Coffee lovers, have you ever wondered about the journey your favorite brew takes before it reaches your cup? The path from coffee cherry to aromatic bean is a fascinating odyssey, filled with crucial steps that shape the flavor, aroma, and quality of your morning pick-me-up. In this comprehensive guide, we’ll dive deep into the coffee processing flow chart, unraveling the intricate steps that transform raw coffee cherries into the exquisite beans we all know and love. Whether you’re a casual sipper or a budding barista, understanding this process will deepen your appreciation for every sip and might just make you the coffee connoisseur among your friends. So, grab your favorite mug, and let’s embark on this flavorful journey together!

Coffee Processing Flow Chart

Coffee Processing Flow Chart

Download Coffee Processing Flow Chart PDF

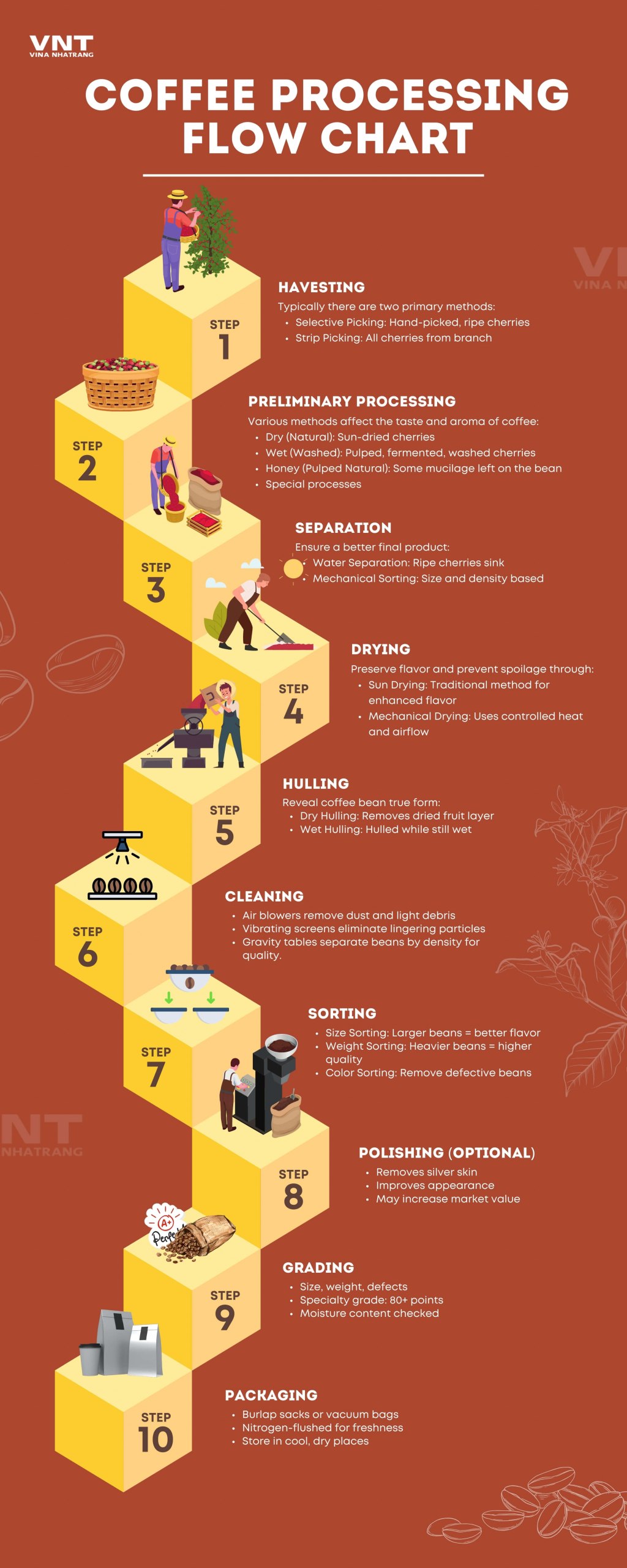

Steps of Coffee Processing

Harvesting: The First Step in Coffee Excellence

The coffee processing flow chart begins with harvesting, a critical stage that sets the foundation for quality. There are two primary methods:

- Selective Picking: Think of this as the VIP treatment for coffee cherries. Only the ripest, most perfect cherries are handpicked. This labor-intensive method ensures that each bean has reached its peak flavor potential.

💡 Fun fact

It takes about 2,000 hand-picked coffee cherries to produce just one pound of roasted coffee!

- Strip Picking: Imagine a quick sweep of the coffee branch, collecting all cherries regardless of ripeness. It’s faster and more efficient, especially for larger plantations. However, the resulting mix of ripe and unripe cherries can lead to inconsistent flavor profiles in the final product.

Coffee Harvesting Methods: Selective Picking and Strip Picking

💡 Did you know?

The harvest season varies globally. While most regions have one annual harvest, some lucky areas, like Colombia, enjoy two harvests thanks to their unique climate patterns. This geographical diversity in harvesting seasons contributes to the year-round availability of fresh coffee beans in the global market.

The choice between selective picking and strip picking, as well as the timing of the harvest, can significantly influence the flavor profile and quality of the final coffee product. As we move further along the coffee processing flow chart, these initial decisions made during harvesting continue to shape the journey of the coffee bean, ultimately affecting the cup of coffee that ends up in your hands.

Preliminary Processing: Where Flavor Begins to Develop

Once the ripe coffee cherries have been harvested, they enter the crucial stage of preliminary processing. This phase is where the magic truly begins, setting the foundation for the coffee’s ultimate flavor profile. The method chosen at this stage can dramatically influence the taste, aroma, and body of the final brew in your cup.

Dry Processing (Natural)

Imagine vast patios or raised beds under the warm sun, covered with layers of ruby-red coffee cherries. This is the scene of dry processing, also known as the natural method. Here, the entire coffee cherry is left intact and allowed to dry in the sun, typically for several weeks. Workers diligently rake and turn the cherries regularly to ensure even drying and prevent unwanted fermentation.

Know More:- industrial coffee grinder | commercial coffee roaster machine | wood chip burner

This method, popular in regions with low humidity like Ethiopia and Brazil, imparts a unique flavor profile to the beans. As the cherry dries around the bean, it imparts some of its sweetness and fruit flavors. The result? A coffee with a heavier body, lower acidity, and pronounced fruity notes. It’s not uncommon to detect hints of blueberry, strawberry, or even tropical fruits in naturally processed coffees.

However, this method requires precise control. Too much moisture can lead to unwanted fermentation or even mold, while overly dry conditions can result in brittle, flavorless beans.

| Description | Process | Flavor impact | Popular in |

|

|

|

|

Drying process is popular in regions with low humidity

Wet Processing (Washed)

In contrast to the natural method, wet processing is akin to giving the coffee beans a spa treatment. This method begins with the immediate removal of the cherry’s outer skin and pulp, leaving only the bean encased in its parchment layer and a sticky mucilage.

The beans then undergo a fermentation process, either in water tanks or through mechanical scrubbing, to remove the mucilage. After fermentation, the beans are thoroughly washed and then dried, either under the sun or in mechanical dryers.

Wet processing, favored in regions like Colombia and Costa Rica, produces a distinctly different cup profile. These coffees typically showcase a cleaner, brighter taste with higher acidity and more distinct flavor notes. You might experience citrusy overtones, floral aromas, or a crisp, tea-like body in washed coffees.

| Description | Process | Flavor impact | Popular in |

|

|

|

|

Wet process produces a brighter cup with higher acidity.

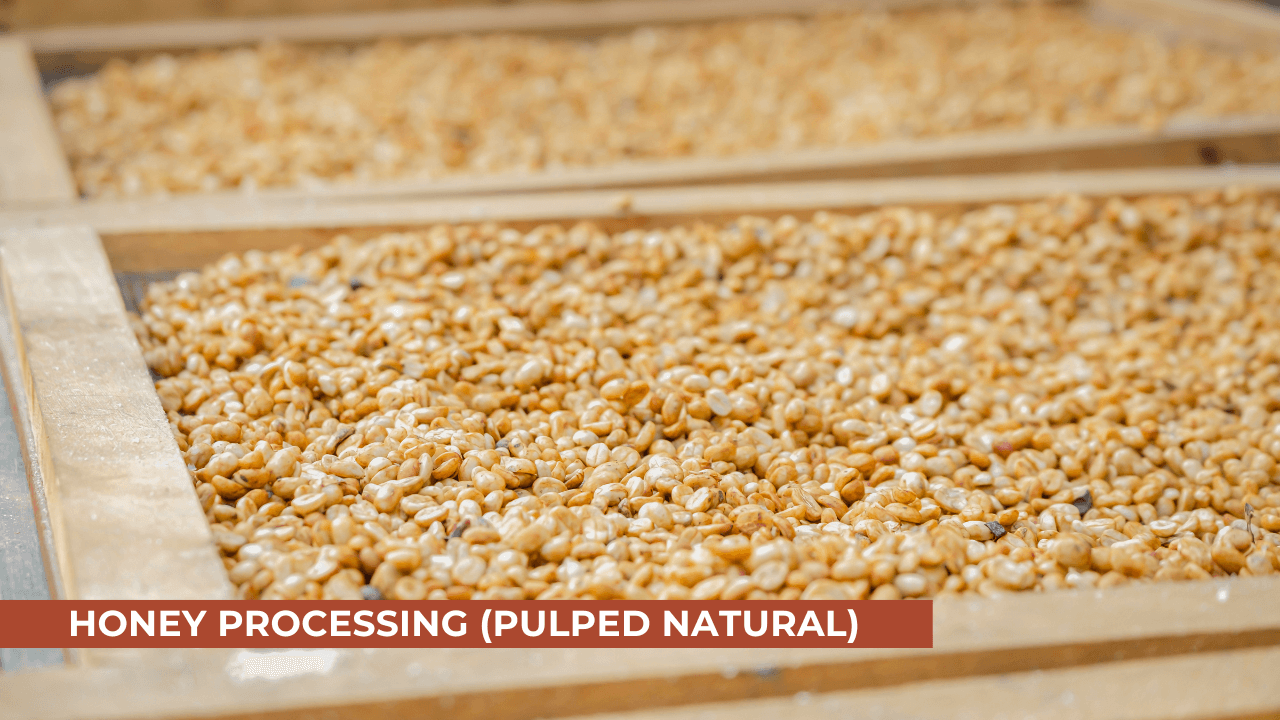

Honey Processing (Pulped Natural)

Sitting between the natural and washed methods is honey processing, a technique gaining popularity in the specialty coffee world. Despite its name, no honey is used in this process. Instead, it refers to the sticky, honey-like mucilage left on the bean during drying.

In honey processing, the cherry’s skin and pulp are removed, but varying amounts of mucilage are left on the bean as it dries. The amount of mucilage left on determines whether it’s a white, yellow, red, or black honey process, with each yielding slightly different flavor profiles.

This method offers a beautiful balance between the heavy sweetness of natural processing and the clean acidity of washed coffees. Honey-processed coffees often boast a smooth, sweet cup with moderate acidity and a syrupy body.

| Description | Process | Flavor impact | Popular in |

|

|

|

|

Honey process offers a balance between body and acidity

Special Processes

For the adventurous coffee enthusiasts, there are even more experimental processing methods emerging. These special processes are at the cutting edge of coffee production, constantly pushing the boundaries of what’s possible in terms of flavor development.

- Anaerobic Fermentation:

| Description | Process | Flavor impact | Ideal for |

|

|

|

|

- Carbonic Maceration: Similar to anaerobic fermentation but with added carbon dioxide, enhancing specific flavor compounds. Here, whole coffee cherries are fermented in a carbon dioxide-rich environment, enhancing the development of specific flavor compounds. The result can be a coffee with heightened fruitiness and a particularly clean, bright profile.

| Description | Process | Flavor impact | Ideal for |

|

|

|

|

Separation: Ensuring Only the Best Beans Make the Cut

As we journey further along the coffee processing flow chart, we arrive at a critical juncture: separation. Think of this stage as the coffee world’s version of “The Voice” auditions, where only the most promising contestants make it through. In this case, our contestants are coffee cherries and beans, each vying for a spot in your future cup of joe.

Water Separation

For wet-processed coffees, water separation is the first line of defense against subpar beans. Picture a grand pool party for coffee cherries, but with a twist – this party determines their fate. As the cherries are dumped into water-filled tanks, a fascinating phenomenon occurs. The ripe, high-quality cherries sink to the bottom like Olympic swimmers touching the wall, while the undesirables – unripe, overripe, or damaged cherries – float to the surface like beachgoers on pool floats.

This simple yet effective method relies on the principle that ripe cherries are denser due to their higher sugar content. It’s nature’s way of signaling, “These are the ones you want!” Farmers and processors can then easily skim off the floaters, ensuring that only the cream of the crop (or in this case, the sinkers of the tank) move on to the next stage of processing.

💡 Water Separation:

- Picture a coffee cherry swimming pool where the best ones sink to the bottom.

- Used in: Wet processing

- How it works: Ripe cherries sink, while defective ones float to the surface.

Mechanical Sorting

For our dry-processed coffee friends, mechanical sorting steps in as the guardian of quality. Imagine a complex, coffee-themed obstacle course designed by engineers with a passion for precision. These mechanical sorters are the unsung heroes of the coffee world, tirelessly working to separate cherries based on size and density.

Using a combination of screens, air jets, and vibrating platforms, these machines can detect the slightest differences between coffee cherries. Smaller, underdeveloped cherries are sifted out, while damaged or overly light cherries are whisked away by carefully calibrated air streams. It’s like a highly choreographed dance, with each movement designed to elevate the overall quality of the batch.

💡 Mechanical Sorting:

- Imagine a high-tech obstacle course for coffee cherries.

- Used in: Dry processing

- How it works: Machines sort cherries based on size and density.

Coffee beans sorted by machine on street in Vietnam

The Importance of Separation

You might be wondering, “Why go through all this trouble? Isn’t a coffee cherry just a coffee cherry?” Oh, dear coffee lover, if only it were that simple! The separation stage is crucial for several reasons:

- Quality Control: By removing defective cherries early in the process, we dramatically improve the overall quality of the final product. It’s the coffee equivalent of weeding out bad apples before they spoil the bunch.

- Consistency: Proper separation ensures that the beans moving forward in the process are uniform in size and quality. This consistency is key for even roasting later on, which in turn leads to a more balanced cup of coffee.

- Efficiency: Removing subpar cherries at this stage saves time and resources in the later stages of processing. It’s much easier to deal with these outliers now than to try and compensate for their effects down the line.

- Flavor Preservation: Defective cherries can introduce off-flavors into the mix. By removing them, we’re protecting the integrity of the good beans and preserving the unique flavor profiles that make each coffee special.

The next time you savor a particularly good cup of coffee, spare a thought for the unsung heroes of the separation stage. Their meticulous work in sorting and selecting only the best cherries plays a crucial role in ensuring that each sip is as close to perfection as possible. After all, in the world of specialty coffee, excellence isn’t just encouraged – it’s quite literally separated from the rest.

Drying: The Art of Precision Moisture Control

Welcome to the drying stage, where coffee beans learn the delicate art of balance. Think of this as a spa retreat for our coffee beans, but instead of relaxation, they’re on a strict moisture-loss regimen.

Sun Drying

Picture vast fields of coffee beans basking under the warm sun, like sunbathers on a tropical beach. This traditional method is coffee’s way of getting an all-natural tan. Workers meticulously spread the beans on large patios or raised beds, regularly raking them to ensure even exposure. It’s like a synchronized sunbathing routine, but for coffee!

While sun drying can enhance flavor complexity, it’s not without its challenges. It’s weather-dependent and time-consuming – imagine planning a beach day only to have it ruined by unexpected rain. That’s the daily struggle of sun-drying coffee.

💡 Sun Drying:

- Pros: Traditional method that can enhance flavor complexity.

- Cons: Weather-dependent and time-consuming.

Arabica coffee beans drying in the sun

Mechanical Drying

For those beans that prefer a more controlled environment, mechanical dryers offer a consistent, weather-proof alternative. These machines are like giant hair dryers for coffee, providing carefully regulated heat and airflow. It’s faster and more predictable than sun drying, making it ideal for regions where Mother Nature can’t be trusted to cooperate.

The goal? Achieve that perfect 10-12% moisture content. Too high, and you’re inviting mold to the party. Too low, and you’ve turned your beans into flavor-less pebbles. It’s a goldilocks situation – everything needs to be just right.

💡 Mechanical Drying:

- Pros: Consistent results and faster drying times.

- Ideal for: Regions with unpredictable weather or high humidity.

- Pro tip: The magic moisture content is between 10-12%. Too high, and you risk mold; too low, and you lose flavor complexity.

Hulling: Revealing the Hidden Gem

Hulling is where coffee beans shed their outer layers, revealing their true selves. It’s like a big reveal in a makeover show, but for coffee!

Dry Hulling

The Coffee Strip Tease For our sun-bathing, dry-processed beans, hulling removes that dried fruit layer, finally revealing the bean inside. It’s a bit like unwrapping a present, if the present were delicious coffee and the wrapping paper was made of dried fruit.

💡 Dry Hulling

- Used for: Dry-processed beans

- Process: Removes the dried fruit layer, revealing the bean inside.

Wet Hulling

Popular in Indonesia, wet hulling is like sending your coffee beans to a water park. The beans are hulled while still wet, contributing to the unique, often earthy and full-bodied flavors that Indonesian coffees are famous for. It’s a bit unconventional, but then again, so are some of the best things in life!

💡 Wet Hulling:

- Popular in: Indonesia

- Unique feature: Beans are hulled while still wet, contributing to the distinct flavor profiles of Indonesian coffees.

Coffee Huller Machine

Cleaning: The Coffee Bean Spa Treatment

After hulling, beans go through a thorough cleaning process:

- Air blowers: Whoosh away dust and light debris.

- Vibrating screens: Shake off any lingering particles.

- Gravity tables: Separate beans based on density for optimal quality.

Think of this step as the coffee equivalent of a high-end detox retreat – only the purest beans make it through!

Sorting: The Coffee Olympics

Welcome to the sorting stage, where coffee beans compete for gold medals in quality. It’s like the Olympics, but every participant is a coffee bean.

- Size Sorting: Beans are categorized by size using screens with different-sized holes. Larger beans typically jump higher in terms of flavor profile. It’s like the high jump, but instead of athletes, we have coffee beans trying to make it over the bar.

- Weight Sorting: Heavier beans are usually higher quality. Light, defective beans are removed. It’s the weightlifting portion of our Coffee Olympics, where only the strongest survive.

- Color Sorting: High-tech cameras identify and remove discolored or defective beans. It’s like a beauty pageant for coffee beans, where only the most visually appealing make it to the finals.

💡 Pro tip:

Next time you buy coffee, look for terms like “screen size” or “density sorted” – it’s a sign of quality focus in the processing.

Polishing: The Final Touchup

Polishing is the optional cosmetic surgery of the coffee world. It removes any remaining silver skin from the beans, giving them that extra shine. While it doesn’t significantly affect taste, it can make beans look like little coffee supermodels. Because sometimes, even coffee beans want to feel glamorous!

💡 Fun fact:

While polishing doesn’t significantly affect taste, it can make beans look like little coffee supermodels!

Grading: The Coffee Report Card

Grading is where coffee beans get their final score. It’s like a report card, but instead of math and science, we’re grading size, weight, and overall quality. Specialty coffee is graded on a scale from 1 to 100, with higher scores indicating superior quality. A score of 80+ is generally considered specialty grade coffee. Factors considered include defects, moisture content, and appearance.

💡 Did you know?

A score of 80+ is generally considered specialty grade coffee. It’s like getting an A+ on the coffee exam!

Packaging: The Final Frontier

We’ve reached the last stop on our coffee processing flow chart: packaging. This is where our coffee beans get tucked in for their journey to your cup.

Typically, beans are packed in burlap sacks or vacuum-sealed bags. Some get the VIP treatment with nitrogen-flushed bags for ultimate freshness. It’s like a space shuttle launch, but for coffee – we’re preparing these beans for their voyage to coffee lovers around the world!

Know More:- tower dryer | wood chip drying system | aroma recovery

Remember, proper storage is key. Cool, dry places are best to maintain quality. Think of it as tucking your coffee into a cozy bed, ensuring it stays fresh until it’s ready to wake up in your brewer.

And there you have it – from harvest to package, the entire journey of coffee processing. Next time you brew a cup, take a moment to appreciate the incredible odyssey each bean has undergone. It’s not just a beverage; it’s a globe-trotting adventure in every sip!

Coffee bags in warehouse

Have questions about coffee processing? Connect with out experts NOW.

Conclusion

As we’ve journeyed through the coffee processing flow chart, from the sun-kissed cherries to the carefully packaged beans, it’s clear that every step plays a crucial role in crafting the perfect cup. This intricate process, blending tradition with innovation, is what transforms a humble cherry into the complex, aromatic brew we cherish each morning. The next time you sip your coffee, take a moment to appreciate the craftsmanship behind each bean – it’s a testament to the dedication of farmers, processors, and roasters worldwide. Whether you prefer a fruity natural process or a clean, bright washed coffee, understanding this journey enhances not just your knowledge, but your entire coffee experience. So, coffee enthusiasts, which processing method intrigues you the most? Are you inspired to explore different types of coffees based on their processing? Share your thoughts and favorite coffee experiences in the comments below – let’s keep this flavorful conversation brewing!