In the delicate dance of roasting, every bean tells a tale.

Mastering the roasting process is essential, yielding flavors that are transformative and complex within a coffee connoisseur’s discerning palate.

When evaluating an industrial coffee roaster, one contemplates its capacity, consistency, control, and the intricate technical specifications that ensure every batch meets the high standards expected.

Understanding Coffee Roasting

Roasting transforms green coffee into the aromatic brown beans we know and cherish. It is a balance between art and science, with the roaster imparting unique flavor profiles through thermal and chemical management.

As the beans are exposed to high temperatures, they undergo Maillard reactions and caramelization, essential for developing the complex flavors and aromas. Precision is crucial; roasters must judiciously manipulate time and temperature to curate the desired sensory experience.

The term “first crack” and “second crack” refer to distinct phases in the roasting process. They mark critical transitions in the beans’ development and are pivotal for roasters to gauge the roast degree.

Roasting Process Basics

The industrial roasting journey begins with the meticulous selection of green coffee beans, followed by an evenly executed roasting sequence. The goal is to unlock the beans’ full flavor potential while preserving quality.

During roasting, the temperature and time are tightly controlled, producing a spectrum of roast levels from light to dark. Each level impacts flavor and should align with the desired coffee profile.

Post-roasting operations include cooling and degassing—vital for the stabilization of roasted beans. Each step from roast initiation to packaging influences the coffee’s final character and cup quality.

Roaster Types Explained

Selecting an industrial coffee roaster is pivotal for achieving consistency and quality in coffee production.

- Drum Roasters: The most prevalent type, drum roasters roast coffee beans by tumbling them in a rotating drum heated either by direct or indirect flames.

- Fluid Bed Roasters: Utilizing hot air streams to roast coffee beans, they provide uniform heat distribution, usually resulting in a brighter acidity.

- Tangential Roasters: A subset of drum roasters with a unique airflow pattern, enhancing flavor development through meticulous thermal transfer.

- Centrifugal Roasters: An innovative approach where centrifugal force is used alongside hot air, delivering high uniformity and rapid roasting cycles.

- Hybrid Roasters: Combining methods, hybrid roasters offer flexibility in manipulating roast profiles, catering to diverse sensory attributes.

Each roaster type is equipped with specific mechanisms that influence bean movement, heat application, and airflow.

From boutique roasters to mass production, the machine type defines the roaster’s control over the roast profile and resultant flavor nuances.

Roasting Phases Overview

Roasting transforms green coffee beans into aromatic, flavorful brews through stages, beginning with drying, leading to the delicate Maillard reactions. Expertly modulating this process is crucial for flavor development and consistency across batches.

Drying initially reduces the moisture content within the beans, preparing them for chemical transformations. Without proper drying, the subsequent phases can be adversely affected, resulting in suboptimal flavor profiles.

As temperature rises, beans undergo the Maillard reaction, where sugars and amino acids create complex flavors. It’s a critical juncture (requiring precision monitoring) that greatly influences the roast’s character.

Following the Maillard phase, first crack signals the onset of significant structural bean changes. Gases expand, creating audible cracks as beans become lighter and porous, now primed to absorb heat more readily.

Complex caramelization reactions then develop richer, deeper flavors, though risk of char increases. It requires a roaster’s nuanced control to navigate this stage without overextending into bitterness or an acrid burn.

Finally, the roaster must cool the beans promptly to halt these reactions. Mastery over this phase ensures the preservation of a coffee’s distinct sensory profile, a skill paramount amongst adept roasters.

Selecting Your Roaster

The choice of a roaster is pivotal, encompassing operational capacity, thermal efficiency, and control systems—each aspect must align with your production goals and the quality aspirations of your coffee. Consideration for the roaster’s ability to consistently achieve desired flavor profiles is paramount, as variations in technology and design influence roast dynamics and bean development.

Roaster selection demands careful deliberation. Evaluate machine longevity, maintenance requirements, and overall return on investment. Precision and reliability are non-negotiable; the right roaster becomes the cornerstone for your coffee offerings’ excellence and consistency.

Capacity Needs

When assessing your capacity needs, it’s vital to consider both current demand and future scalability. A roaster that’s too small can bottleneck production, forcing roasting cycles to run incessantly, whereas one too large may be inefficient in terms of energy use and can lead to underutilization. Ideally, aim for a roaster that meets today’s needs while providing some room for growth.

To optimize for economic efficiency and quality control, choosing a roaster with the appropriate capacity is crucial. This will ensure that you can maintain a steady production flow, without incurring unnecessary overheads. Moreover, selecting a roaster that can handle slight increases in demand without maxing out immediately provides a buffer for business growth and the occasional spike in orders.

| Model | Capacity (Kg/H) | Gas consumption (Kg Gas / 100Kg) | Power consumption (Kwh) | Power supply |

| VNTR – 60 | 180 ÷ 240 | 2 ÷ 3 | 11 | 3 pha – 50 Hz |

| VNTR – 120 | 360 ÷ 480 | 2 ÷ 3 | 16.4 | 3 pha – 50 Hz |

| VNTR – 250 | 750 ÷ 1000 | 2 ÷ 3 | 20.5 | 3 pha – 50 Hz |

| VNTR – 600 | 2400 ÷ 3000 | 2 ÷ 3 | 68.5 | 3 pha – 50 Hz |

VNT’s Industrial Coffee Roaster Specification

Your facility’s throughput is a reflection of your capacity decisions. With the coffee market poised for continued expansion, especially considering the projected growth in both global consumption and premium coffee products through 2023 and beyond, selecting the right capacity from the outset is instrumental. This forward-looking approach will cushion you against both capacity-related bottlenecks and the need for premature equipment upgrades, which can be both disruptive and costly.

Budget Considerations

When amidst the procurement of an industrial coffee roaster, budget assessments must be meticulously calculated. Initially, one must consider the capital outlay against the projected return on investment for the selected machinery. The depreciation, potential resale value, and long-term operational costs also require careful consideration, as these factors significantly impact the total cost of ownership. Additionally, one must contemplate available financing or leasing options which may alleviate immediate financial burden.

Check out our detail guide on How much does a Industrial Coffee Roaster cost?

In the industrial roasting landscape, equipment price does not necessarily correlate with performance efficacy. It is paramount to evaluate not just the initial purchase cost, but also the maintenance expenses, energy consumption, and efficiency of the roaster over its lifespan. A cheaper upfront cost can be deceptive if the machine necessitates frequent repairs or consumes excessive power, leading to elevated operational costs that undermine any initial savings.

Furthermore, investing in a roaster with advanced technologies may present a higher initial cost but can lead to substantial savings over time. High-efficiency roasters with tighter environmental controls and reduced energy outputs can significantly curtail long-term costs. These machines often require less maintenance and are designed to meet stringent sustainability standards, which may qualify for government incentives, further offsetting the investment.

Lastly, when establishing a budget, consider that the choice of roaster affects the cost of ancillary equipment. For a seamless operation, items such as afterburners, destoners, and packaging systems might be necessary. The compatibility of these additional units with the roaster must be factored into the overall financial plan. Their inclusion can augment the functional capabilities of the roasting operation but will proportionally inflate the initial investment.

Thus, a thorough cost analysis that extends beyond the price tag of the roaster itself is indispensable. It is the comprehensive understanding of all related expenses – from energy use to auxiliary equipment and maintenance – that will ultimately determine the financial prudence of the acquisition.

Feature Comparisons

Comparing industrial coffee roasters, we assess several significant features critical to operational efficiency and bean quality.

- Capacity: Varies from a few kilograms to several hundred, impacting output volume.

- Heat Source: Options include gas, electricity, or wood, each with unique implications on flavor and operational costs.

- Control System: Determines the precision and repeatability of roasting profiles, with automation features enhancing consistency.

- Roasting Drum: Type and material affect heat transfer and bean agitation, influencing the roast character.

- Ventilation System: Essential for smoke evacuation and odour control, impacting environmental compliance and roast clarity.

- Cooling System: Speed of cooling affects bean quality, necessitating efficient cool-down mechanisms.

- Chaff Collection: Efficient chaff removal is central to safety and maintenance, dictating the frequency of cleaning cycles.

- Energy Efficiency: Directly affects operational costs and sustainability, with some roasters incorporating energy recovery systems.

Each feature can be a make-or-break factor depending on specific production goals and quality targets.

Meticulous comparison of these elements allows roasting facilities to align equipment choice with their strategic objectives, ensuring the roaster augments both the art and science of coffee roasting.

The Roasting Journey

The roasting journey begins with green coffee beans, raw and teeming with potential, which are introduced to the roaster—a crucible of transformation. Through meticulously controlled heat application and airflow management, the beans undergo a series of complex chemical reactions known as the Maillard reaction and caramelization, developing their characteristic flavors, aromas, and color. Mastery of this process demands a confluence of science and sensory skills, as the roaster must balance time and temperature to coax out the desired roast profile, ultimately defining the coffee’s final sensory attributes.

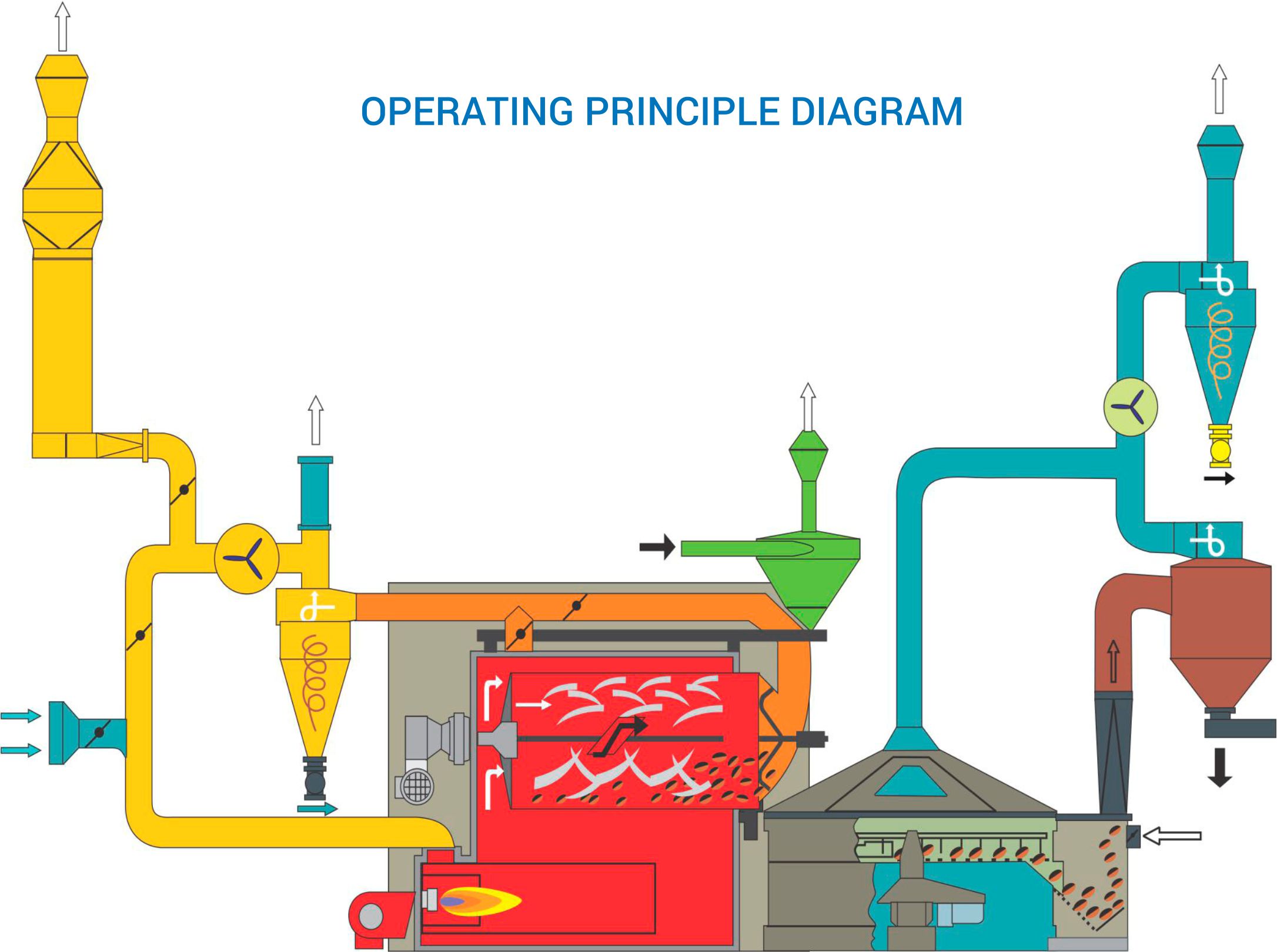

View our detail guide on How Industrial Coffee Roasters work?

Green Beans to Brown

Transforming green coffee beans into rich, brown roasted beans necessitates precise control and monitoring.

- Temperature Profiling: Profiling to determine the specific heat application for optimum flavor development.

- Duration of Roast: Tailoring the time to achieve the desired roast level from light to dark.

- Airflow Management: Regulating air to ensure even roasting and smoke evacuation.

- Cooling Procedures: Quenching the beans post-roast to halt the cooking process.

Precise manipulation of these variables is critical to quality.

The metamorphosis from green to brown is fundamental to flavor development, with each bean’s potential fully realized in the roast.

Flavor Development

It is imperative to underscore that flavor development is driven by the roasting process itself. The intricate reactions that occur within coffee beans are complex and multifaceted, as they are responsible for the creation of a tapestry of flavors that define the coffee’s profile. These reactions are initiated and controlled by the precise application of heat over time, manipulating the chemistry within each bean.

During the roasting process, a series of chemical reactions, predominantly the Maillard reaction and caramelization, are meticulously orchestrated to develop the full spectrum of flavors present in coffee. As proteins and sugars interact under intense heat, they form new flavor compounds, resulting in the rich and varied profiles that consumers covet. The roaster’s intimate knowledge about these reactions is paramount in adjusting roasting parameters to accentuate desired flavors, while mitigating the development of less favored profiles.

Moreover, the development of acidity, body, and aftertaste are all tied to this critical phase of production. As the coffee beans morph, the roaster must navigate roast degree and development time sensitively. The balance between preserving the beans’ origin flavors and embodying roast-induced characteristics is crucial and often requires deft adjustments to roasting protocols to achieve the desired outcome for each unique coffee.

For the connoisseur, flavor development represents the alchemy of converting green beans into complex sensory experiences. The roast profile, determined by the heat application, becomes the blueprint for unlocking the full potential held within each bean’s silence. This process, both scientific and artistic, necessitates a profound understanding of the behavioral nuances of different coffee varieties under heat. Only then can the roasting carefully choreograph the thermal environment to bring forth the best in flavor, aroma, and color – mastering the true craft of transformation.

Roasting Profiles

Roasting profiles articulate the nuanced control of heat and time applied to coffee beans during roasting.

- Light Roast: Features a lighter body with pronounced acidity, retaining most of the bean’s original flavor nuances.

- Medium Roast: Offers a balanced flavor profile, harmonizing acidity with the bean’s inherent sweetness and body.

- Medium-Dark Roast: Exhibits richer, darker flavors with some oil on the surface, and a slight bittersweet aftertaste.

- Dark Roast: Known for its bold, smoky flavors, this profile has a full body and often a pronounced bitterness.

Adapting these profiles requires precision, transforming the beans without compromising their distinctive characteristics.

Experts tirelessly refine these profiles, optimizing roast times and temperatures to achieve consistency and excellence.

Roasting Best Practices

To ensure consistency and quality in every batch, roasting best practices are foundational to the industrial coffee roasting process. It is pivotal to maintain rigorous control of roasting parameters, such as the rate of rise (RoR) and development time, which dictate the chemical reactions occurring within the beans. Expert roasters must also monitor environmental variables, including temperature and humidity, as these can affect batch uniformity. Above all, maintaining the cleanliness of the equipment is non-negotiable, as residual oils and particles from previous batches can taint the flavor profile. Mastery of these best practices is essential for producing coffee that meets the sophisticated palates of today’s consumers.

Temperature Control

Precision in temperature control is pivotal, as it oversees the rate of chemical reactions within the coffee beans during roasting. Temperature consistency ensures that the roast development is uniform across the batch, maintaining a harmonious balance between acidity, body, and flavor notes.

Temperature discrepancies can cause a batch to roast unevenly, resulting in an undesirable flavor profile.

Moreover, when temperature is meticulously managed, it safeguards the beans’ intrinsic qualities, ensuring that (despite the high temperatures required for transformation) the unique characteristics of each coffee origin are preserved.

An optimal roast curve is established by controlling the rate of temperature increase, adjusting the flame intensity, and monitoring the heat transfer to the beans, all of which are critical to flavor development.

Predictive software can aid in maintaining these precise temperature gradients, allowing for adjustments before any deviation impacts the roast quality or flavor.

Ultimately, the art of mastering a coffee roaster’s thermal control systems is central to achieving an exceptional roast profile. This mastery over thermal variables is what sets apart artisan roasting from mere processing.

Timing Precision

Achieving pinpoint timing in coffee roasting is paramount, as mere seconds can greatly influence the final cup quality. Roasters must constantly keep watch to attain the desired roast degree.

Each bean type has a unique time profile that corresponds to its optimal flavor release. Precision in timing ensures this potential is fully realized.

An overlooked aspect is the synchronization of time with temperature curves, allowing the coffee’s myriad compounds to develop properly. Inconsistencies here can skew taste, veiling the bean’s true essence.

The expertise in orchestrating the nexus of time, temperature, and bean characteristics is what enables roasters to extract the perfect balance and complexity from each lot. Roast profiles integrate period adjustments – akin to a conductor’s tempo shifts – which can radically transform the sensory narrative of the bean, an alchemy reliant on accurate timing.

Cooling and Storage

Upon completion of the roast, rapid cooling is integral to arrest the development process. Any delay can lead to over-roasting, compromising bean quality.

Effective cooling typically utilizes air or water quenching techniques to dissipate heat quickly.

Once cooled, the beans must be stored in a controlled environment to maintain their freshly roasted integrity. Factors such as air humidity, temperature, and light exposure can adversely affect flavor profiles.

Proper storage solutions range from airtight containers to one-way valve bags which prevent oxidation while allowing gases from the roasting process to escape. This is not only vital for preserving the attributes of the coffee, but it also primes the beans for peak flavor expression upon brewing, which often occurs days after roasting. Implementing such measures is synonymous with a commitment to excellence in coffee handling and ensures the highest standards of consumer experience.