety: Once the extraction is complete, we need to separate the liquid gold (our coffee extract) from the spent grounds. This is typically done using advanced filtration methods like centrifugation or pressure filtration.

The result? A rich, concentrated coffee extract that captures the essence of our carefully selected and roasted beans. But we’re not done yet – this extract is about to get a flavor makeover!

[Illustrated] The ground coffee is put through an extraction process

3. Flavoring – Adding the Extra Oomph

Now comes the part that transforms our coffee extract into the flavored instant coffee we know and love. It’s time to add those delicious flavors!

- Flavor fusion: The liquid coffee extract is thoroughly mixed with liquid flavoring ingredients. Think classic favorites like chocolate, vanilla, or caramel, but don’t stop there – the world of coffee flavoring is vast and ever-expanding!

- Mixing mastery: Achieving the perfect flavor balance is both an art and a science. Manufacturers use precise ratios to ensure consistency across batches. They might even employ emulsifiers to help integrate the flavors evenly throughout the coffee extract.

- Natural vs. artificial: Depending on the product line, manufacturers may use natural flavorings derived from real food sources or artificial flavors created in a lab. Each has its advantages in terms of cost, consistency, and intensity.

- Trend-setters: The choice of flavors often reflects current market trends and consumer preferences. Today’s coffee drinkers might be craving classic vanilla one year and exotic cardamom the next!

- Frozen with a twist: In some processes, the flavored coffee mixture is frozen in the presence of an inert gas like nitrogen. This expansion creates a consistent texture that will translate into the final product.

At this point, we have a flavorful, concentrated coffee mixture that’s bursting with aroma and taste. But it’s still in liquid form – not very convenient for your kitchen cupboard, is it? That’s where our next step comes in.

The Drying Process: From Liquid to Powder

We’ve arrived at a critical juncture in our flavored instant coffee manufacturing journey. Our carefully crafted, flavor-infused coffee extract is ready for its final transformation – from liquid to powder. This step is where science truly shines, employing advanced techniques to preserve flavor while creating a convenient, shelf-stable product.

1. Freeze Drying: The Cold Approach

Freeze drying is like a magic trick performed by mother nature herself, with a little help from some high-tech equipment. Here’s how it works:

- Flash Freezing: The flavored coffee mixture is rapidly frozen at extremely low temperatures. Imagine tiny ice crystals forming, locking in all those delicious flavors and aromas.

- Vacuum Chamber: The frozen coffee is placed in a vacuum chamber. This is where things get really interesting!

- Sublimation: Under specific pressure and temperature conditions, the ice in the coffee mixture sublimates. This means it transitions directly from a solid to a gas, bypassing the liquid phase entirely. It’s like watching ice cubes disappear into thin air!

- Collecting the Vapor: As the ice sublimates, it’s collected as water vapor, leaving behind a dry, porous coffee structure that retains its original shape.

- Final Drying: Any remaining moisture is removed through a process called secondary drying.

The result? A lightweight, flavor-packed powder that dissolves easily in water. Freeze drying is prized for its ability to preserve the coffee’s original flavor and aroma compounds, giving you a cup that’s remarkably close to freshly brewed coffee.

2. Spray Drying: The Heat Approach

While freeze drying is excellent for preserving flavor, spray drying offers speed and efficiency. Here’s a peek into this high-speed process:

- Atomization: The liquid coffee extract is sprayed into a fine mist of tiny droplets. Picture a super-fine coffee rain!

- Hot Air Chamber: These droplets are sprayed into a chamber filled with hot air, typically at temperatures between 150-300°C (302-572°F).

- Evaporation: As the droplets fall through the hot air, the water rapidly evaporates, leaving behind tiny particles of dried coffee.

- Collection: The dried coffee particles are collected at the bottom of the chamber.

Spray drying is faster than freeze drying and can handle larger volumes, making it a popular choice for large-scale production. However, it can result in some loss of volatile compounds, which is why manufacturers often use a combination of techniques or add additional flavorings to enhance the final product.

Unlock Consistent Quality: ExploreVNT’s Instant Coffee Spray Dryer

3. The Importance of Moisture Control

Regardless of the drying method used, controlling moisture content is crucial. The goal is to achieve a moisture content of less than 5%, as per standard health regulations. This low moisture content is essential for several reasons:

- Shelf Stability: Low moisture prevents microbial growth, ensuring your instant coffee stays fresh for months.

- Dissolvability: The right moisture level ensures your coffee dissolves quickly and completely in hot water.

- Flavor Preservation: Excess moisture can lead to flavor degradation over time.

Imagine teams of quality control experts, armed with high-tech moisture meters, carefully testing each batch to ensure it meets these exacting standards.

3. The Final Product

Whether freeze-dried or spray-dried, the end result is a dry, powdered form of flavored instant coffee. This powder retains much of the coffee’s original flavor and aroma compounds, along with the added flavorings we introduced earlier.

Drying is the critical process that transforms the liquid coffee extract into a instant coffee powder

But our journey isn’t over yet! This carefully crafted powder now needs to pass a battery of quality control tests before it can be packaged and sent out into the world. In our next section, we’ll explore the rigorous quality control measures that ensure every jar or sachet of flavored instant coffee meets the high standards coffee lovers expect.

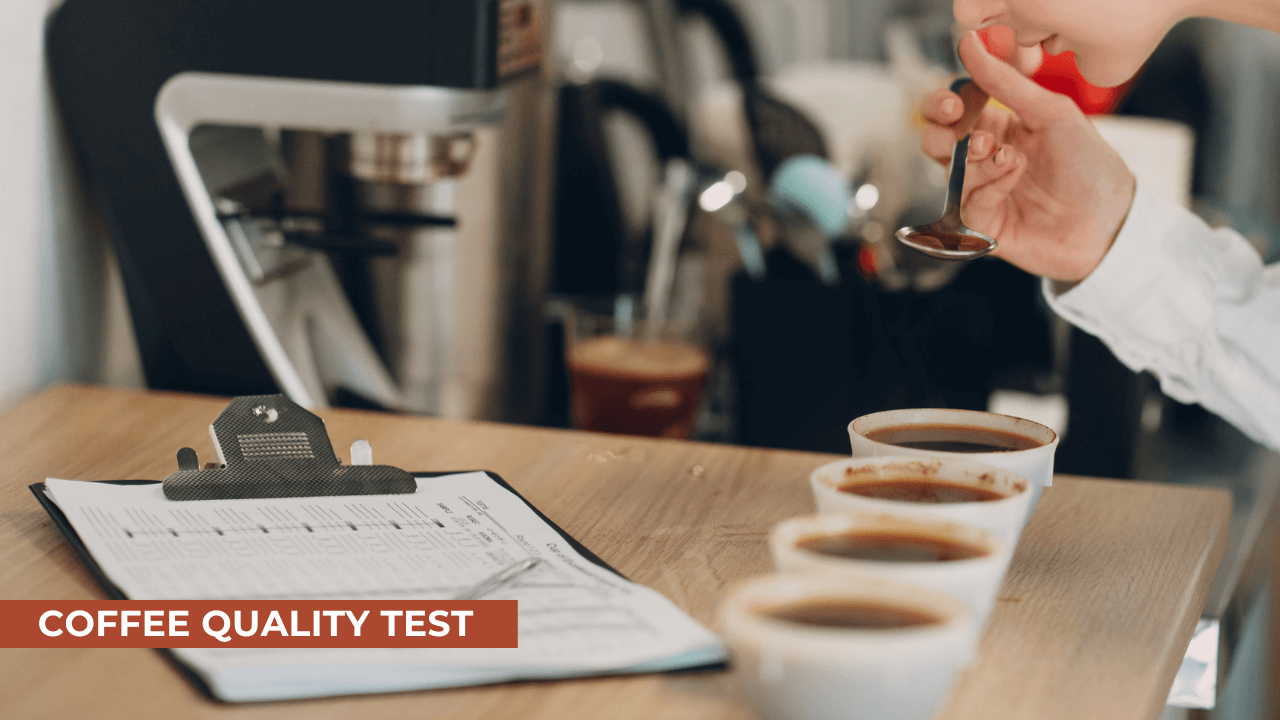

Quality Control

As our flavored instant coffee nears the end of its manufacturing journey, it faces perhaps its most critical challenge: quality control. This stage is all about ensuring that every granule of coffee meets the high standards set by the manufacturer and expected by discerning coffee lovers like you.

1. Sensory Evaluation: The Human Touch

While machines and technology play a crucial role in coffee production, there’s no replacing the human senses when it comes to evaluating flavor and aroma. Here’s how it works:

- Expert Panels: Trained sensory panels, often composed of professional coffee tasters, evaluate samples from each batch.

- Cupping Sessions: These experts participate in cupping sessions, where they assess various aspects of the coffee, including:

- Aroma: The scent of the dry powder and the brewed coffee

- Flavor: The taste profile, including the added flavoring

- Body: The mouthfeel and thickness of the brewed coffee

- Aftertaste: The lingering flavors after swallowing

Imagine a room filled with expert tasters, their noses buried in cups of freshly brewed instant coffee, scribbling notes and comparing impressions. It’s like a wine tasting, but for coffee enthusiasts!

Regular sensory evaluations are conducted by trained panels to assess flavor, aroma, and overall quality

2. Chemical Testing: The Scientific Approach

While human senses are invaluable, they’re backed up by rigorous scientific testing. Here’s what goes on in the lab:

- Caffeine Content: Ensuring consistent levels of caffeine from batch to batch.

- Acidity Levels: Monitoring pH levels to maintain flavor balance.

- Moisture Content: As mentioned earlier, keeping moisture below 5% is crucial for product stability.

- Solubility Testing: Measuring how quickly and completely the coffee dissolves in both hot and cold water.

Picture state-of-the-art laboratories with gleaming equipment, where white-coated technicians carefully measure and analyze samples, ensuring that every batch meets exacting standards.

3. Visual Inspection: Judging a Coffee by Its Cover

While taste is paramount, appearance matters too. Quality control teams assess:

- Color Consistency: Ensuring a uniform color that meets product specifications.

- Granule Size: Checking for consistency in particle size, which affects dissolution.

- Clumping: Looking for any unwanted clumping that could affect the user experience.

4. Flavor Profile and Longevity

For flavored instant coffee, striking the perfect balance between coffee taste and added flavors is an art backed by science. Experts employ sophisticated techniques like gas chromatography to analyze volatile compounds, ensuring each batch hits the right flavor notes. But great taste isn’t just for day one—manufacturers want to guarantee your coffee tastes fantastic whether you open it today or months down the line. That’s where accelerated shelf-life tests come in. These simulations mimic long-term storage conditions, pushing the product to its limits to ensure it maintains its quality throughout its expected shelf life. It’s a dual approach that marries the immediate sensory experience with long-term satisfaction, embodying the manufacturer’s commitment to delivering consistently delightful coffee moments, cup after cup.

Packaging and Storage: Preserving Perfection

After passing rigorous quality control measures, our flavored instant coffee is ready for its final step before reaching your cup: packaging. This stage is crucial for preserving the coffee’s flavor, aroma, and quality during transportation and storage.

5.1 The Packaging Challenge

Instant coffee presents unique packaging challenges due to its hygroscopic nature – it readily absorbs moisture from the air. This property, while great for quick dissolution in your mug, can spell disaster if not properly managed during storage.

5.2 Packaging Solutions

To combat the hygroscopic nature of instant coffee and preserve its quality, manufacturers employ several clever packaging strategies:

- Airtight Containers: Jars with tight-sealing lids are a popular choice for instant coffee. These glass or plastic containers create a barrier against moisture and air, preserving the coffee’s freshness.

- Foil Pouches: For single-serve portions or larger quantities, multilayer foil pouches are often used. These pouches typically consist of layers of plastic, aluminum, and sometimes paper, creating an effective barrier against moisture, oxygen, and light.

- Nitrogen Flushing: Before sealing, many manufacturers use a technique called nitrogen flushing. This process replaces the air inside the package with nitrogen gas, an inert gas that doesn’t react with the coffee. This helps prevent oxidation, preserving flavor and extending shelf life.

5.3 The Packaging Process

Picture a state-of-the-art packaging facility:

- Controlled Environment: The packaging area is kept at low humidity to prevent moisture absorption during the process.

- Precise Filling: Automated machines precisely measure and dispense the instant coffee into containers or pouches.

- Sealing: Advanced sealing technologies ensure an airtight closure, whether it’s heat-sealing a foil pouch or twisting on a jar lid.

- Labeling: Each package is labeled with product information, brewing instructions, and that all-important expiration date.

5.4 Storage Considerations

Proper storage is crucial for maintaining the quality of flavored instant coffee:

- Temperature Control: Instant coffee is best stored in a cool, dry place. Extreme temperatures can affect flavor and cause clumping.

- Light Protection: Exposure to light can degrade flavors over time, which is why opaque packaging or storage in a dark cupboard is recommended.

- Moisture Avoidance: Always use a dry spoon when scooping out coffee, and close the container tightly after each use to prevent moisture intrusion.

5.5 Shelf Life

Thanks to these careful packaging and storage methods, flavored instant coffee typically has a shelf life of about 12-18 months when unopened. Once opened, it’s best consumed within a few months for optimal flavor.

Consumer Testing: The Ultimate Judge

It is essential to do consumer testing to make sure the developed product satisfies market demands and tastes. This could involve:

- Blind Taste Tests: Where consumers compare the new product against existing options.

- Surveys and Feedback: Gathering opinions on flavor, aroma, and overall satisfaction.

- Purchase Intent Studies: Gauging how likely consumers are to buy the product.

After statistical analysis of the test results, the product can be refined in the final stages before going into mass manufacturing, yielding insightful information. Decisions on product development are also supported by the confidence the consumer testing results bring.

Ready to elevate your business’ Instant Coffee Manufacturing Process? Contact our experts today!

Conclusion

As we’ve explored the fascinating world of flavored instant coffee manufacturing, it’s clear that this convenient beverage is the result of a complex, carefully orchestrated process. From the selection of premium beans to the final packaging, every step is designed to deliver a cup of coffee that’s not just quick and easy, but also satisfying and flavorful. The journey we’ve traced – from harvesting and roasting to extraction, flavoring, drying, and packaging – showcases the perfect blend of traditional coffee craftsmanship and cutting-edge food science. It’s a testament to human ingenuity, driven by our never-ending quest for the perfect cup of coffee that fits our busy, modern lifestyles.

Play Now: – 1099 Tax calculator

The next time you stir a spoonful of flavored instant coffee into your mug, take a moment to appreciate the journey it’s been on. From sun-drenched plantations to high-tech processing facilities, from expert tasters to lab technicians, countless hands and minds have contributed to making your quick coffee break a flavorful experience.