COMMERCIAL COFFEE ROASTER MACHINE

- Fully automated PLC control system for consistent, repeatable roasts

- Advanced thermal sensors for precise temperature monitoring

- Specialized roasting analysis software for profile development

- Multiple capacity options: 1kg, 2.5kg, 5kg, 12kg, and 30kg

- Intuitive interface for complete control over roasting parameters

What is the Commercial Coffee Roaster Machine ?

A commercial coffee roaster machine is an advanced roasting machine designed for roasting coffee beans with precision and consistency. Using modern technology and techniques, it offers fully automatic control and adjustment of the roasting process, ensuring optimal flavor development for any type of coffee.

VNT's commercial coffee roaster machines are available in multiple capacities, ranging from 1kg to 30kg, combining cutting-edge technology with expert craftsmanship to deliver exceptional results for businesses of any size. It is perfect for artisan coffee shops, specialty roasters, and large-scale production facilities. Our roasters provide the precision and reliability needed to achieve outstanding results with every batch.

Technical Specifications

Commercial Coffee Roaster Machine's functions

- Primary Function: The commercial coffee roaster machine is specifically engineered for roasting green coffee beans into perfectly roasted coffee, ready for brewing. Through advanced technology and automated controls, it transforms raw beans into a finished product with exceptional consistency.

- Precision Timing: Each roasting cycle is precisely controlled, with roasting times ranging from 12 to 20 minutes. This optimal time range ensures proper flavor development while maintaining efficiency in production.

- Superior Quality Control: One of the roaster machine’s most significant achievements is its ability to maintain exceptional uniformity in roasting quality. It consistently delivers between 95-99% uniform coffee bean quality across each batch, ensuring professional-grade results for every roast.

- Advanced Connectivity: The roasting program features modern connectivity options, allowing seamless integration with various electronic devices. Users can monitor and control the roasting process through computers, smartphones and other compatible electronic devices

Commercial Coffee Roaster Machine's specifications

| Capacity | 3 – 4kg/hr, 200 – 1000gr/batch |

|---|---|

| Gas consumption | 4 – 5kg of gas/100kg of coffee beans |

| Electricity consumption | 850W |

| Power supply | 1 phase – 50Hz |

| Dimension (LxWxH) | 1420 x 600 x 1130 (mm) |

| Approx. weight | 190kg |

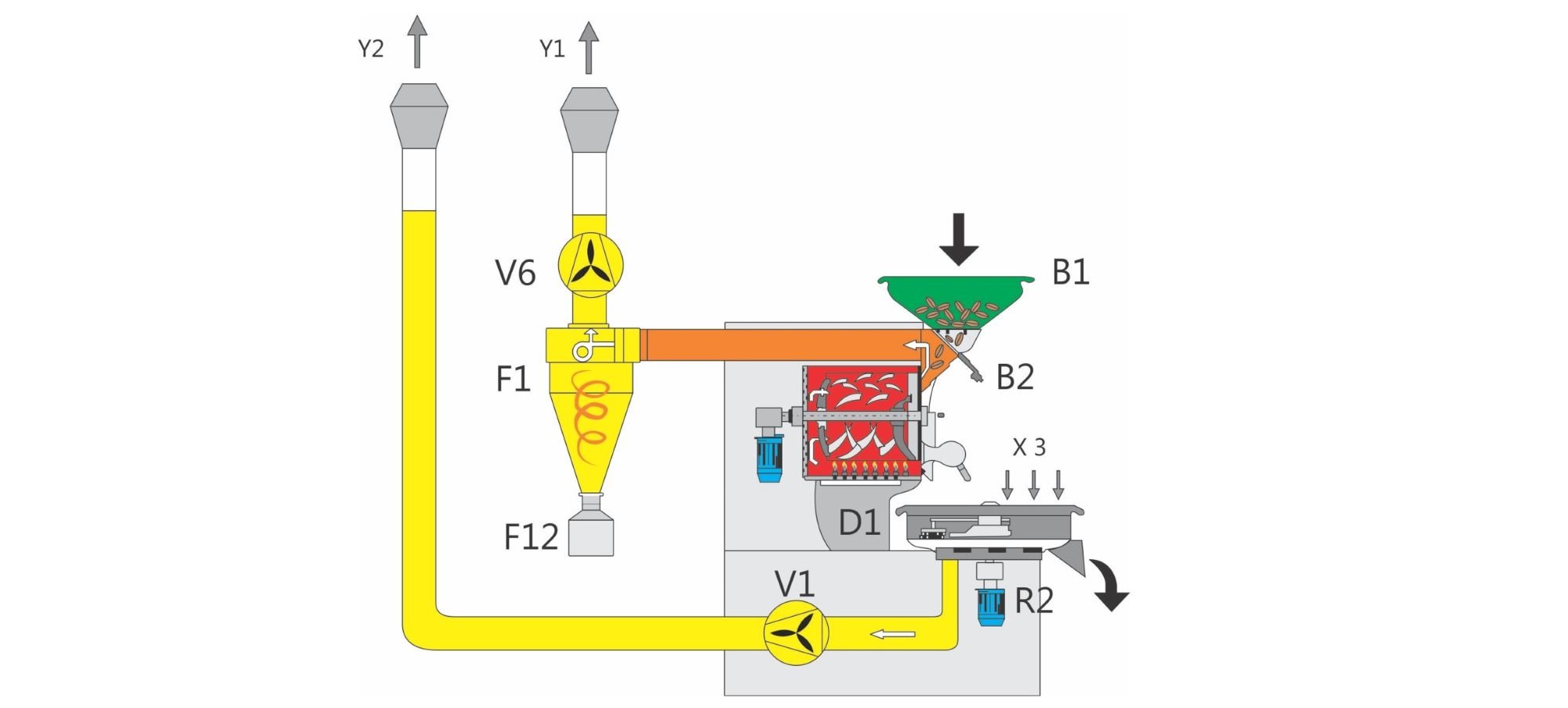

Commercial Coffee Roaster Machine's principles of operation

Commercial Coffee Roaster Machine's features of the control system

- Easy to control

- Manual control or Automatic Control via PLC monitor

- Connect to PC via Artisan software for saving roasting recipes

- HMI touch screen for easy interaction, while displaying roasting machine parameters, coffee beans temperature, hot air and temperature rises for 1 minute (BT, ET). Equipment status helps to control the roasting process to ensure the quality of coffee at the highest level

- The Phidgets 1048 hardware installed in the roaster is connected with 2 thermometers, for coffee bean temperature and air temperature. It analyzes and creates the basis for selecting and storing the most accurate profile. The optimal set-up process saves processing time, and above all, creates consistency in the quality of the finished products. Batches come out the same, every time.

Commercial Coffee Roaster Machine's functions of the roasting drum

- Air cushion

- Agitators in order to shine coffee beans, and restricts scorching the beans

- Ensures food safety standards

- Drum made from temperature resistant stainless steel

- Double rum jacket design to heat distribution consistent and to protect from a roasting defect happening

Commercial Coffee Roaster Machine's heating method

Rather than relying on traditional heating methods, our commercial coffee roasting roasting machines employ either an advanced infrared burner or a highly efficient blue flame burner. These state-of-the-art technologies ensure that the gas is burned completely, resulting in no smoke emissions.

This not only creates a cleaner, more pleasant work environment for our customers, but also maximizes the energy efficiency of the roasting process.

By eliminating wasteful combustion, VNT’s commercial coffee roaster machines deliver unparalleled performance and sustainability, making it the clear choice for discerning coffee roasting businesses.

Commercial Coffee Roaster Machine's cooling sieve & fan

- Efficient Cooling Mechanism: The roaster is equipped with a specialized cooling sieve and fan system that rapidly brings roasted beans to optimal temperature. This fast-cooling process takes just 3-5 minutes, ensuring the roasting process stops precisely when desired.

- Dust Collection System: A built-in cyclone dust collector effectively manages chaff and particulates generated during the roasting process. This advanced filtration system through cyclone technology is an integral part of the roaster’s design.

Commercial Coffee Roaster Machine's body of machine

- Body Structure: A commercial coffee roasting machine by VNT features robust construction, specifically designed for demands of commercial use. Built with heavy-duty reinforced steel, it provides the durability and strength needed for continuous operation in professional settings.

- Thermal Management: The machine body incorporates effective insulation throughout its design, specifically engineered to limit heat release to the external environment.

Commercial Coffee Roaster Machine's benefits

- One of the standout features is the ability to easily monitor the roasting process through the transparent panel. This allows our customers to make real-time adjustments to the roast profile, unlocking the unique flavors of each coffee bean.

- With precise temperature and time controls, they can tailor the roast to perfection, ensuring consistent, high-quality results batch after batch.

- We’ve engineered it to be a breeze to clean and maintain, minimizing downtime and maximizing productivity. And with our advanced infrared heating system, customers can expect up to 30-40% savings on gas consumption compared to traditional roasters, making it a truly cost-effective solution.

- VNT roaster has been designed with environmental sustainability in mind. By dramatically reducing harmful emissions like NOx and COx, we’re helping our customers operate in a more eco-friendly manner without sacrificing quality or efficiency.

Commercial Coffee Roaster Machine's customer services

At Vina Nha Trang, we go above and beyond to ensure our customers get the most out of their commercial coffee roaster machines. As part of our service, we offer:

- Complimentary roasting technology instructions, empowering even those new to coffee roasting to master our machines.

- Instructions to customers who do not have experience in commercial coffee roasting machines.

- We also provide comprehensive warranty coverage and on-site maintenance, dispatching our expert technicians directly to our customers’ locations world wide.

This level of personalized service is unmatched in the industry, demonstrating our dedication to the success of our customers. With Vina Nha Trang, our customers can focus on perfecting their craft, confident that we have their back every step of the way.

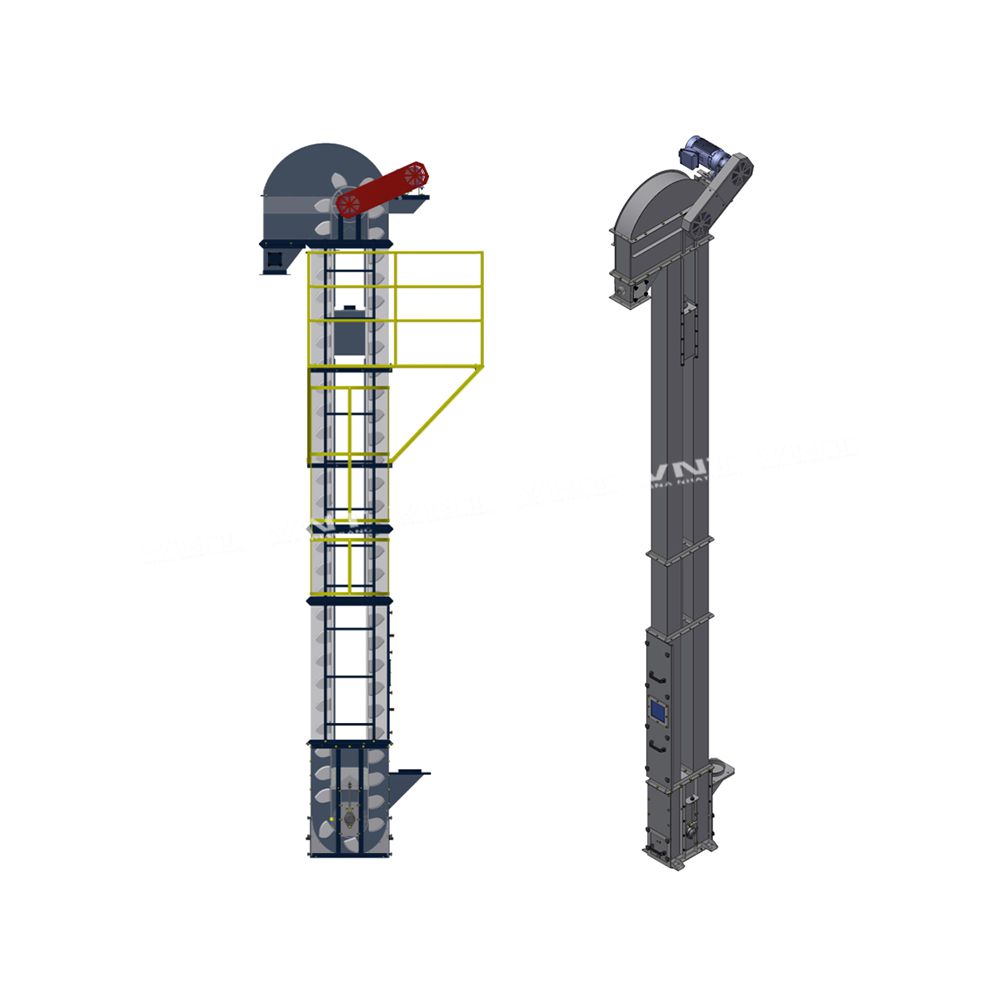

Commercial Coffee Roaster Machine's variants

Product's video

Frequently Asked Questions

What's kind of fuel that VNT coffee roaster use?

Commercial coffee roasting machines manufactures by VNT use gas as their main heating fuel.

What's kind of heating method is applied in a VNT commercial coffee roaster machine?

VNT’s commercial coffee roaster machines use indirect burning technology (hot air). The heat is transferred indirectly to the roasting drum (hot air transmission) so the heat is transferred to the coffee beans evenly, thereby optimizing the roasting batch quality.

How can I take a quick look of VNT's commercial coffee roaster machines?

VNT has more than 30 years experience in manufacturing equipment and systems for processing agricultural products such as coffee, pepper, cocoa … in Vietnam and over the world. Depending on your requirement of machine capacity, and your ability to travel to a factory’s location, we will be able to guide you to the most suitable locations for you to take a quick look of VNT’s coffee roaster machines. Please contact to our hotline (+84)-966-757-757 to get more information.

What is the warranty policy for VNT coffee roasting machine??

VNT provides free warranty service within 12 months from the date of delivery of the product for mechanical parts.

How can I get a quotation of the VNT's coffee roaster for sale?

Please contact to our hotline (+84)-966-757-757 for supporting. In addition, you can leave a message in the “Contact for Price” section below, we will get back to you within 24 hours.