Factors like coffee roaster capacity, budget, roasting styles, and your unique coffee concept play a key role in selecting the coffee roaster equipment that best suits your roasting objectives. Whether you’re a small-scale artisanal roaster or a large-scale industrial operation, having the right tools and machinery is essential for achieving consistent, high-quality results and meeting customer demands. In this guide, we will guide you through the process of choosing the best coffee roaster equipment for your specific needs, whether you’re a commercial coffee roaster or a large-scale operation.

What is Coffee Roaster Equipment?

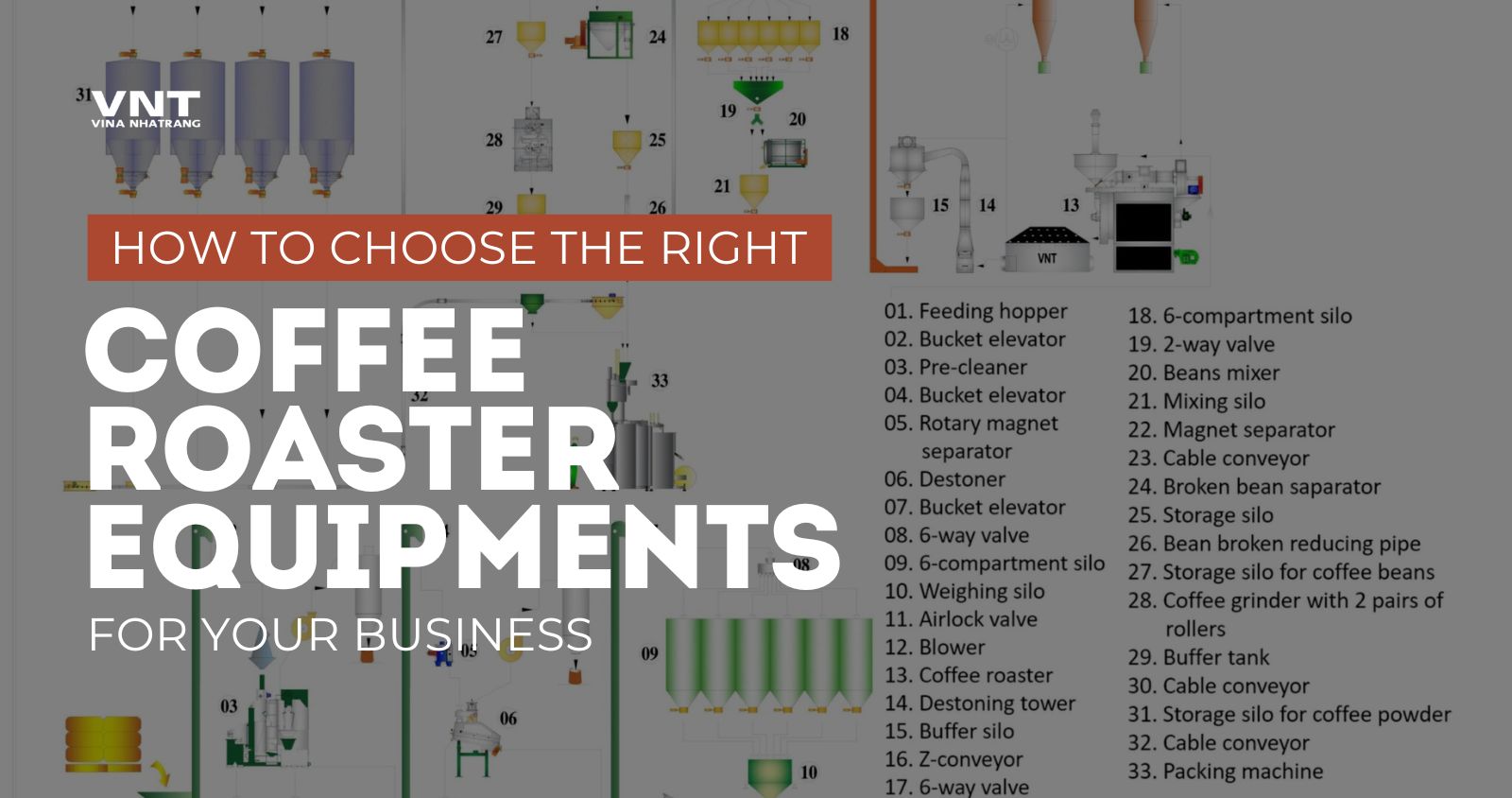

Coffee roaster equipment refers to the machinery and tools used in the process of roasting coffee beans. This equipment is specifically designed to roast green coffee beans and transform them into the roasted beans used to make coffee. These components include pre-cleaners, bucket elevators, rotary magnet separators, destoners, weighing silos, coffee roasters, and other auxiliary equipment. It can range from small, manually operated roasters used in commercial coffee businesses to large, automated systems used in industrial coffee production. Each piece of equipment plays a crucial role in different stages of the roasting process, from cleaning and sorting the green coffee beans to roasting them to perfection.

Explore our in-depth guide on Essential Coffee Roaster Equipment for your business

Factors to Consider when Choosing Coffee Roaster Equipment

Choosing the perfect coffee roaster for your business is about more than just a machine. It’s an investment in your success. By carefully considering these factors, you can ensure that you select the best equipment to meet your needs and achieve consistent, high-quality results.

Coffee Roaster Capacity

The first factor to consider when choosing coffee roaster equipment is your coffee roasting capacity. Assess your business needs and determine the volume of coffee you plan to roast on a daily or weekly basis. This will help you narrow down your options and ensure the equipment you choose can handle your production demands.

- Industrial Coffee Roasters: Designed for high-volume production, with batch sizes ranging from 60kg to 250kg. These roasters are typically found in large-scale coffee production facilities and are ideal for businesses with significant output requirements.

- Commercial Coffee Roasters: On the other hand, commercial coffee roasters are better suited for smaller operations, such as artisanal roasters, coffee shops, and medium-sized businesses. These roasters have a batch size ranging from 1kg to 30kg, offering greater flexibility and the ability to experiment with different roast profiles.

Space and Layout Requirements

Before investing in coffee roaster equipment, ensure that it fits comfortably within your available space and adheres to any local regulations or zoning requirements. Consider the roaster’s dimensions, ventilation needs, and any additional space required for auxiliary equipment or storage.

Automation and Control Features

Modern coffee roasters often come equipped with advanced control systems and automation features that ensure consistent results and efficient operations. Look for roasters with user-friendly interfaces, programmable roast profiles, and real-time monitoring capabilities. Automation can help streamline the roasting process, reduce human error, and improve overall efficiency.

Energy Efficiency and Environmental Impact

As businesses become increasingly conscious of their environmental footprint, it’s essential to consider the energy consumption and environmental impact of the roasting equipment. Look for energy-efficient roasters that minimize fuel consumption and emissions, not only to promote sustainability but also to reduce operational costs in the long run.

| Capacity | 36 – 48kg/hr, 6 – 12kg/batch |

|---|---|

| Gas consumption | 3 – 4kg of gas/100kg of coffee beans |

| Electricity consumption | 3.36 KWh |

| Power supply | 3 phase – 50Hz |

VNT’s Commercial Coffee Roaster is designed with power saving features.

Budget and Cost Considerations

Coffee roaster equipment can represent a significant investment, and it’s essential to carefully consider your budget when making a purchase. While high-quality equipment may come with a higher price tag, it often translates into better performance, longevity, and ultimately, a superior final product.

When budgeting for your coffee roaster equipment, take into account not only the cost of the roaster itself but also the associated components such as pre-cleaners, destoners, cooling trays, and packaging equipment. Additionally, factor in the ongoing expenses of maintenance and repairs to ensure the long-term sustainability of your operations.

Get consultations from our experts on how cost-effective incorporate VNT’s Coffee Roaster into your system

Maintenance and Service Support

Reliable maintenance and service support are essential for ensuring the longevity and optimal performance of your coffee roaster equipment. Choose equipment from reputable manufacturers that offer comprehensive support, including spare parts availability, technical assistance, and regular maintenance services. This can help minimize downtime and ensure your roasting operations run smoothly.

Essential Components of Coffee Roaster Equipment

Now that you have identified the key factors to consider, let’s explore different coffee roaster equipment options and their pros and cons:

Pre-cleaners

Before the roasting process can begin, green coffee beans must undergo a thorough cleaning process to remove any impurities, debris, or foreign objects that could compromise the final product’s flavor and quality. Pre-cleaners are the unsung heroes of the coffee roasting industry, serving as the first line of defense against potential contaminants.

These specialized machines come in various forms, including air cleaners, gravity separators, and spiral separators, each designed to effectively remove specific types of impurities from the bean batch. Investing in a high-quality pre-cleaner not only ensures a consistent supply of clean beans but also protects downstream equipment from potential damage caused by residual contaminants.

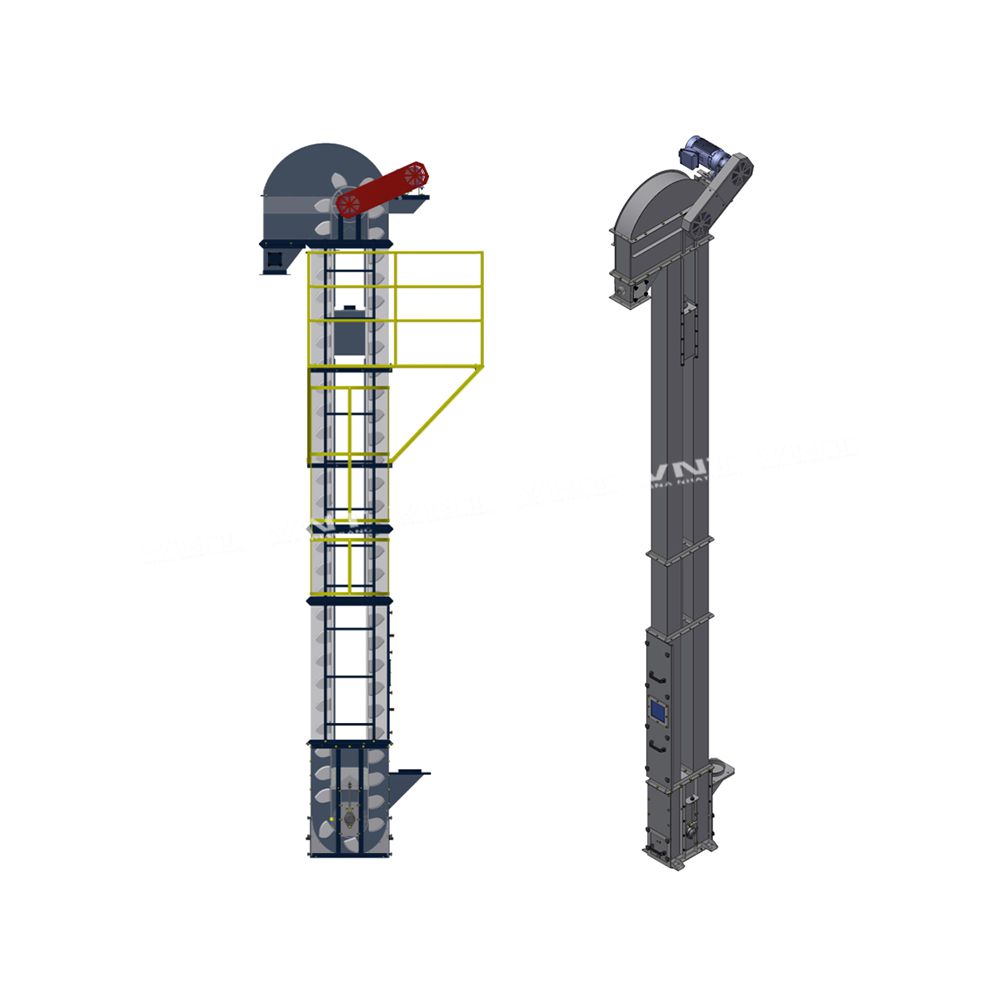

Bucket Elevators

Once the beans have been thoroughly cleaned, they need to be transported to the next stage of the roasting process – and that’s where bucket elevators come into play. These versatile conveyor systems are designed to move large quantities of beans smoothly and efficiently, minimizing the risk of spillage or cross-contamination.

Bucket elevators are not only essential for transporting beans between different processing stages but also play a crucial role in maintaining a continuous flow throughout the entire roasting operation. By seamlessly integrating with other equipment, bucket elevators help streamline the production process, improving overall efficiency and reducing downtime.

Rotary Magnet Separators

Even after the pre-cleaning stage, there is a possibility that some metal contaminants may still be present in the bean batch. This is where rotary magnet separators shine, using powerful magnetic forces to remove any residual metal fragments that could potentially damage downstream equipment or compromise the quality of the final product.

These separators are designed to work in tandem with other sorting and grading equipment, ensuring that only the highest-quality beans make it to the roasting stage. By eliminating the risk of metal contaminants, rotary magnet separators help protect the integrity of the roasting process and the longevity of your equipment.

Destoners

While pre-cleaners and magnet separators handle the removal of debris and metal contaminants, destoners play a vital role in separating dense materials, such as stones or small rocks, from the coffee beans. Even a single stone can cause significant damage to the roasting drums or negatively impact the roast profile, making destoners an indispensable part of any coffee roasting operation.

Destoners use a combination of advanced technologies, including air flow and vibration, to effectively separate dense materials from the lighter coffee beans. By ensuring that only the highest-quality beans make it to the roasting stage, destoners contribute to the consistent production of superior coffee products.

Weighing Silos

Accurate weighing is crucial for achieving consistent roasting results and delivering a product that meets the discerning tastes of your customers. Weighing silos play a vital role in this process, precisely measuring the weight of the green coffee beans before they enter the roasting stage.

These specialized silos not only ensure accurate weighing but also serve as temporary storage units, allowing for a smooth and continuous flow of beans throughout the roasting process. Many modern weighing silos are equipped with advanced control systems that enable seamless integration with other equipment, further enhancing the efficiency and automation of your roasting operations.

Coffee Roasters

At the core of every coffee roasting facility lies the roaster itself – a specialized piece of equipment that transforms simple green beans into the rich, aromatic coffee we know and love. The market offers a diverse range of roaster types, each with its unique characteristics and capabilities, catering to the specific needs of different roasting businesses.

Drum roasters, for instance, are a popular choice for their ability to produce consistent results and handle various batch sizes. Fluid bed roasters, on the other hand, prioritize energy efficiency and precise control over the roasting process. Tangential roasters offer a unique approach, using a combination of centrifugal force and hot air to achieve highly efficient and even roasting.

When selecting a coffee roaster, factors such as capacity, energy efficiency, and the level of control over roast profiling should be carefully considered. Many modern roasters come equipped with advanced roast profiling software, allowing for intricate adjustments and data analysis, ensuring consistent and repeatable flavor profiles.

Auxiliary Equipment

While the equipment mentioned above forms the backbone of any coffee roasting operation, several auxiliary components play crucial supporting roles. Cooling trays or bins are essential for rapidly cooling the roasted beans, preserving their flavor and preventing over-roasting. Chaff collectors help remove the chaff (outer skin) released during the roasting process, maintaining a clean and efficient working environment.

Packaging equipment is also a critical component, ensuring that the freshly roasted beans are sealed and protected from environmental factors that could compromise their quality and aroma.

Conclusion

Choosing the right coffee roaster equipment for your business is a decision that should not be taken lightly. By considering factors such as roasting capacity (kgs/hour), budget, and desired roast profiles (light, medium, dark), you can narrow down your options and make an informed choice. Whether you opt for a drum roaster, fluid bed roaster, or hybrid roaster, remember to prioritize quality, efficiency, and the ability to achieve your desired roast profiles. With the right equipment, you can elevate your coffee business and deliver exceptional coffee to your customers.