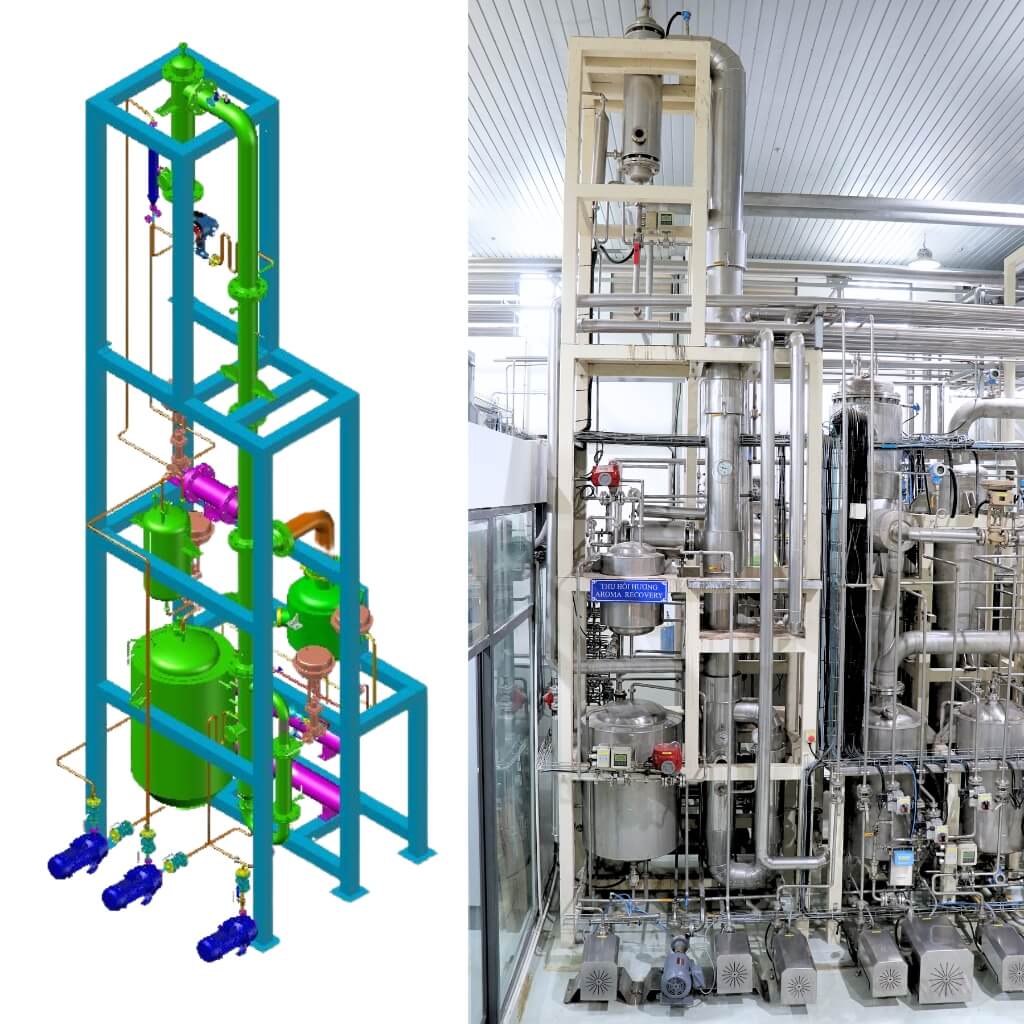

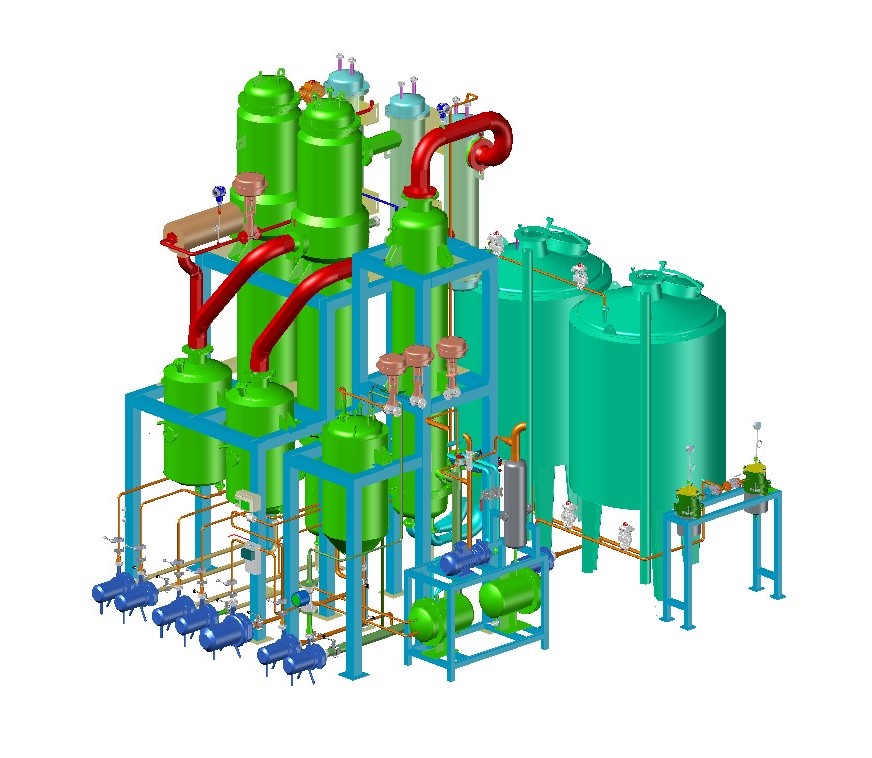

INSTANT COFFEE EVAPORATION SYSTEM

KEY BENEFITS:

- Utilizes falling-film evaporation technology under vacuum pressure.

- Minimizing heat damage and helping the extracted coffee solution maintain its quality and flavor components.

- Concentrates the extract to an appropriate level (likely for spray drying or freeze drying), facilitating a smooth and efficient drying process in the subsequent stages

- High Efficiency and Uptime

INTRODUCTION

What is the instant coffee evaporation system ?

The VNT's Instant Coffee Evaporation System plays a vital role in high-quality instant coffee production. This system utilizes advanced falling-film evaporation technology under vacuum pressure to deliver several key benefits:

- Preserved Coffee Flavor and Quality: Unlike traditional methods that can expose the coffee solution to high temperatures, the falling-film evaporator operates under vacuum pressure. This gentler processing technique helps safeguard the integrity of the coffee's flavor components, minimizing heat damage and ensuring the final instant coffee product retains its characteristic taste profile.

- Efficient Concentration for Streamlined Drying: The system efficiently concentrates the extracted coffee solution to an optimal level, perfectly suited for subsequent drying stages like spray drying or freeze drying. This optimized concentration contributes to a smoother and more efficient drying process, potentially reducing drying times and improving overall production efficiency. Furthermore, the system boasts an impressive continuous operation time of 20-22 hours, minimizing downtime for cleaning (CIP time: 2-3 hours) and maximizing production capacity.

OVERVIEW

Technical Specifications

Product's functions

- Falling-film evaporation technology is employed under vacuum pressure to help the extracted coffee solution maintain its quality, ensuring the preservation of flavor components even in high-temperature environments.

- The extract is concentrated to an appropriate level, facilitating a smooth drying process.

- Evaporation temperature >60°C

- Solids content achieves 55-56%

- Continuous operation time 20-22hours

- CIP time: 2-3 hours