Picture this: you’ve just harvested a bountiful crop of grain, the result of months of hard work and careful cultivation. But your job isn’t done yet. In fact, one of the most crucial steps in ensuring the quality and longevity of your harvest is still to come – the drying process. This is where agricultural dryers come into play, serving as indispensable tools for modern farmers.

But why is drying so important in agriculture? And what exactly are these agricultural dryers? Whether you’re a seasoned farmer looking to upgrade your equipment or a curious newcomer to the world of agriculture, this comprehensive guide will walk you through everything you need to know about agricultural dryers and their vital role in crop management.

What is an Agricultural Dryer?

At its core, an agricultural dryer is a piece of equipment designed to remove excess moisture from harvested crops, particularly grains like corn, wheat, and rice. But it’s so much more than just a fancy dehumidifier. Think of it as a guardian of your harvest, protecting your crops from spoilage, mold, and quality degradation.

The importance of proper drying can’t be overstated. Crops that are too moist are susceptible to fungal growth, insect infestation, and even spontaneous combustion in storage. On the flip side, over-drying can lead to cracking and reduced nutritional value. It’s a delicate balance, and that’s where agricultural dryers shine.

There are two main types of agricultural dryers you’ll encounter in the field (pun intended):

- Mobile Dryers: These are the versatile workhorses of the drying world. They can be moved from one location to another, making them ideal for farms with multiple fields or for contractors who provide drying services.

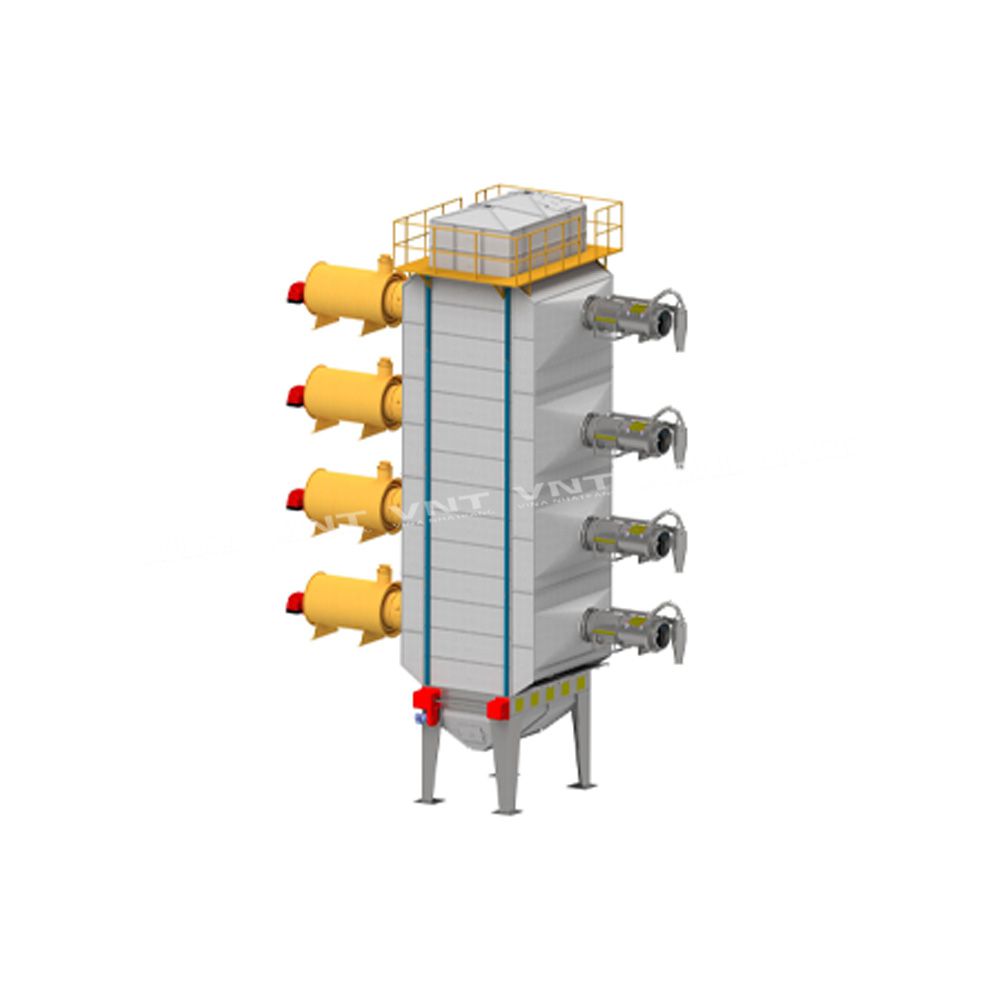

- Tower Dryers: As the name suggests, these are stationary units that stand tall and proud on the farm. They’re typically used for larger operations with centralized grain handling systems.

Both types of dryers share some common components, with the two most crucial being:

- The Head: This is the brain of the operation, housing the control systems and often the heating elements.

- The Drying Cylinder: This is where the magic happens – the actual chamber where the grain is dried.

Explore our full lineup of Agricultural Drying Systems HERE.

Operation of an Agricultural Dryer

Now, let’s dive into the nitty-gritty of how these marvels of agricultural engineering actually work. The basic principle is simple: use heat and airflow to evaporate excess moisture from the grain. But as with many things in farming, the devil is in the details.

Know More:- industrial coffee grinder | commercial coffee roaster machine | wood chip burner

The drying process involves partially separating water from the grain through evaporation. It’s a bit like blow-drying your hair, but on a much larger and more precisely controlled scale. The grain is exposed to a stream of heated air, which causes the moisture within the kernels to evaporate and be carried away.

This process typically unfolds in four distinct phases:

- Loading: The wet grain is fed into the dryer. This can be done continuously or in batches, depending on the type of dryer.

- Drying: Hot air is forced through the grain, removing moisture. The temperature and airflow are carefully controlled to ensure even drying without damaging the grain.

- Cooling: Once the desired moisture level is reached, the grain is cooled to prevent condensation when it’s moved to storage.

- Discharge: The dried and cooled grain is removed from the dryer, ready for storage or transport.

Here’s where we see a key difference between mobile and tower dryers. Mobile dryers typically operate on a discontinuous cycle, meaning they process one batch at a time. It’s like doing laundry – you load, dry, cool, and unload before starting the next batch.

Tower dryers, on the other hand, often use a continuous cycle. Imagine a tall cylinder with wet grain entering at the top, gradually moving downward as it dries, and exiting at the bottom. It’s more like a conveyor belt of drying, with a constant flow of grain moving through the system.

Advantages of Using an Agricultural Dryer

Now that we understand how these dryers work, let’s talk about why they’re so crucial for modern agriculture. The benefits of proper drying extend far beyond just removing moisture.

First and foremost, drying is essential for long-term storage. Properly dried grain can be stored for extended periods without risk of spoilage. This allows farmers to hold onto their harvest until market conditions are favorable, rather than being forced to sell immediately after harvest.

Proper drying preserves grain quality and prevents spoilage

Drying also plays a critical role in preserving cereal quality. By reducing moisture content, we prevent a host of potential issues:

- Aging: Excessive moisture can cause grain to deteriorate rapidly, reducing its value and nutritional content.

- Fermentation: Too much moisture can lead to unwanted fermentation, altering the grain’s properties and making it unsuitable for many uses.

- Toxin Development: Moist conditions are a breeding ground for fungi that can produce harmful mycotoxins.

But the advantages don’t stop there. Agricultural dryers can significantly boost productivity and profits. By allowing farmers to harvest earlier and at higher moisture contents, dryers extend the harvesting window. This can be a game-changer in regions with short growing seasons or unpredictable weather.

When it comes to choosing between mobile and tower dryers, each has its unique advantages:

- Mobile Dryers:

- Flexibility: Can be moved to where they’re needed most.

- Scalability: Ideal for farms that may need to adjust their drying capacity from year to year.

- Lower Initial Investment: Generally less expensive to purchase than tower dryers.

- Tower Dryers:

- Higher Capacity: Can handle larger volumes of grain continuously.

- Energy Efficiency: Often more efficient for large-scale operations.

- Integration: Can be seamlessly incorporated into existing grain handling systems.

The dryers we offer at Vina Nha Trang are designed to deliver all these benefits and more. Whether you’re looking for the flexibility of a mobile dryer or the high-capacity performance of a tower dryer, we have solutions to fit farms of all sizes. Check out our range of options HERE.

Precision Drying: New Digital Technologies and Innovative Applications

As with many aspects of agriculture, the world of grain drying is being revolutionized by digital technology. Today’s agricultural dryers are a far cry from the simple heated air blowers of yesteryear.

Modern dryers often come equipped with advanced sensors and control systems that allow for precise monitoring and adjustment of the drying process. These systems can track factors like grain moisture content, air temperature, and energy consumption in real-time.

Know More:- tower dryer | wood chip drying system | aroma recovery

But it doesn’t stop there. Some cutting-edge dryers are now incorporating artificial intelligence and machine learning algorithms. These smart systems can predict optimal drying parameters based on factors like grain type, initial moisture content, and even weather forecasts.

Another exciting development is the integration of renewable energy sources. Solar-powered dryers are becoming increasingly common, especially in remote areas or regions with unreliable power grids. There are even experiments with using biogas generated from agricultural waste to power dryers, creating a closed-loop system that enhances sustainability.

These technological advancements are not just about efficiency – they’re about quality. Precision drying allows farmers to achieve more consistent results, reducing the risk of over or under-drying and ensuring that every kernel meets the exact specifications required by buyers.

Ready to take your grain drying to the next level? REACH OUT NOW to our team of agricultural equipment experts for cutomized advice and information on the latest drying technologies.

Conclusion

As we’ve seen, agricultural dryers are far more than just tools for removing moisture from grain. They’re sophisticated pieces of equipment that play a crucial role in modern farming, impacting everything from harvest timing to crop quality and farmer profitability.

Whether you’re managing a small family farm or overseeing a large agricultural operation, investing in quality drying equipment can make a significant difference to your bottom line. It’s not just about preserving your harvest – it’s about preserving your options, giving you the flexibility to store your grain until market conditions are favorable.

As technology continues to advance, we can expect to see even more innovations in the field of agricultural drying. From AI-powered control systems to sustainable energy solutions, the future of grain drying looks bright indeed.

Remember, choosing the right dryer for your operation is a crucial decision that depends on various factors including your farm size, crop types, and specific needs. Don’t hesitate to reach out to agricultural equipment experts for personalized advice.