COFFEE ROASTING & GRINDING SYSTEM

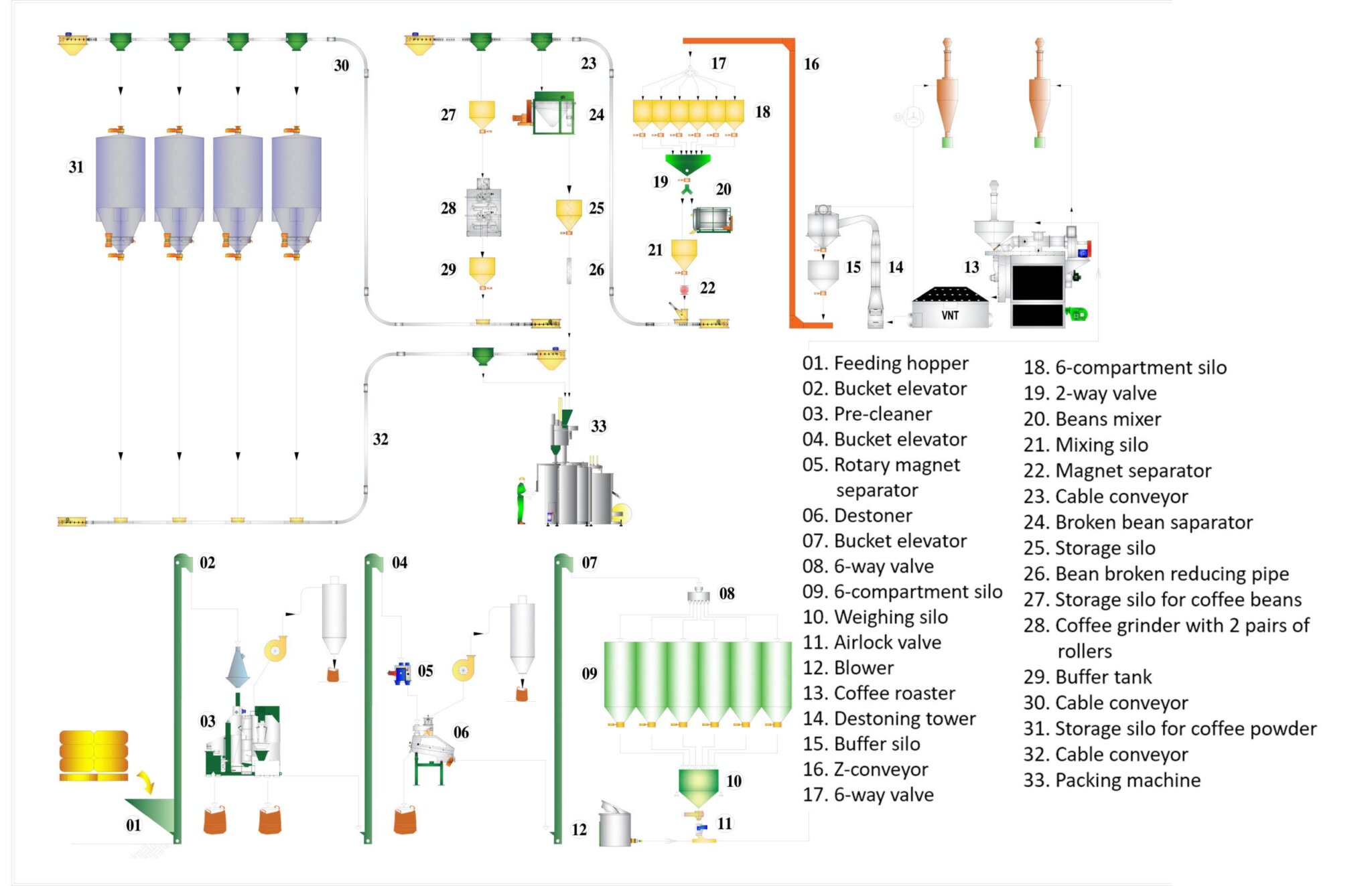

P&ID Diagram

Featured Projects

Main products:

Auxiliary Equipments:

Send Us An Inquiry

Complete control over products allows us to ensure our customers receive the best quality prices and service. We take great pride in everything that we do in our factory.

Industrial Coffee Roasting | Industrial Coffee Grinding

The coffee roasting and grinding process transforms raw coffee beans into a rich, aromatic powder ready for brewing. It begins with raw beans entering the industrial coffee roaster, where precise heat develops the beans’ flavor. After roasting, the beans are transported to an industrial coffee grinder—or industrial coffee mill—which grinds them into a uniform powder, essential for consistent brewing. Quality control, including destoning and magnetic separation, ensures each batch meets high standards. Finally, the coffee is stored and packaged, ready for distribution.

This process combines robust machinery with meticulous quality control, making it ideal for large-scale coffee production.

1. Initial Processing of Coffee Beans:

- Feeding Hopper (01): Raw coffee beans enter the system.

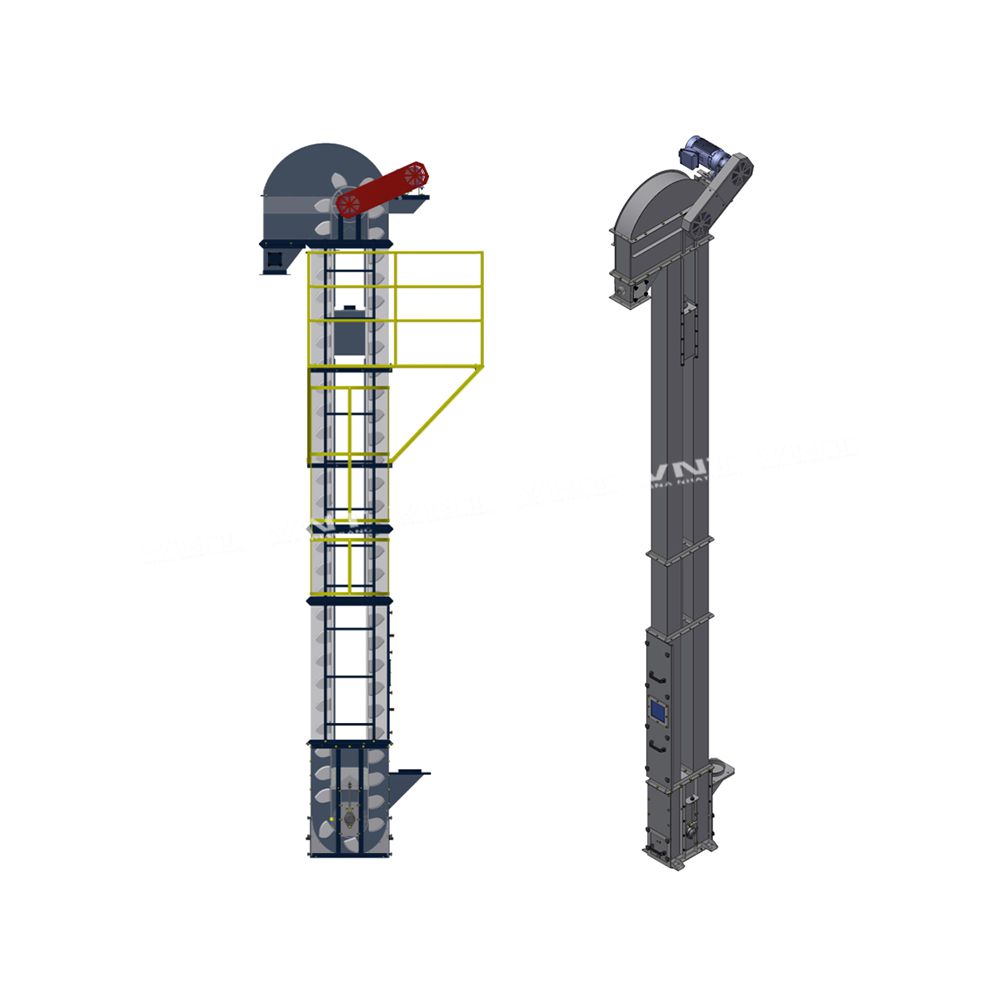

- Bucket Elevators (02, 04, 07): Transport beans through stages.

- Pre-Cleaner (03) and Rotary Magnet Separator (05): Remove impurities, including metals.

2. Industrial Cleaning and Sorting:

- Destoner (06): Separates stones from beans.

- 6-Compartment Silo (09, 18): Stores sorted, clean beans.

- Weighing Silo (10): Ensures consistent roasting batches.

3. Industrial Coffee Roaster Process:

- Industrial Coffee Roaster (13): Roasts beans for optimal flavor.

- Destoning Tower (14): Further purifies roasted beans.

- Buffer Silo (15): Holds beans before grinding.

4. Industrial Coffee Grinder (Grinding and Quality Control):

- Z-Conveyor (16): Moves roasted beans to grinding stages.

- Industrial Coffee Grinder with 2 Pairs of Rollers (28): Grinds beans uniformly.

- Broken Bean Separator (24): Removes defective beans for quality.

5. Final Mixing, Storage, and Packaging:

- Mixing Silo (21): Blends ground coffee for uniform quality.

- Storage Silo (23, 27) and Packing Machine (33): Prepares coffee for packaging.

This industrial coffee roasting and grinding system integrates high-performance machines to ensure consistency, quality, and efficiency across large-scale coffee production.