PRE-CLEANER

- Effectively performs both pre-sieving and pre-cleaning for large quantities of grains and seeds, including coffee, beans, and pepper.

- Removes unwanted materials before further processing.

- Efficiently eliminates light impurities such as wire sewing sacks, leaves, and garbage, ensuring a cleaner product.

- Separate small grit and small batches of unwanted materials, offering a comprehensive cleaning solution.

What is the pre-cleaner ?

The VNT's Pre-Cleaner is a specialized machine designed for the initial cleaning and pre-processing stage of pepper. It utilizes a combination of vibration and fan suction to effectively clean large quantities of grains and seeds.

This machine offers several key benefits that contribute to improved efficiency and product quality:

- Enhanced Pre-Sieving and Pre-Cleaning: The Pre-Cleaner effectively performs both pre-sieving and pre-cleaning, removing unwanted materials before further processing. This initial cleaning step ensures a cleaner final product and protects downstream equipment from potential damage.

- Comprehensive Impurity Removal: It efficiently eliminates light impurities such as wire sewing sacks, leaves, and garbage, along with small grit and small batches of unwanted materials, providing a comprehensive cleaning solution.

Technical Specifications

Product's functions

- The machine can seperate above 90% impurities in pepper including: impurities smaller, larger and lighter than pepper (dust also)

- Machine can be separated: wire sewing sacks, leaves, garbage, other light impurities such as rice husk

- Machine can be separated: a small grit, small batch.

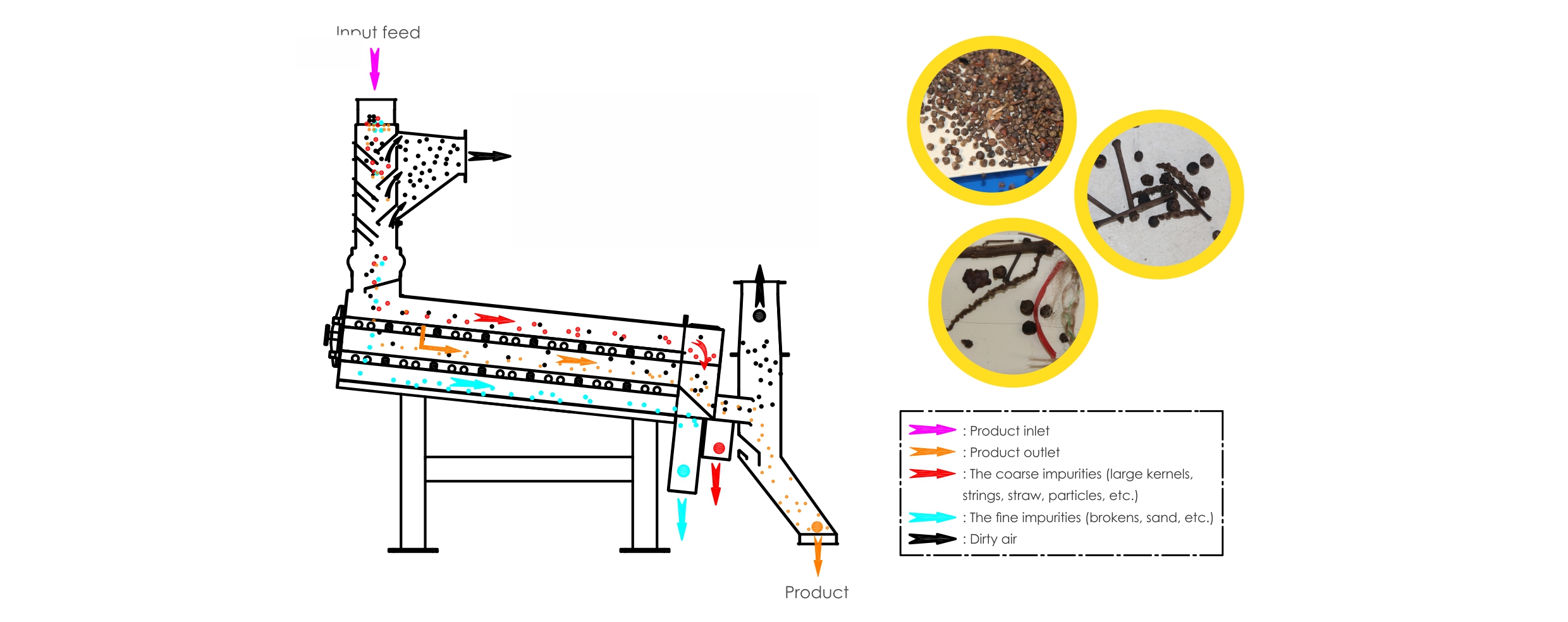

Product's principle of operation

- Principle of Aero dynamic

- Principle of Weight Separation

- Principle of Volume Separation

Product's specifications

| Model | Capacity (ton/hour) | Capacity (kW) | Dimension (LxWxH,mm) |

| MTC 1V – 3V – 6V – 8V | 1 – 8 | 0.55 x 2 | 2335 x 2110 x 2745 |

Product's product's working principle

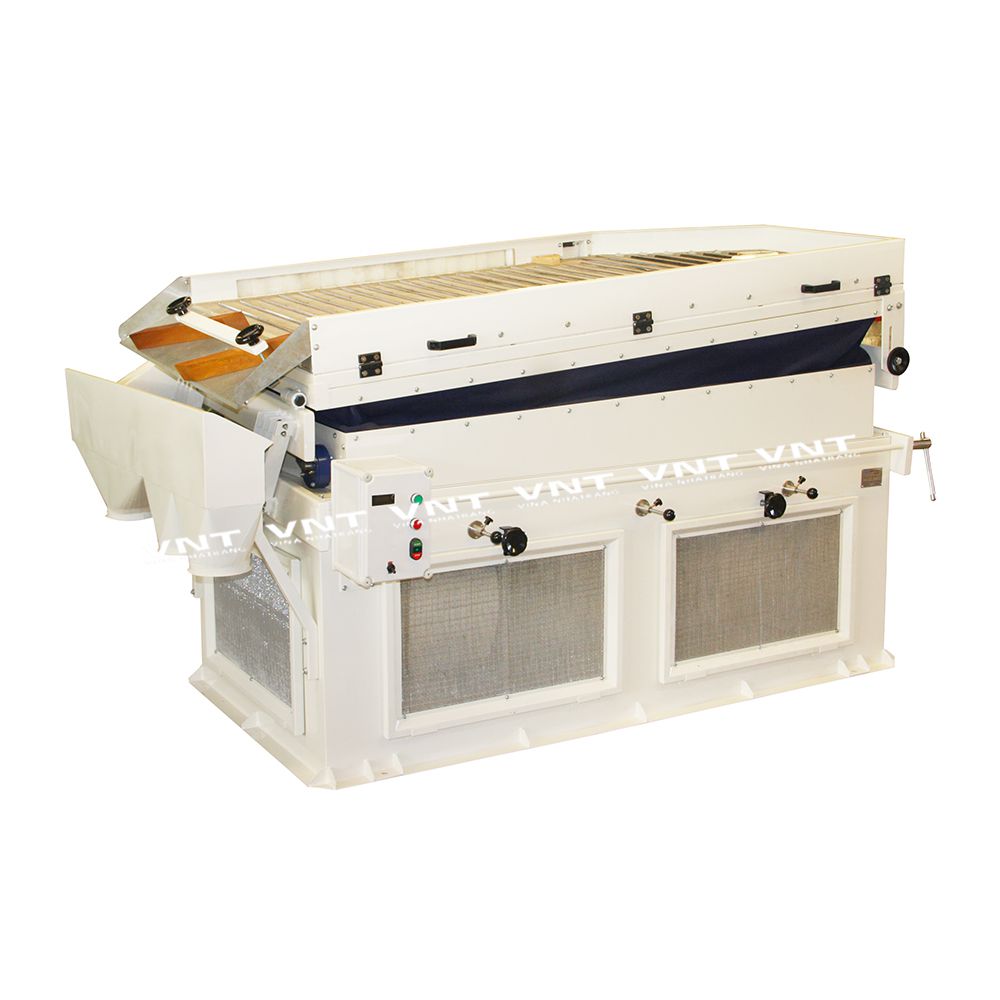

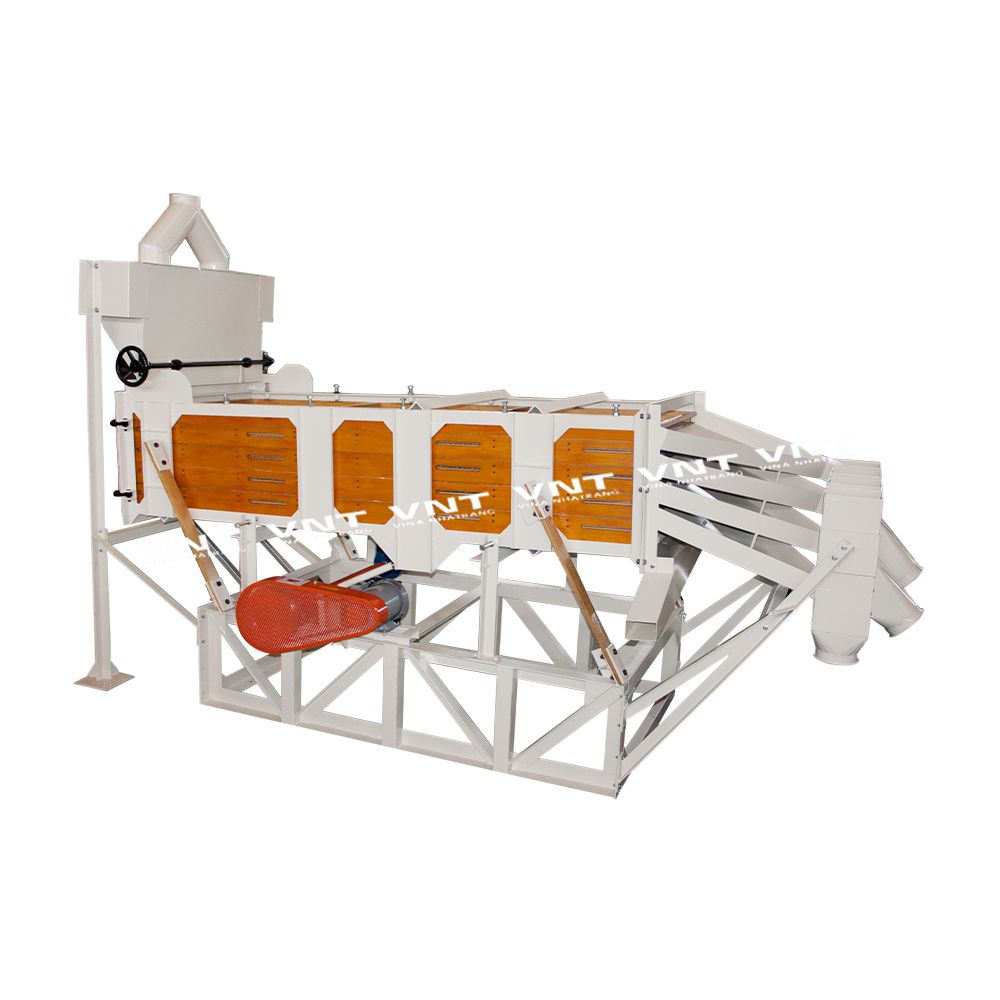

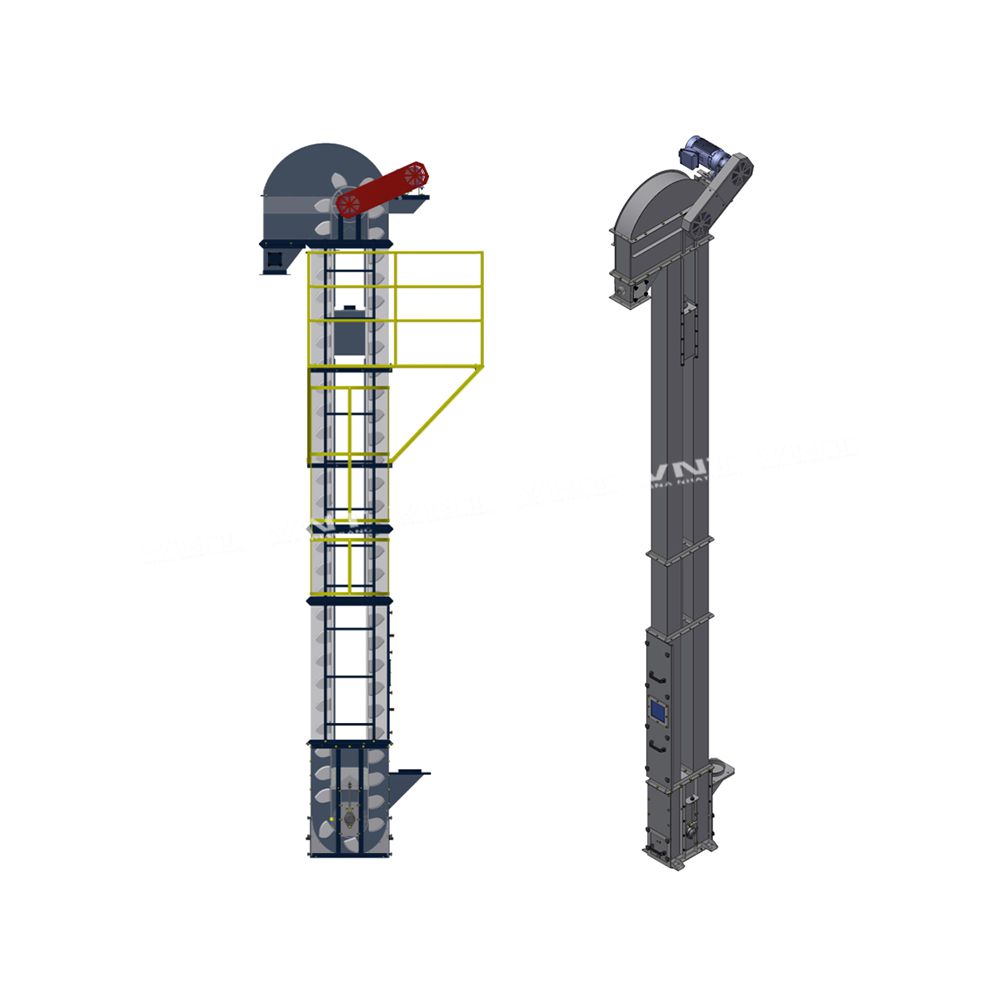

Product's pictures of machine

Product's advantages

- Modern technology

- High durability

- Easy to operate

- Electricity saving

- Improve processing efficiency for the whole system

- Minimize labor workforce in the processing line

Frequently Asked Questions

I want to visit VNT's sample system?

VNT has more than 30 years experience in manufacturing equipment and systems for processing agricultural products such as coffee, pepper, cocoa … in Vietnam and over the world. Depending on your requirement of machine capacity and factory’s location, we will give the most suitable advice as well as arrange a suitable place for you to visit. Please contact to our hotline 0966 757 757 to get more information.

I want to know about VNT warranty policy?

VNT provides free warranty service within 12 months from the date of delivery of the product for mechanical parts.

I want to know how to contact to VNT?

Please contact to our hotline 0966 757 757 for supporting. In addition, you can leave a message in the “Contact for price” section below, we will get back to you within 24 hours.