Achieving the perfect roast and unlocking the full potential of your coffee beans requires the right equipment. Whether you’re a seasoned coffee roaster or just starting out, understanding the crucial role of coffee roaster equipment in the roasting process is essential for consistent and high-quality results. In this comprehensive guide, we’ll explore the essential coffee roaster equipment that every roastery needs, whether operating on an industrial or commercial scale.

Introduction to Coffee Roaster Equipment

Coffee roaster equipment plays a crucial role in the coffee roasting process, enabling professionals to create a wide range of coffee flavors and profiles. These essential tools, such as the roaster, airflow control mechanism, and temperature gauge, help coffee roasters achieve precision and consistency in their roast batches.

What is Coffee Roaster Equipment?

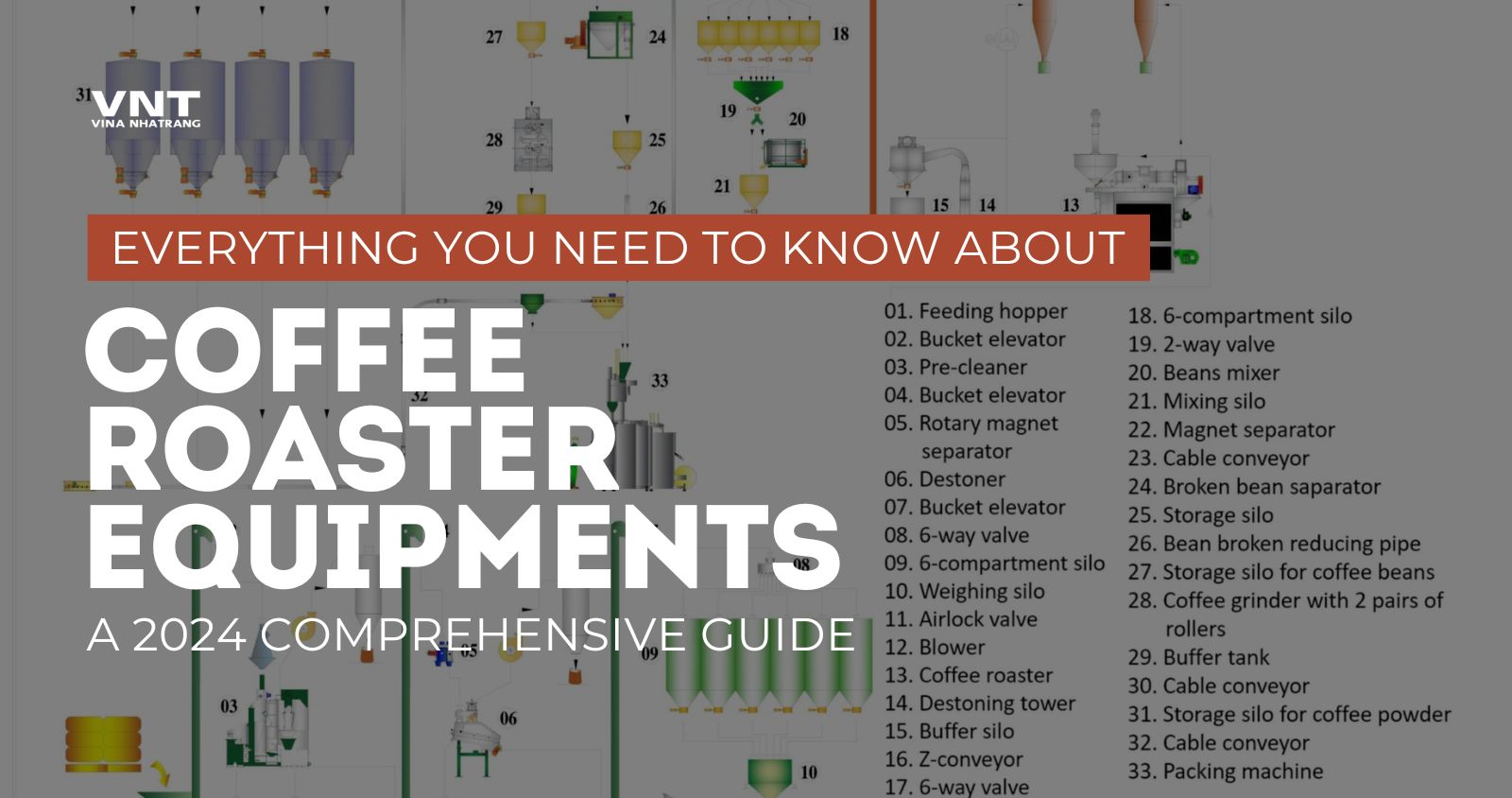

Coffee roaster equipment consists of various specialized machines and components that work together to facilitate the coffee roasting process. From cleaning and sorting the green coffee beans to roasting them to perfection, each piece of equipment plays a crucial role in ensuring a smooth, efficient, and consistent operation.

Before diving into the specifics, let’s familiarize ourselves with the key components that make up a typical coffee roasting setup:

- The roaster itself is the core piece of equipment in coffee roasting – a specialized machine designed to roast the green beans to the desired color, aroma, and flavor profile, transforming them into the aromatic and flavorful roasted beans that coffee enthusiasts crave. Different types of roasters, ranging from small batch roasters to large industrial ones, can greatly impact the final flavors and characteristics of the coffee.

- Airflow control mechanisms play a crucial role in managing the circulation of hot air during the roasting process. By adjusting the airflow, roasters can influence the rate of heat transfer and control the development of flavors in the beans. This control helps to create a consistent and even roast.

- Temperature gauges provide real-time information about the temperature inside the roaster, allowing roasters to monitor and adjust the temperature at different stages of the roasting process. This is vital for achieving specific flavor profiles, such as increasing or decreasing the temperature during the first crack or controlling heat increase during later stages of roasting.

- In addition to these essential tools, there are other equipment options available to coffee roasters. Bean loaders facilitate the efficient movement of beans in and out of the roaster; agitators ensure uniform heat distribution, and cooling trays or systems quickly cool down the roasted coffee beans to prevent over-roasting.

Explore VNT’s Commercial Coffee Roasters with batch size ranging from 1kg to 30kg.

Importance of Coffee Roaster Equipment:

Investing in high-quality coffee roaster equipment is essential for any successful roastery, regardless of its scale or size. The importance of these specialized machines and components cannot be overstated, as they directly impact the quality, consistency, and efficiency of the roasting process, ultimately influencing the final product.

- Proper cleaning and sorting of green beans: Pre-cleaners, destoners, and rotary magnet separators ensure that the green beans are free from debris, stones, and metal particles, preventing damage to the roasting equipment and maintaining the purity of the final product.

- Precise batch control: Weighing silos and bucket elevators enable accurate measurement and efficient transportation of the green beans, ensuring consistent batch sizes and roasting results.

- Optimal roasting conditions: Coffee roasters are designed to provide precise control over temperature, airflow, and roasting time, allowing roasters to achieve their desired flavor profiles consistently.

- Efficiency and productivity: Well-designed roasting equipment, including auxiliary components like cooling trays and packaging machines, streamlines the entire roasting process, maximizing efficiency and productivity.

- Quality assurance: By investing in high-quality roaster equipment, roasteries can maintain strict quality control measures, ensuring that every batch of roasted beans meets their rigorous standards.

- Moreover, the right equipment can also contribute to energy efficiency, reducing operational costs and minimizing the environmental impact of the roasting process.

By understanding the function and capabilities of each piece of equipment, roasteries can consistently deliver exceptional coffee experiences to their customers, solidifying their reputation and fostering long-term success in the industry.

Explore our in-depth guide on Choosing the right coffee roaster equipment for your business.

Types of Coffee Roaster Equipment

Pre-cleaners – The Gatekeepers of Quality

In the pursuit of crafting exceptional coffee, meticulous attention to detail is paramount, and this journey begins even before the roasting process commences. Green coffee beans often harbor impurities, debris, or foreign objects that could tarnish the final product’s flavor and quality. Fortunately, pre-cleaners serve as the diligent guardians, meticulously safeguarding the integrity of the beans.

These specialized machines, the unsung heroes of the coffee roasting industry, stand as the first line of defense against potential contaminants. With their advanced technologies and intricate designs, pre-cleaners meticulously separate undesirable elements from the precious coffee beans, ensuring a pristine foundation for the roasting process.

Key benefits of pre-cleaners:

- Ensure that only the purest beans progress to the roasting stage, laying the foundation for a superior final product.

- Extend the lifespan of costly machinery.

- Streamline the coffee roasting operations.

- Contribute to the repeatable quality and flavor profiles that coffee connoisseurs demand.

Investing in high-quality pre-cleaners is not merely a precautionary measure; it is a commitment to excellence. By ensuring that only the purest beans progress to the roasting stage, roasters can confidently embark on the next phase of the journey, secure in the knowledge that their efforts will yield a product of uncompromising quality.

Bucket Elevators – Streamlining Bean Transportation

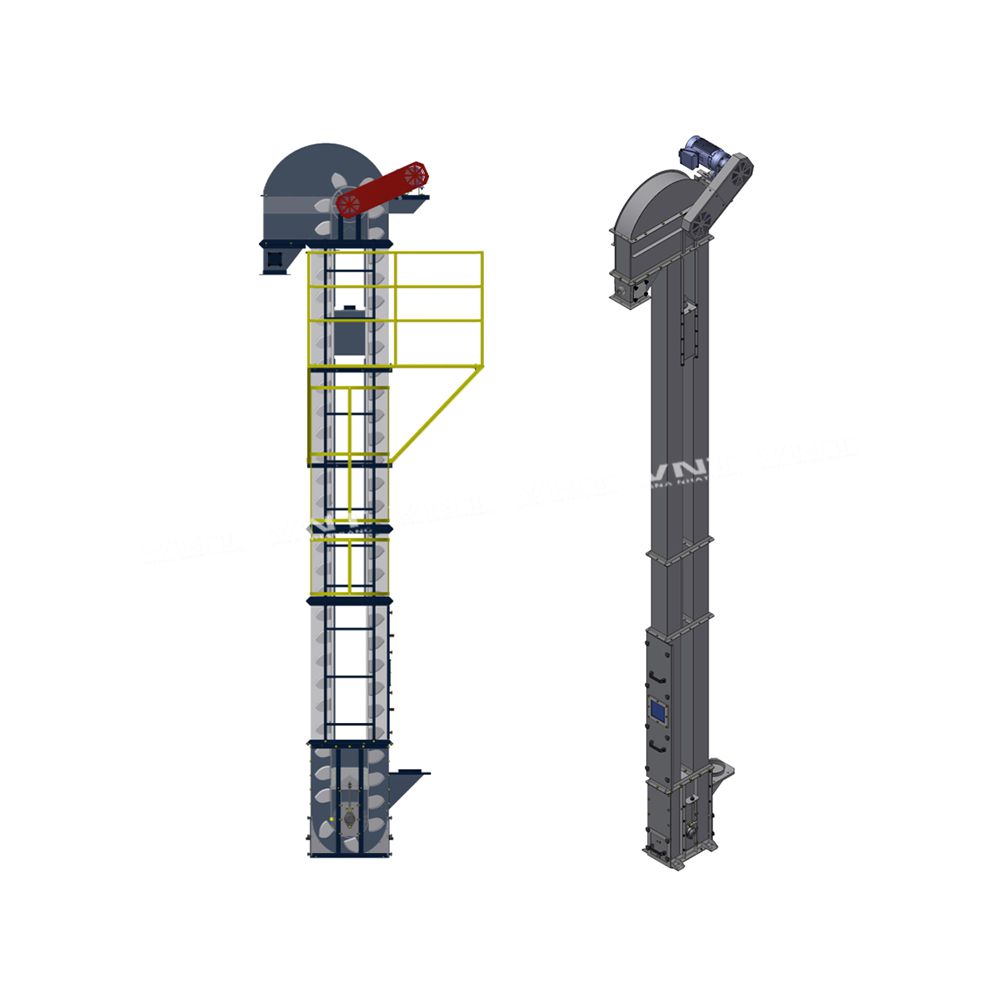

Once the beans have been thoroughly cleaned, they need to be transported to the next stage of the roasting process – and that’s where bucket elevators come into play. These versatile conveyor systems are designed to move large quantities of beans smoothly and efficiently, minimizing the risk of spillage or cross-contamination.

Bucket elevators are not only essential for transporting beans between different processing stages but also play a crucial role in maintaining a continuous flow throughout the entire roasting operation. By seamlessly integrating with other equipment, bucket elevators help streamline the production process, improving overall efficiency and reducing downtime.

Key benefits of bucket elevators:

- Efficient conveyor systems for transporting coffee beans between processing stages.

- Prevent damage that could occur with other conveying methods like augers or pneumatic systems.

- Maximize productivity and efficiency.

From the initial cleaning stage to the final packaging, bucket elevators are the unsung heroes that keep the coffee roasting process flowing seamlessly, enabling roasters to focus on their craft and deliver exceptional quality with every batch.

Rotary Magnet Separators – Safeguarding Quality and Equipment

Even after the pre-cleaning stage, there is a possibility that some metal contaminants may still be present in the bean batch. This is where rotary magnet separators shine, using powerful magnetic forces to remove any residual metal fragments that could potentially damage downstream equipment or compromise the quality of the final product.

These separators are designed to work in tandem with other sorting and grading equipment, ensuring that only the highest-quality beans make it to the roasting stage. By eliminating the risk of metal contaminants, rotary magnet separators help protect the integrity of the roasting process and the longevity of your equipment.

Key Benefits of rotary magnet separators:

- Protect expensive roasting equipment from damage caused by metal contaminants.

- Enhance quality control by removing potential contaminants.

- Seamlessly integrates with other sorting and grading equipment.

- Minimizes risk of costly equipment repairs and downtime.

By incorporating rotary magnet separators into their operations, coffee roasters can have peace of mind, knowing that their equipment and final product are shielded from the potentially detrimental effects of metal contaminants.

Destoners – Precision Removal of Dense Contaminants

While pre-cleaners and magnet separators handle the removal of debris and metal contaminants, destoners play a vital role in separating dense materials, such as stones or small rocks, from the coffee beans. Even a single stone can cause significant damage to the roasting drums or negatively impact the roast profile, making destoners an indispensable part of any coffee roasting operation.

Destoners use a combination of advanced technologies, including air flow and vibration, to effectively separate dense materials from the lighter coffee beans. By ensuring that only the highest-quality beans make it to the roasting stage, destoners contribute to the consistent production of superior coffee products.

Key benefits of destoners:

- Protect roasting drums and equipment from damage.

- Prevent off-flavors or inconsistencies from contaminants.

- Ensure uniformity and quality of roasted bean batches.

- Increase efficiency by removing need for manual sorting.

By meticulously removing even the smallest dense impurities, destoners play a crucial role in safeguarding the integrity of the roasting process.

Weighing Silos – Precision Portioning for Perfection

Accurate weighing is crucial for achieving consistent roasting results and delivering a product that meets the discerning tastes of your customers. Weighing silos play a vital role in this process, precisely measuring the weight of the green coffee beans before they enter the roasting stage.

These specialized silos not only ensure accurate weighing but also serve as temporary storage units, allowing for a smooth and continuous flow of beans throughout the roasting process. Many modern weighing silos are equipped with advanced control systems that enable seamless integration with other equipment, further enhancing the efficiency and automation of your roasting operations.

Key benefits of weighing silos:

- Precise weighing for optimal bean-to-batch ratio and consistent roast profiles.

- Temporary storage capabilities for seamless workflow.

- Advanced control systems for enhanced automation and real-time monitoring.

- Integration with other equipment for streamlined operations.

In the pursuit of coffee roasting excellence, weighing silos stand as sentinels of precision, guardians of quality, and enablers of efficiency. By ensuring accurate portioning and seamless integration, these indispensable vessels play a vital role in crafting the perfect roast, time and time again.

Coffee Roasters – The Alchemists’ Crucible

At the core of every coffee roasting facility lies the roaster itself – a specialized piece of equipment that transforms simple green beans into the rich, aromatic coffee we know and love. The market offers a diverse range of roaster types, each with its unique characteristics and capabilities, catering to the specific needs of different roasting businesses.

Drum roasters, for instance, are a popular choice for their ability to produce consistent results and handle various batch sizes. Fluid bed roasters, on the other hand, prioritize energy efficiency and precise control over the roasting process. Tangential roasters offer a unique approach, using a combination of centrifugal force and hot air to achieve highly efficient and even roasting.

Key considerations:

- Batch size and production capacity requirements

- Energy efficiency and environmental sustainability

- Level of control and roast profiling capabilities

- Consistency and repeatability of flavor profiles

- Integration with other equipment and automation systems

When selecting a coffee roaster, all factors should be carefully considered. Many modern roasters come equipped with advanced roast profiling software, allowing for intricate adjustments and data analysis, ensuring consistent and repeatable flavor profiles.

Consult with our experts and discover the perfect coffee roaster to your unique needs.

Auxiliary Equipment

While the equipment mentioned above forms the backbone of any coffee roasting operation, several auxiliary components play crucial supporting roles. Cooling trays or bins are essential for rapidly cooling the roasted beans, preserving their flavor and preventing over-roasting. Chaff collectors help remove the chaff (outer skin) released during the roasting process, maintaining a clean and efficient working environment.

Packaging equipment is also a critical component, ensuring that the freshly roasted beans are sealed and protected from environmental factors that could compromise their quality and aroma.

Conclusion

In conclusion, investing in high-quality coffee roaster equipment is essential for achieving consistent and high-quality roast batches. The right equipment, such as the roaster, airflow control mechanisms, and temperature gauges, plays a crucial role in creating diverse coffee flavors and profiles. From drum roasters to air roasters, each type of equipment has its advantages and considerations, ensuring versatility and efficiency in the roasting process. Additionally, factors like capacity, control systems, heating source, and cooling mechanism should be considered when selecting coffee roaster equipment. By understanding the function and capabilities of each piece of equipment, coffee roasters can deliver exceptional coffee experiences, maintain strict quality control measures, and foster long-term success in the industry.