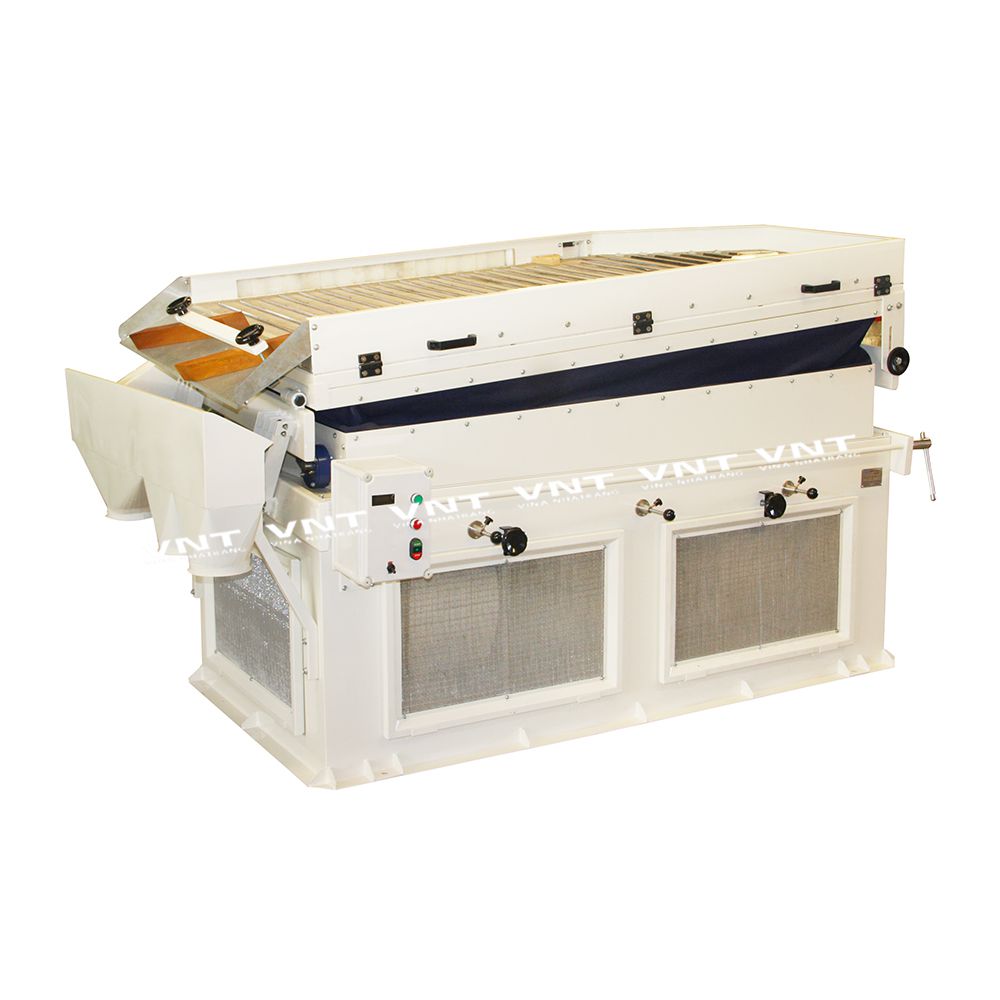

SIZE GRADER

- Effectively sorts grains based on size, ensuring consistent product quality and enabling targeted processing based on specific size requirements.

- Allows for adaptability to different needs and diverse grading requirements.

- Can handle a wide range of grain types and desired size specifications.

What is the size grader ?

The VNT's size grader plays a crucial role in post-cleaning processing stages for pepper. It comes into action after the materials have been meticulously cleaned and separated from impurities, rocks, and metal pieces. This machine is dedicated to achieving one key objective:

- Precise and Consistent Sizing: By effectively sorting grains based on their size, the size grader ensures consistent product quality and enables targeted processing. This allows you to categorize grains according to specific size requirements, catering to diverse needs and applications.

Beyond its core function, the size grader offers additional benefits:

- Flexible Adaptability: The adjustable mesh size allows the machine to adapt to various needs and handle a wide range of grain types with diverse size specifications.

- Streamlined Processing: By separating grains by size, the machine streamlines further processing steps, promoting efficiency and potentially minimizing waste.

Technical Specifications

Product's functions

- To classify size of agricultural grains such as pepper, coffee, beans, pepper etc. after the material has been separated from impurities, rocks and metal pieces

- Depending on the size need to be classified, the size of the mesh hole can be changed to fit its requirement

Product's specifications

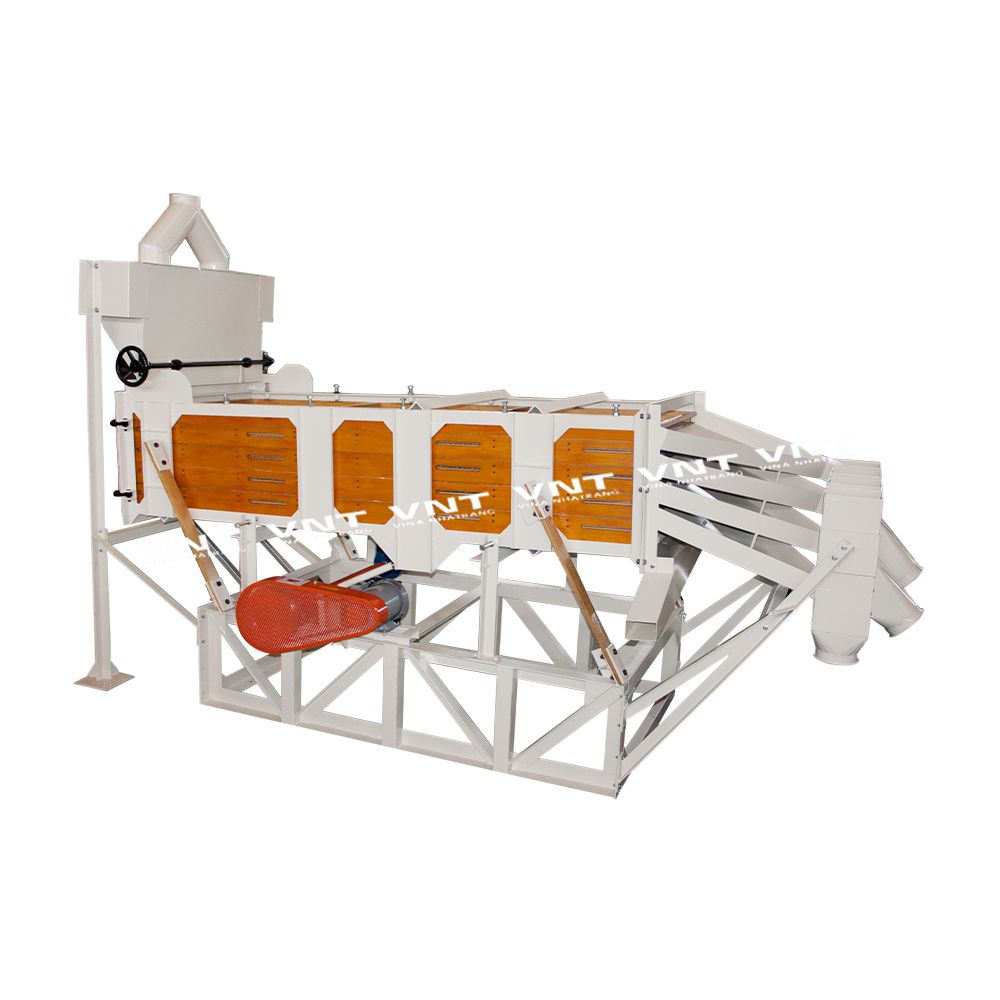

| Model | Capacity (ton/hour) | Power (HP) | Dimension (LxWxH,mm) |

| KT – 3 | 1 – 3 | 2 | 3375 x 950 x 2030 |

| KT – 6 | 4 – 6 | 3 | 6058 x 2400 x 3150 |

| KT – 12 | 10 – 12 | 4 | 8000 x 2600 x 4500 |

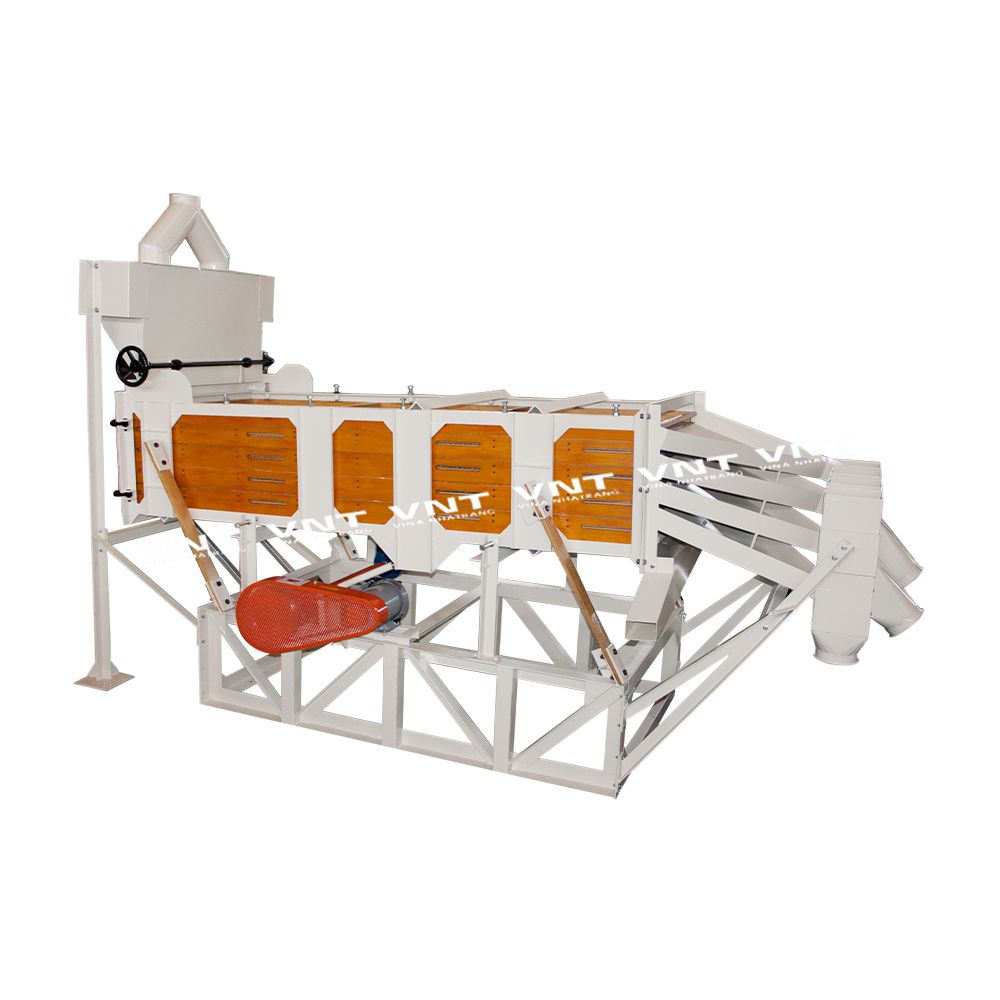

Product's advantages

- Modern technology

- High durability

- Easy to operate

- Electricity saving

- Improve processing efficiency for the whole system

- Minimize labor workforce in the processing line

Frequently Asked Questions

I want to know how to visit VNT's sample system?

VNT has more than 30 years experience in manufacturing equipment and systems for processing agricultural products such as coffee, pepper, cocoa … in Vietnam and over the world. Depending on your requirement of machine capacity and factory’s location, we will give the most suitable advice as well as arrange a suitable place for you to visit. Please contact to our hotline 0966 757 757 to get more information.

I want to know about VNT warranty policy?

VNT provides free warranty service within 12 months from the date of delivery of the product for mechanical parts.

I want to know how to contact to VNT?

Please contact to our hotline 0966 757 757 for supporting. In addition, you can leave a message in the “Contact for Price” section below, we will get back to you within 24 hours.