Behind every delicious cup of coffee lies the art and science of coffee roasting. In the world of coffee production, industrial coffee roasters play a crucial role. These massive machines are designed to handle batch sizes ranging from 60kg to a staggering 250kg, ensuring a consistent supply of freshly roasted beans for coffee lovers worldwide. But how exactly do these industrial roasting giants operate? Let’s dive into the fascinating process.

What is an Industrial Coffee Roaster?

An industrial coffee roaster is a large-scale machine specifically engineered to roast substantial quantities of green coffee beans in a single batch.

Unlike commercial roasters used in specialty coffee shops or small coffee roasting companies setups, these industrial roasters can handle batch sizes from 60 kilograms up to an impressive 250 kilograms. This immense capacity allows industrial coffee operations to meet the ever-growing demand for freshly roasted beans efficiently.

| Model | Capacity (Kg/H) | Gas consumption (Kg Gas / 100Kg) | Power consumption (Kwh) | Power supply |

| VNTR – 60 | 180 ÷ 240 | 2 ÷ 3 | 11 | 3 pha – 50 Hz |

| VNTR – 120 | 360 ÷ 480 | 2 ÷ 3 | 16.4 | 3 pha – 50 Hz |

| VNTR – 250 | 750 ÷ 1000 | 2 ÷ 3 | 20.5 | 3 pha – 50 Hz |

| VNTR – 600 | 2400 ÷ 3000 | 2 ÷ 3 | 68.5 | 3 pha – 50 Hz |

VNT’s Industrial Coffee Roaster Specification

Explore VNT’s Industrial Coffee Roasting System

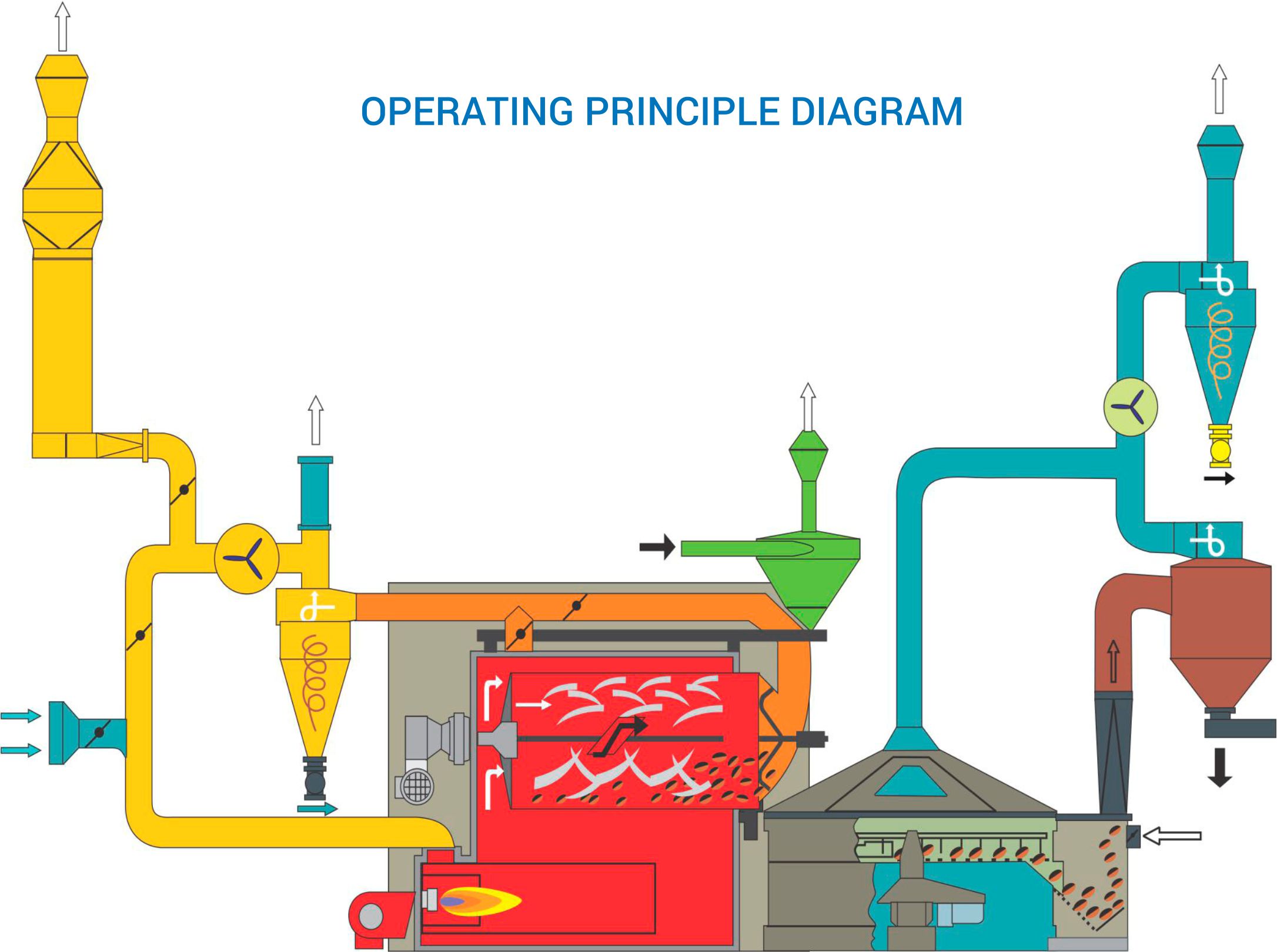

What are the key components of an industrial coffee roaster?

- Drum or Roasting Chamber: This is the main component where the roasting takes place. It is a horizontal, rotating drum made of steel or cast iron that can withstand high temperatures. The drum is often perforated to allow airflow and chaff removal.

- Feed Hopper: This is the loading mechanism that introduces the green coffee beans into the roasting drum. It controls the feed rate and ensures a consistent flow of beans.

- Burners or Heat Source: Industrial roasters use powerful burners or heat sources, typically fueled by natural gas, propane, or sometimes electricity, to generate the high temperatures required for roasting.

- Air System: An air system, including fans and ducting, is essential for circulating hot air through the roasting drum and removing smoke and chaff from the roasting chamber.

- Cyclone or Chaff Collector: This component separates the chaff (dried skin) from the roasted beans, ensuring a clean final product.

- Cooling Tray or Cooler: After roasting, the hot beans are discharged onto a cooling tray or into a separate cooler, where they are rapidly cooled with air to stop the roasting process.

- Controls and Automation: Modern industrial roasters are equipped with advanced controls and automation systems, allowing precise monitoring and adjustment of temperature, airflow, drum rotation speed, and other roasting parameters.

- Exhaust System: An efficient exhaust system is necessary to vent the smoke and other byproducts of the roasting process safely.

- Destoning and Sorting Mechanisms: These components help remove any remaining debris or defective beans from the roasted batch, ensuring consistent quality.

- Packaging or Bulk Storage: Depending on the setup, the roaster may have integrated packaging equipment or bulk storage containers for the roasted beans.

How does an industrial roaster works?

The journey begins by loading green, unroasted coffee beans into the roasting drum. As the drum rotates, the beans are gradually heated, undergoing three distinct stages: drying, browning, and development.

During the drying stage, moisture is removed from the beans, preparing them for the browning stage, where the Maillard reaction occurs, giving the beans their characteristic brown color and rich aroma.

Finally, in the development stage, the beans are exposed to higher temperatures, caramelizing the sugars and developing the desired flavor profile.

1. Feeding the Beans:

The first step in the industrial roasting process is introducing the raw, green coffee beans into the roaster. This is typically done through a hopper or feed mechanism that carefully measures and delivers the beans into the roasting chamber.

2.The Roasting Chamber

At the heart of every industrial coffee roaster lies the roasting chamber – a cylindrical, rotating drum or fluid bed roaster. This chamber is heated to precise temperatures, typically ranging from 370°F to 540°F (188°C to 282°C), using powerful heat sources such as natural gas, propane, or electricity.

3. Agitation and Airflow: Ensuring Even Roasting

As the beans tumble inside the roasting chamber, they are continuously agitated by paddles, fins, or other mechanisms. This constant motion ensures that every bean receives even heat exposure, preventing scorching and promoting consistent roasting. Additionally, a stream of hot air is circulated through the chamber, providing the necessary heat for the roasting process while simultaneously removing chaff (the dried skin that falls off the beans) and smoke.

4. The Cooling Phase: Preserving Perfection

Once the desired roast level is achieved, the freshly roasted beans are swiftly discharged from the roasting chamber into a cooling tray or cyclone cooler. Here, they are rapidly cooled with air, halting the roasting process and preserving the perfect flavor and aroma profile.

Conclusion

Industrial coffee roasters are true marvels of engineering, combining precision temperature control, efficient airflow, and automated processes to deliver exceptional roasted coffee on a massive scale. From the initial feeding of green beans to the final packaging, each step is meticulously executed to ensure that every cup you savor is a testament to the art and science of industrial coffee roasting.