Introduction

Instant coffee has become a staple in many households worldwide, thanks to its convenience and ease of preparation. As a coffee business owner, it’s essential to understand the Instant Coffee Process Technologies that transform raw coffee beans into the soluble powder we know as instant coffee. In this blog post, we’ll dive into the fascinating journey of instant coffee production, from harvesting to packaging.

Discover the technologies used in VNT’s Instant Coffee Processing System.

Read more about The Manufacturing Process Of Instant Coffee

Harvesting and Selection of Coffee Beans

The first step in creating a quality cup of instant coffee begins with the selection of premium coffee beans. Instant coffee manufacturers typically use a blend of Arabica and Robusta beans sourced from renowned coffee-growing regions such as Latin America, Africa, and Southeast Asia. The beans are carefully handpicked to ensure only the ripest and healthiest ones make it to the next stage.

Roasting

Once the beans have been selected, they undergo the crucial roasting process. Roasting is an art form that involves carefully controlling temperature and time to develop the coffee’s unique flavor profile. Skilled roasters monitor the process closely, adjusting variables to achieve the desired roast level, ranging from light to dark. The roasting step is critical in determining the final taste and aroma of the instant coffee.

Grinding

After roasting, the beans are ground to a specific size that optimizes solubility in the instant coffee production process. The grind size plays a significant role in the extraction efficiency and the overall quality of the final product. A consistent and uniform grind ensures that the coffee particles dissolve easily when mixed with water, resulting in a smooth and flavorful cup of instant coffee.

Extraction

The ground coffee then undergoes a brewing process where hot water is used to extract the soluble coffee compounds. This step creates a concentrated coffee solution that is further processed to remove excess water content. The extraction process is carefully controlled to ensure that the desired flavor compounds are effectively extracted while minimizing the presence of bitter or undesirable elements.

Explore VNT’s Instant Coffee Extraction System, designed for efficient and high-quality extraction.

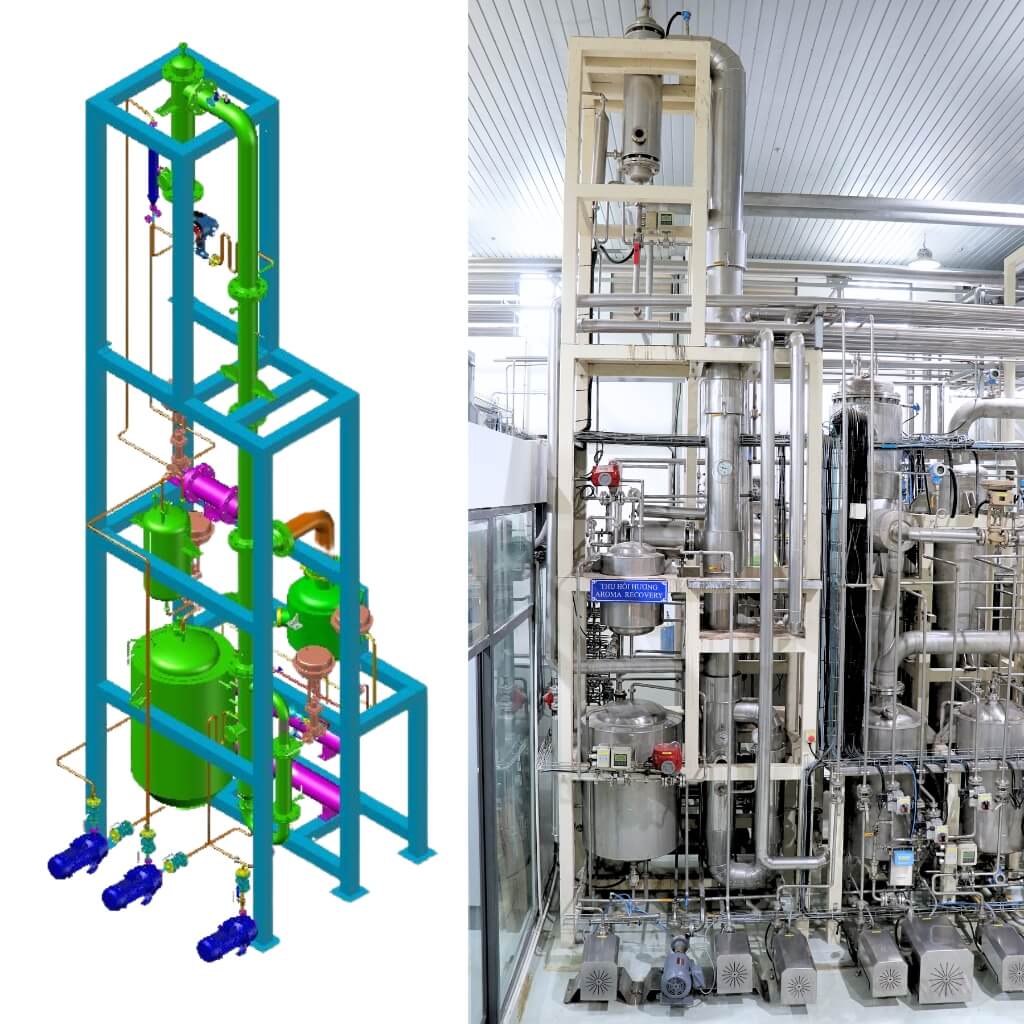

Evaporation

After extraction, the concentrated coffee solution undergoes an evaporation process to further reduce its water content. This step is crucial in creating a more concentrated and stable product that can be easily processed into instant coffee. The evaporation process typically involves heating the coffee solution under reduced pressure conditions, which lowers the boiling point of water and allows for more efficient removal of moisture. The resulting concentrated coffee extract is then ready for the next stages of instant coffee production.

Read more about Evaporation Technology

Enhance your instant coffee production with VNT’s Instant Coffee Evaporation System.

Dehydration Methods

There are two primary methods used to remove water from the concentrated coffee solution: freeze-drying and spray-drying.

Freeze-Drying

Freeze-drying is a gentle dehydration method that preserves the delicate flavors and aromas of the coffee. The coffee extract is first frozen and then slowly dried under vacuum conditions. This process allows the ice to sublimate directly into vapor, leaving behind a porous and easily soluble coffee powder. Freeze-drying is known for producing instant coffee with superior flavor retention, albeit at a higher production cost.

Spray-Drying

Spray-drying is a more cost-effective alternative to freeze-drying. In this method, the coffee extract is sprayed into a chamber filled with hot air, causing the water to rapidly evaporate. The resulting powder is fine and uniform in size. While spray-drying may not preserve the flavors as well as freeze-drying, it remains a popular choice for many instant coffee manufacturers due to its efficiency and lower cost.

Upgrade your spray-drying capabilities with VNT’s advanced Instant Coffee Spray Dryer.

Aromatization

During the manufacturing process, some of the aromatic compounds in the coffee may be lost. To compensate for this, instant coffee producers employ various techniques to recover and reincorporate these valuable aromatics. One common method involves capturing the volatile compounds during the roasting or extraction stages and later reintroducing them into the instant coffee powder. This aromatization step helps to enhance the overall flavor and aroma of the final product.

Elevate your instant coffee’s aroma profile with our Instant Coffee Aroma Recovery System

Agglomeration

Agglomeration is a process that involves combining the fine instant coffee particles into larger, more porous granules. This step enhances the solubility of the instant coffee and improves its physical properties, such as flowability and resistance to caking. Agglomerated instant coffee dissolves more readily in water, ensuring a consistent and enjoyable coffee experience for consumers.

Packaging

Proper packaging is crucial in maintaining the quality and freshness of instant coffee. The packaging materials used must provide an effective barrier against moisture, oxygen, and other environmental contaminants that can degrade the coffee’s flavor and aroma over time. Common packaging options include airtight glass jars, vacuum-sealed pouches, and nitrogen-flushed tins. Each packaging method has its advantages in terms of shelf life, convenience, and brand appeal.

Conclusion

The production of instant coffee involves a series of intricate processes that transform raw coffee beans into a convenient and flavorful beverage enjoyed by millions worldwide. From the careful selection of high-quality beans to the advanced dehydration and aromatization techniques, each step plays a vital role in creating the perfect cup of instant coffee. As a coffee business owner, understanding these Instant Coffee Process Technologies can help you appreciate the science behind your product and make informed decisions when sourcing and developing your instant coffee offerings. With ongoing technological advancements, the instant coffee industry continues to evolve, delivering an ever-improving coffee experience to consumers while maintaining the convenience and accessibility that make instant coffee so popular.

Contact our experts today to explore how our cutting-edge instant coffee processing solutions can benefit your business.