The instant coffee manufacturing process has revolutionized how millions of people worldwide enjoy their daily caffeine fix. From bustling offices to home kitchens, instant coffee provides convenience without compromising the rich coffee experience that consumers have come to expect.

Behind every jar of instant coffee lies a sophisticated transformation – one that turns carefully selected coffee beans into readily soluble granules. This intricate process combines time-honored coffee roasting techniques with modern food science innovations, ensuring that each cup delivers consistent flavor and aroma. Whether you rely on instant coffee for your morning routine or are curious about its production journey, understanding how it’s made reveals the remarkable engineering that makes your quick cup possible.

Introduction to the Instant Coffee Manufacturing Process

Instant coffee has a few other names you might have heard: soluble coffee and dried coffee extract. They all refer to the same thing – the convenient instant coffee powder or granules that dissolve in water – highlighting its physical properties and preparation process. The term “soluble coffee” refers to the ease with which it dissolves in water, and “dried coffee extract” emphasizes that the coffee has been concentrated and dried after extraction.

Fast forward to today, and advancements in technology have revolutionized the instant coffee manufacturing process. Modern methods, like freeze-drying, allow for the preservation of much more delicate coffee characteristics, resulting in instant coffees that can rival their freshly brewed counterparts. This evolution has transformed instant coffee from a wartime necessity to a convenient and flavorful option for today’s busy consumers.

The terms “soluble coffee” and “dried coffee extract” describe the coffee’s water solubility and the concentration and drying of the extracted coffee

Definitions and Composition

The instant coffee manufacturing process is held to strict standards in many countries, ensuring the product stays true to its coffee roots—no sneaky additives, except for some approved aroma oils. The International Standards Organization (ISO 3509–1989), first introduced back in 1970, defines instant coffee as “the dried water-soluble product, obtained exclusively from roasted coffee by physical methods using water as the only carrying agent.” Pretty straightforward, right?

- ISO Standard: This definition makes it crystal clear that no chemicals or solvents (other than water) are involved in making instant coffee. It’s all about preserving the coffee’s purity. The ISO standard represents a global agreement on what real instant coffee is, giving you peace of mind that no matter where you buy it, you’re getting the same quality product.

- European Economic Community (EEC) Directive: Now, the EEC Directive for coffee and chicory extracts, around since 1977 and updated in 1983, takes a slightly more flexible approach. It allows for insoluble oils from coffee and small traces of other substances, but—transparency is key—these must be clearly listed on the label. So, you’ll always know what’s in your cup!

Back in the day, instant coffee sometimes had added carbohydrates like corn syrup solids to improve its texture. The early versions were moisture magnets (hygroscopic), clumping together as soon as you opened the jar. But with modern technology, manufacturers figured out how to extract polysaccharides directly from roasted coffee at high temperatures—up to a scorching 175°C—eliminating the need for extra carbs. This led to the creation of 100% pure instant coffee, a major win for coffee lovers everywhere.

💡 Did you know? While brewed coffee typically provides around 21% soluble solids, instant coffee’s extraction process bumps that up to an impressive 40–55%, depending on how it’s roasted and blended. By pulling out extra soluble goodies like polysaccharides and caffeine, instant coffee delivers a richer, fuller cup that packs a flavorful punch!

Countries worldwide are pretty strict about what goes into instant coffee

Now, here’s a little industry secret: during the instant coffee manufacturing process, we end up with these leftover coffee grounds. We call them “spent grounds,” and they’re like the coffee world’s version of a puzzle – figuring out what to do with them can be tricky. But don’t worry, we’re getting creative! Some clever folks are turning these grounds into compost or even using them for energy production. Pretty cool, right?

Know More:- industrial coffee grinder | commercial coffee roaster machine | wood chip burner

But how exactly do we go from roasted beans to a ready-to-drink beverage in seconds?

Instant Coffee Manufacturing Processes

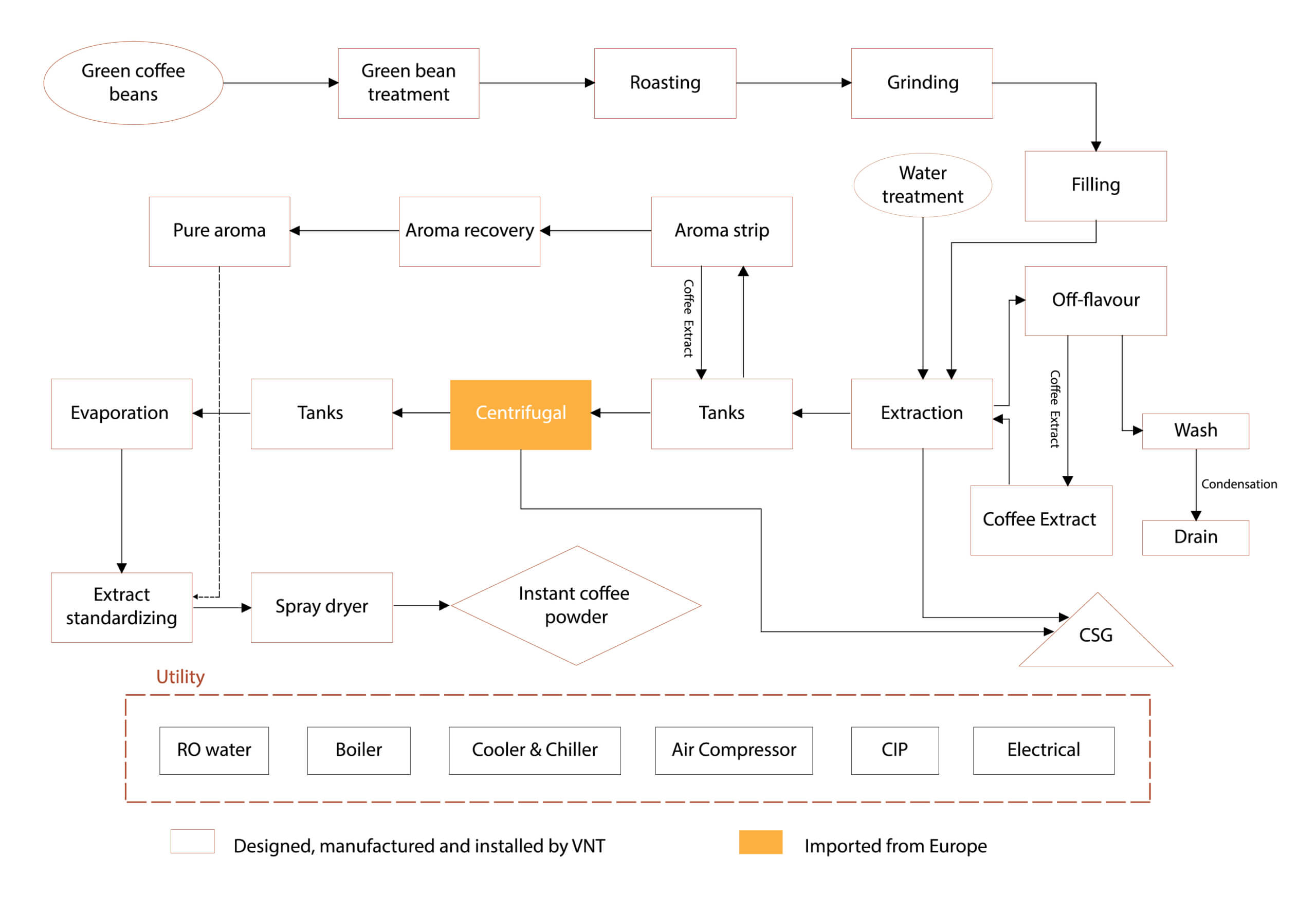

Making instant coffee is an art of balancing flavor and efficiency, with several key steps that need to be carefully managed. The main stages? Roasting, extraction, drying, and packaging—each one vital to preserving that rich coffee taste we all love.

- Roasting and Grinding: It all starts with picking the perfect beans and roasting them just right. Roasting and Grinding in the instant coffee manufacturing process is where the magic happens, transforming the chemical makeup of the beans to unlock those signature coffee flavors. Once roasted, the beans are ground, but not as finely as you’d expect from your typical ground coffee—here, a coarser grind preps them for the extraction process.

- Extraction: In the instant coffee manufacturing process, this is where the real flavor gets pulled out. Most manufacturers use percolation batteries, a fancy setup of 5 to 8 columns filled with ground coffee. Water flows through these columns in a countercurrent system—fresh water meets the most spent coffee grounds, and freshly roasted beans get the rich extract that’s already been through several columns. The first column gets water at 100°C, but the other columns get even hotter, with temperatures up to 175°C under pressure, ensuring maximum extraction of all those flavorful, soluble coffee solids.

- Soluble Content and Yield: The goal? A coffee extract with 20–25% soluble solids, which then gets dried to make instant coffee. Thanks to the high temperatures during extraction, instant coffee yields far more soluble goodies than your morning brew, including almost all the caffeine—compared to about 85% in traditional brewing.

Concentration of Extract

In the instant coffee manufacturing process, after extraction, the liquid coffee extract is concentrated before drying. This step boosts the efficiency of the drying process, reducing energy use while helping to lock in the coffee’s flavor.

- Evaporation: Most often, concentration happens through evaporation, where water is removed from the extract. Evaporators like plate and centrifugal film systems handle this job, minimizing exposure to high temperatures to protect the flavor. But there’s a catch: as water evaporates, volatile compounds that add to coffee’s flavor can be lost too.

- Multistage Evaporation: To be more efficient, manufacturers often run evaporation in stages, using heat from one stage to power the next. This reduces energy consumption and keeps things running smoothly.

- Freeze Concentration: Want to keep even more flavor? Freeze concentration is an alternative. Here, water is frozen out of the extract and separated as ice, preserving more of those volatile compounds. The downside? It’s less efficient and only reaches about 38% soluble solids due to the thickness of the extract. Despite its flavor-saving charm, freeze concentration isn’t as widely used as evaporation.

- Balancing Flavor and Efficiency: Manufacturers have to walk a fine line—getting a high concentration without sacrificing flavor. While higher concentrations speed up drying and make the coffee dissolve better, pushing it too far can lead to thick, syrupy coffee that’s hard to work with and may lose some of that prized flavor due to heat or escaping volatile compounds. It’s a tricky balance, but when done right, you get the best of both worlds: efficiency and a delicious, aromatic cup!

The coffee liquid is typically concentrated before drying to enhance efficiency and reduce the energy required for the drying process

Spray Drying

Spray drying is the go-to method in theinstant coffee manufacturing process, mainly because it’s quick, cost-effective, and can handle massive production volumes with ease.

- Process Overview: In spray drying process, the concentrated coffee extract is sprayed into a tall drying chamber through high-powered centrifugal nozzles. These nozzles break the liquid down into tiny droplets, which are then hit with hot air. As the droplets fall, the water evaporates, leaving behind fine coffee particles that collect as a powder. The average particle size is around 300 micrometers, giving the powder the perfect bulk density and making it easy to handle.

- Controlled Drying: Everything about this drying process is precisely controlled to achieve the right color and moisture level in the coffee. The final moisture content is kept below 5%, ensuring the coffee stays shelf-stable and safe from spoilage. Depending on the roast and extract concentration, the resulting spray-dried coffee powders can range from light to dark brown.

- Physical Properties: Spray-dried coffee is known for being free-flowing, meaning it’s easy to measure and dissolves smoothly in water. It’s designed to have a bulk density of 180–220 grams per liter—just right so that a semi-heaped teaspoon holds about 2 grams, enough to brew a standard 150-170 ml cup.

- Drawbacks of Spray Drying: While spray drying is super-efficient, it does have its downsides—mainly in the flavor department. The high heat involved in the process can lead to the loss of some of the volatile aroma compounds that give coffee its distinct flavor. To combat this, manufacturers often add coffee oils after drying to bring back some of that lost flavor.

Freeze Drying

Freeze drying, on the other hand, is the fancy, more delicate option when flavor is the top priority in the instant coffee manufacturing process. It’s slower and pricier, but freeze-dried coffee usually boasts a richer aroma and taste compared to spray-dried versions.

- Process Overview: Freeze drying starts with freezing the coffee extract into slabs or granules. These frozen pieces are then placed in a vacuum chamber, where they’re slowly warmed under a high vacuum (around 0.4 torr). This causes the ice to sublimate—going straight from solid to gas without becoming liquid first. The big win here? This method preserves the coffee’s structure and flavor, since it happens at low temperatures and avoids the high heat that can break down those precious volatile compounds.

- Granulation and Size Control: Before the drying begins, the frozen slabs are granulated into uniform particles. Any granules that are too big or too small are recycled until everything matches the desired size. These granules are comparable in size to the powder from spray drying but hold on to more flavor, thanks to the gentler process.

- Foaming Technique: Some manufacturers even get a bit creative with a foaming technique, introducing gases like carbon dioxide or nitrogen into the coffee extract before it’s frozen. This adds tiny air pockets, improving the texture and solubility of the final product.

- Advantages: Freeze drying really shines when it comes to flavor. The low temperatures help keep those delicate flavor compounds intact, making freeze-dried coffee more aromatic and flavorful. It also has a more porous structure, which means it dissolves more easily, even in cold water. So, if you’re looking for the best taste in your instant coffee, freeze drying is hard to beat!

Comparison Table Between Spray Drying and Freeze Drying In The Instant Coffee Manufacturing Process

| Criteria | Spray Drying | Freeze Drying |

|---|---|---|

| Process Overview | Coffee extract sprayed into hot air, forming powder | Coffee extract frozen, then sublimated to remove ice |

| Cost | Lower cost, efficient for large volumes | Higher cost, slower process |

| Flavor Retention | Some loss of volatile compounds due to heat | Better flavor retention due to low temperatures |

| Texture | Fine powder with smooth dissolution | Porous granules, dissolves easily |

| Moisture Content | Less than 5%, ideal for shelf stability | Similar low moisture content |

| Solubility | Dissolves quickly in water | Dissolves easily, even in cold water |

| Production Volume | Suitable for mass production | Less efficient for large scale |

| Final Product Quality | Good, but some loss in aroma and flavor | Superior aroma and flavor |

| Typical Use | Budget-friendly instant coffee | Premium instant coffee products |

Handling of Volatile Compounds

When it comes to the flavor and aroma of coffee, volatile compounds are the secret sauce of the instant coffee manufacturing process. But keeping them intact during the production of instant coffee is no easy feat—especially since these delicate compounds are highly sensitive to heat and can easily be lost during processes like spray drying and evaporation.

- Headspace Aroma: One of the earliest tricks to improve flavor retention was adding coffee oil to the finished product. Coffee oil, packed with volatile compounds, is sprayed onto the dried coffee powder to enhance its aroma. It’s like giving your coffee an extra boost of that fresh coffee smell. The oil comes from roasted beans or spent grounds and is purified to really max out its aromatic properties. While this makes the coffee smell fantastic, it doesn’t do much for the taste of the brewed cup—it’s more of an olfactory bonus.

- Steam Stripping and Prestripping: To catch those volatile compounds before they vanish, manufacturers use techniques like steam stripping. Here, steam removes the volatiles from roasted coffee before the extraction process begins. The volatiles are condensed into an aromatic essence, which can be added back to the final product later. Prestripping works similarly but happens after partial evaporation of water from the coffee extract. This technique captures those flavorful compounds just before they’re lost in the drying process, turning them into a liquid essence that can be reincorporated into the coffee.

- Reincorporation: After extraction or evaporation, the magic happens when that volatile essence is added back into the coffee extract. This small tweak ensures more flavor and aroma are locked into the final product, giving instant coffee a richer sensory experience.

- High-Solids Concentration: Another trick in the flavor retention toolbox is to use coffee extracts with a high concentration of soluble solids during spray drying. Why? Because higher solids mean faster drying and less exposure to heat, which helps protect those all-important volatile compounds. In freeze drying, getting the freezing parameters just right—like slowing down the process to form larger ice crystals—also helps. Bigger ice crystals trap more volatiles in the coffee during drying, making freeze-dried coffee a flavor-packed experience.

By fine-tuning these processes, manufacturers can capture more of the coffee’s essence, giving instant coffee a fuller aroma and taste.

Agglomeration

Agglomeration is the unsung hero of the instant coffee manufacturing process, taking those tiny coffee particles and turning them into larger, more uniform granules. This not only improves the coffee’s texture but also makes it dissolve more easily and look more appealing.

- Process Overview: The magic of agglomeration happens when dried coffee particles are re-wetted with steam or water, causing them to bond together into clusters. These newly formed granules are then re-dried, creating a more cohesive and user-friendly product. Larger particles have a big advantage—they dissolve faster and more smoothly in water compared to fine powders, making your coffee experience much more enjoyable.

- Instantization: Originally used for making skim milk powder more soluble (a process called “instantization”), this technique is now a staple in instant coffee production. The resulting granules are less dusty, more durable, and dissolve quickly, elevating the convenience factor for consumers.

- Minimal Impact on Flavor: While agglomeration adds an extra step, it doesn’t mess with the coffee’s flavor. The process focuses mainly on improving the physical properties of the coffee, so your cup dissolves quickly and evenly, without sacrificing any of the coffee’s aromatic goodness.

Packing and Shelf Life

When it comes to instant coffee manufacturing process, good packaging is key to keeping that flavor and aroma fresh. Since instant coffee is hygroscopic (it loves to soak up moisture), improper packaging can lead to clumping and loss of its free-flowing magic.

- Glass Jars and Tins: While tins were once the go-to, glass jars have reigned supreme since the 1960s. Why? Because glass provides an airtight seal that keeps moisture and oxygen at bay, protecting the coffee from going stale or losing its zing.

- Low-Oxygen Packaging: Oxygen is a major threat to instant coffee’s flavor, especially when it comes to those delicate volatile compounds that make your cup so aromatic. To tackle this, many manufacturers use low-oxygen packaging, keeping oxygen levels below 4%. Techniques like vacuum sealing or gas flushing (with nitrogen or carbon dioxide) push out the oxygen, safeguarding the oils and flavors that make your coffee sing.

- Coffee Oil Aroma Enhancement: To really wow you when you first pop open that jar, some manufacturers spray a touch of coffee oil inside just before sealing. This doesn’t do much for the flavor of the brewed coffee, but it gives that delightful freshly roasted smell when you open the jar—an instant pick-me-up!

- Packaging Materials: Glass jars are still the gold standard because they seal tightly, don’t mess with the coffee’s delicate compounds, and are sturdy enough to handle the rigors of storage. For budget-conscious options, laminated foil packs are sometimes used, but they aren’t as good at keeping oxygen out over the long haul.

- Shelf Life: Properly packaged instant coffee, especially the simple spray-dried kind, can last for years if kept in a cool, dry spot. For those more premium products that contain extra volatile compounds (like coffee oil-enhanced varieties), shelf life usually caps out at 18 months. These need a bit more TLC to avoid oxidation or moisture absorption, which can shorten their lifespan.

- Storage Conditions: Instant coffee loves to absorb moisture from the air, which can cause clumping and make it harder to measure and dissolve. To keep it in top shape, always store it in a tightly sealed jar in a cool, dry place. The relative humidity around it should be kept below 35–40% to preserve its texture and flavor.

Proper packaging is essential for preserving the quality of instant coffee

Storage and Stability

Maintaining the quality of instant coffee over time is a delicate balance in the instant coffee manufacturing process due to its hygroscopic nature. The key to ensuring long-lasting flavor and texture lies in effectively managing moisture and oxygen exposure during both production and storage.

- Moisture Control: Instant coffee needs to be dried to a moisture content of less than 5% during production to prevent clumping and stickiness. But even after this, it can absorb moisture if the surrounding air is too humid. For long-term storage, it’s crucial to maintain a relative humidity below 35–40%, depending on the coffee’s specific properties. When moisture levels rise above this threshold, the coffee can begin to cake, degrade in quality, and lose its free-flowing nature.

- Oxidation of Volatile Compounds: Oxygen exposure is another major threat to instant coffee, particularly to its volatile compounds, which are responsible for the coffee’s flavor and aroma. If not carefully controlled, oxygen can cause these compounds to oxidize, resulting in a stale or flat taste. To combat this, manufacturers use low-oxygen packaging techniques, ensuring that the coffee remains fresh for as long as possible. Products with added coffee oils or other flavor enhancers are especially sensitive to oxygen, so they are often packed in an atmosphere with reduced air exposure.

Know More:- tower dryer | wood chip drying system | aroma recovery - Shelf Life Considerations: Basic, spray-dried instant coffee with fewer volatile compounds can have a shelf life of several years if kept dry and sealed properly. However, more complex products, such as those treated with coffee oils to boost flavor, tend to have a shorter shelf life of around 18 months. This is because the volatile compounds in these products are more prone to oxidation and moisture, necessitating careful packaging and storage.

- Consumer Storage: Once a jar of instant coffee is opened, it’s important to store it in a cool, dry place to maintain its flavor and aroma. To keep the coffee at its best, consumers should tightly close the jar after each use to minimize exposure to air and humidity. In humid climates, storing the coffee in the refrigerator can help, although this poses the risk of condensation forming when the coffee is taken out of the fridge, potentially introducing moisture into the jar.

Ready to elevate your business instant coffee manufacturing process? Contact our experts today!

Conclusion

The instant coffee manufacturing processes or soluble coffee manufacturing processes is a complex and intricate one, involving multiple steps to ensure the final product is both convenient and flavorful. For coffee business owners, understanding this process can provide valuable insights into the quality and efficiency of their production methods. By leveraging advanced technologies and systems, such as our Instant Coffee Extraction System, Aroma Recovery System, Evaporation System, and Spray Dryer Technology, businesses can produce high-quality instant coffee that meets consumer demands while preserving the essence of traditional coffee.

FAQ

1. What is the instant coffee manufacturing process?

The instant coffee manufacturing process involves roasting, grinding, extracting, concentrating, and drying coffee beans to create soluble coffee granules or powder that dissolve in water.

2. What are the main methods for drying instant coffee?

The two main methods are spray drying and freeze drying. Spray drying is faster and cost-effective, while freeze drying preserves more flavor and aroma.

3. How is flavor retained in the instant coffee process?

Flavor is preserved by using methods like freeze drying, which operates at lower temperatures, and by reincorporating coffee oils and volatile compounds that enhance aroma.

4. Which drying method is better for preserving coffee flavor?

Freeze drying is generally better for preserving the flavor and aroma of coffee compared to spray drying, which uses higher temperatures.

5. Why is instant coffee hygroscopic?

Instant coffee is hygroscopic, meaning it absorbs moisture easily. This is why it’s important to store it in a cool, dry place with airtight packaging.

6. How long does instant coffee last?

Instant coffee can last several years if properly sealed and stored. Premium products with added volatile compounds may have a shelf life of 18 months.